5052 Aluminum Sheet/Plate belongs to Al-Mg alloy with magnesium as its main alloy elements. Of other alloy elements, chromium has similar effect with manganese which improves he resistance to stress corrosion cracking, improves the strength of the base metal and weld, and reduces the tendency of weld cracking. We have another 5083 aluminum plate for sale.

Properties of 5052 Aluminum Plate

Application of 5052 Aluminum Sheet

1. It has broad application, especially for construction.

2. It is used for making the stamping parts of vehicles, ships and instruments, rivets, hardware products, electrical enclosures.

3. It can also be used to manufacture aircraft fuel tanks, oil pipes, aerospace aluminum alloy materials.

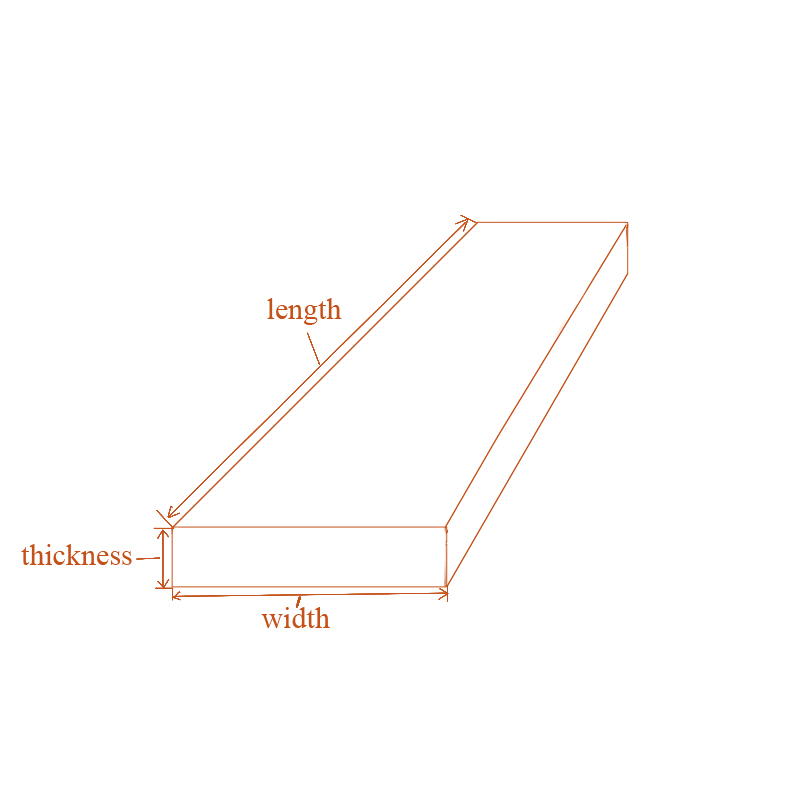

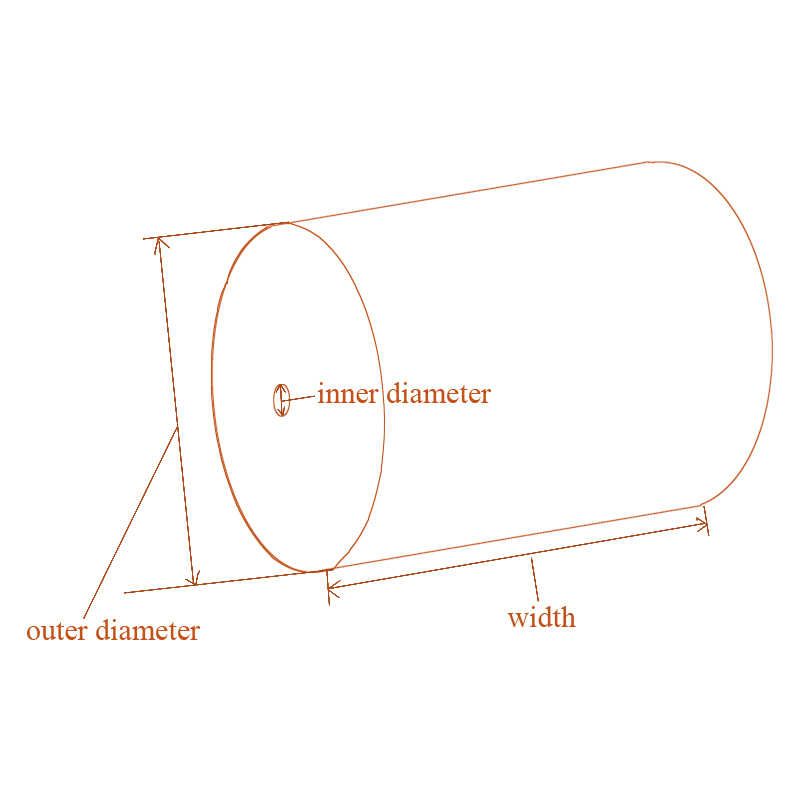

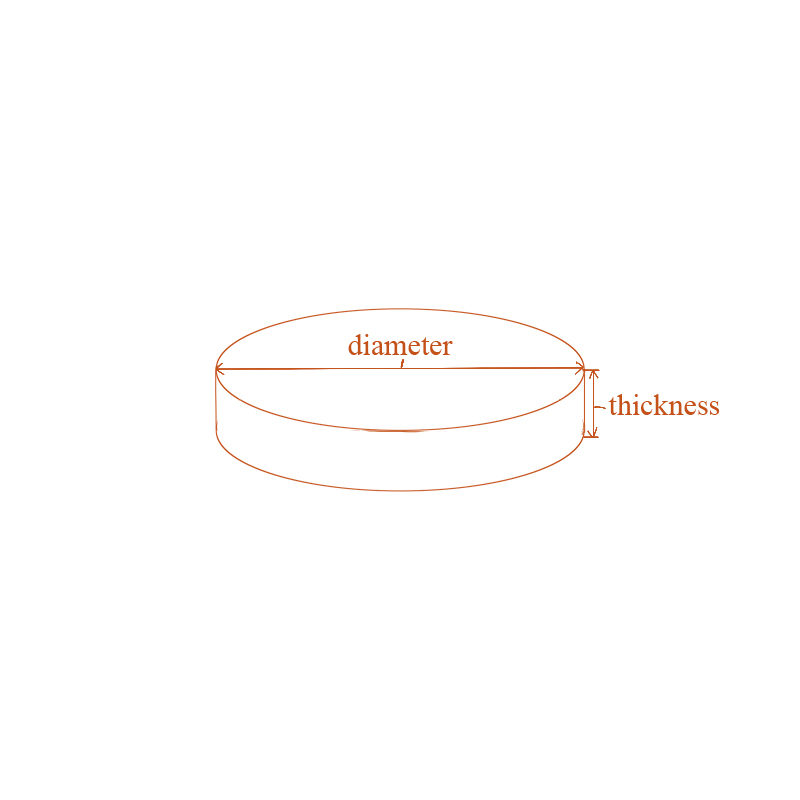

Alloy | Temple | Thickness (mm) | Width (mm) | Length (mm) |

5052 aluminum sheet | O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H32, H34,H36,H38,H111, H112,H114,H 116,H321 | 0.15-600 | 20-2600 | 500-16000 |

5052 aluminum plate | O,H111,H12,H14,H16,H18,H22, H24,H26,H38,H112,F | 0.15-350 | Below 2200 | Below 12000 |

Typical Mechanical Properties of 5052 Aluminum Sheet

Temper | Tensile Strength KSI | Yield Strength KSI | Elongation % |

5052 HO/H111 | 173-213 | 66 (min) | 15 (min) |

5052 H32/H22 | 214-262 | 159 (min) | 4 (min) |

5052 H34/H24 | 235-282 | 180 (min) | 3 (min) |

5052 H36/H26 | 256-303 | 200 (min) | 2 (min) |

5052 H38/H28 | 269(min) | 221 (min) | 2 (min) |

Chemical Composition Limits (WT %)

Magnesium | 2.2%-2.8% by weight |

Chrominum | 0.15%-0.35% maximum |

Copper | 0.1% maximum |

Iron | 0.4% maximum |

Manganese | 0.1% maximum |

Silicon | 0.25% maximum |

Zinc | 0.1% maximum |

Other each | 0.05% maximum |

Others total | 0.15% maximum |

Remainder | Aluminium |

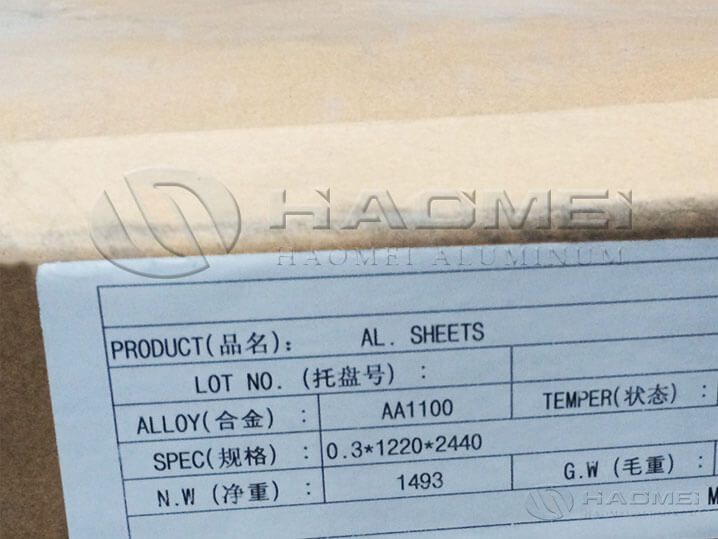

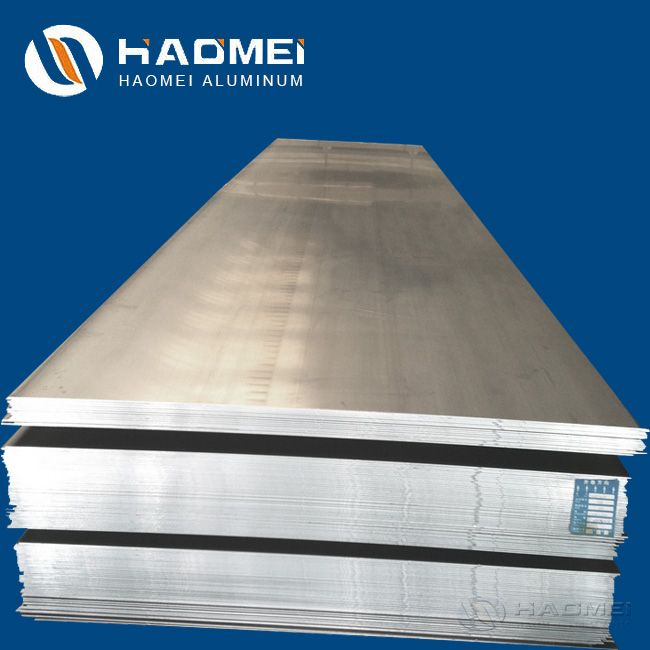

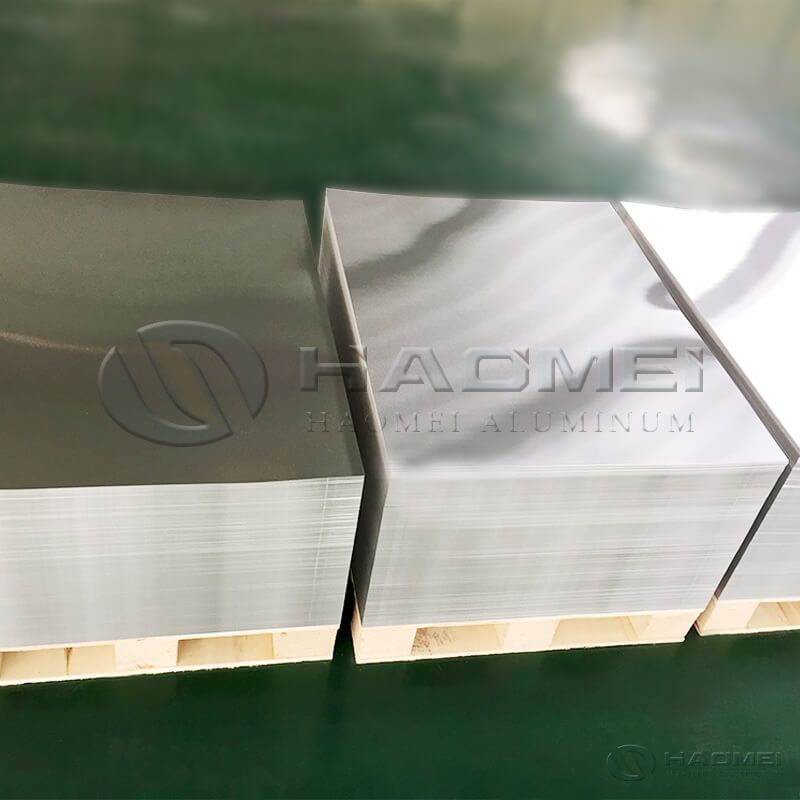

5052 Aluminium Panel Sheet Show