What Are Aluminum Sheet Magnesium?

Aluminum sheet magnesium usually refers to 5xxx aluminum alloys, including 5052, 5086, 5083,5754,etc. They features lightweight and good corrosion resistance. 5052 H32 is very popular. Learn more.

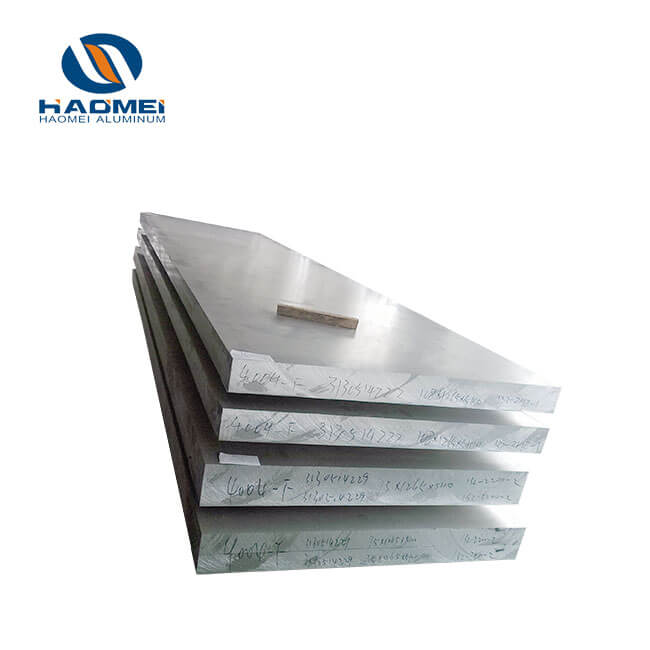

Aluminum sheets magnesium are alloy plates composed of aluminum as the matrix and a certain proportion of magnesium elements. They mainly cover 5 series aluminum alloys. Common grades include 5052, 5086, 5083, 5754, etc. They are widely used in aerospace, transportation, architectural decoration and other fields.

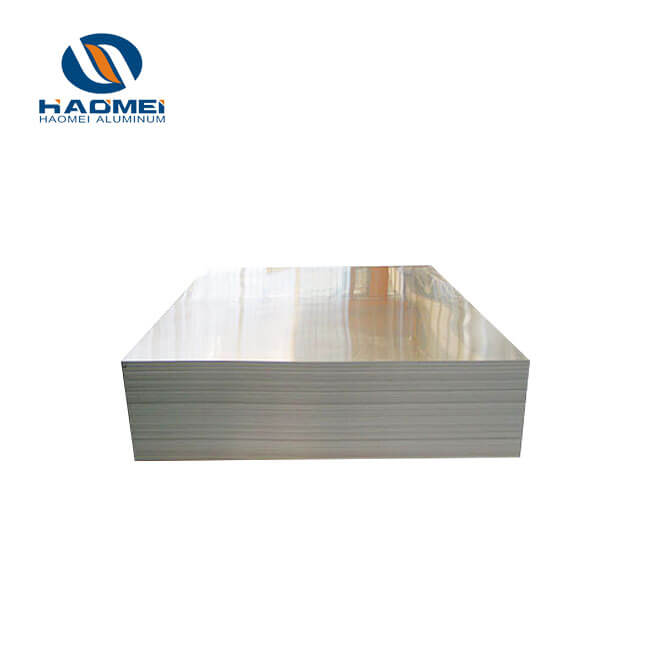

Aluminum-magnesium alloy plates have a series of significant characteristics. Lightweight is its outstanding advantage. Aluminum itself has a low density. After adding magnesium, it further reduces weight while ensuring strength. This is of great significance to the weight-sensitive aerospace and automobile manufacturing industries. It can effectively reduce energy consumption and improve operating efficiency.

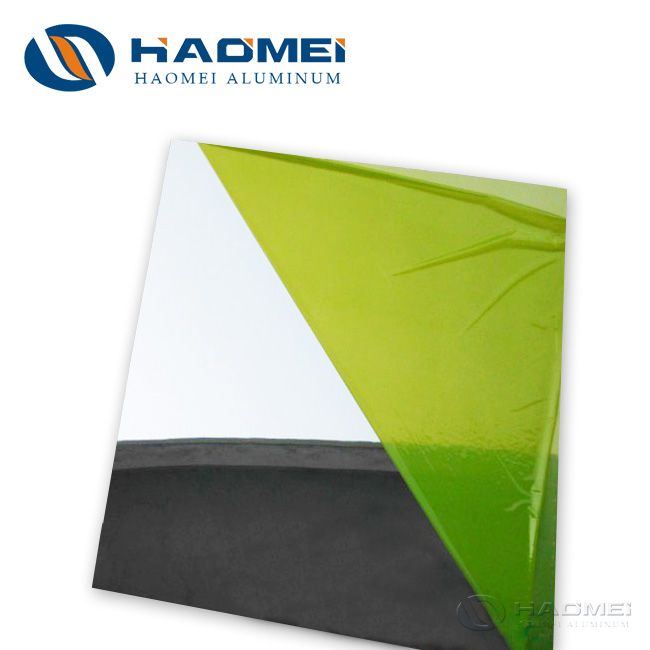

Its corrosion resistance is also excellent. Magnesium enhances the stability of the oxide film on the surface of the alloy. Even in harsh environments such as humidity and salt, it can maintain a good state for a long time. For example, seaside buildings use aluminum-magnesium alloy plates as decorative materials, which can effectively resist sea breeze erosion.

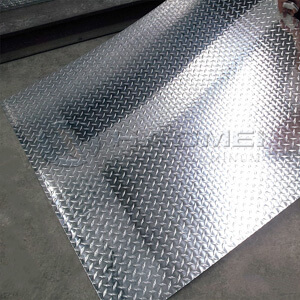

In addition, this type of alloy plate also has good processing performance, easy to perform stamping, bending, welding and other operations, and can meet the complex design requirements of different products.

Among many aluminum-magnesium alloy plates, 5052 H32 performs particularly well. In 5052 H32, "5052" represents the alloy grade, and "H32" indicates its work hardening state and stabilization treatment.

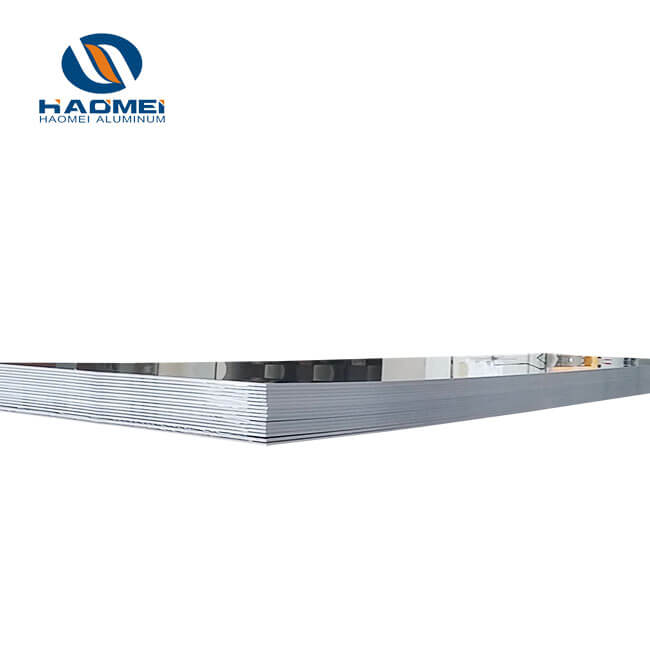

In terms of performance, it has moderate strength, with a tensile strength between 170 and 240MPa and a yield strength of about 145MPa. It has good toughness and ductility, and can withstand external deformation to a certain extent without breaking.

Excellent corrosion resistance is the core competitiveness of 5052 H32. The dense oxide film formed on its surface can effectively resist corrosive media such as the atmosphere and seawater. In the field of shipbuilding and marine engineering, 5052 H32 is often used to manufacture hull structural parts, pipelines, etc., which greatly reduces maintenance costs and safety hazards caused by corrosion.

In terms of processing performance, 5052 H32 can easily complete cold processing operations such as bending and stretching, and the surface quality of the plate after processing is high, without too much subsequent processing. It is suitable for manufacturing parts with complex shapes, such as automobile fuel tanks and electronic equipment housings.

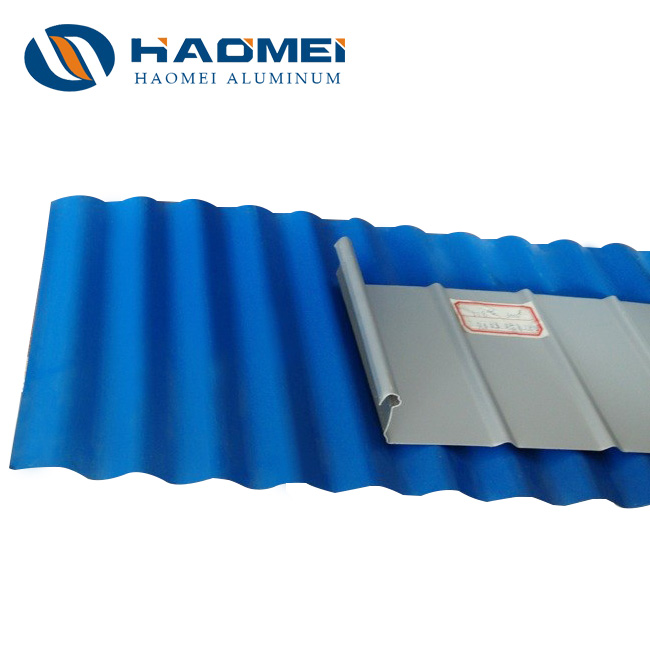

In actual application scenarios, 5052 h32 aluminum plays an irreplaceable role. In the field of construction, it can be used as decorative materials such as curtain wall panels and ceilings. It is not only beautiful, but also can maintain its color and performance for a long time.

In the transportation industry, it is often used to manufacture automotive parts, light rail carriages, etc., to help achieve vehicle lightweighting and improve fuel economy. In the electronics and electrical industry, it has become an ideal choice for electronic equipment casings due to its good processing performance and electromagnetic shielding performance.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China