What is aluminium plate for tanker

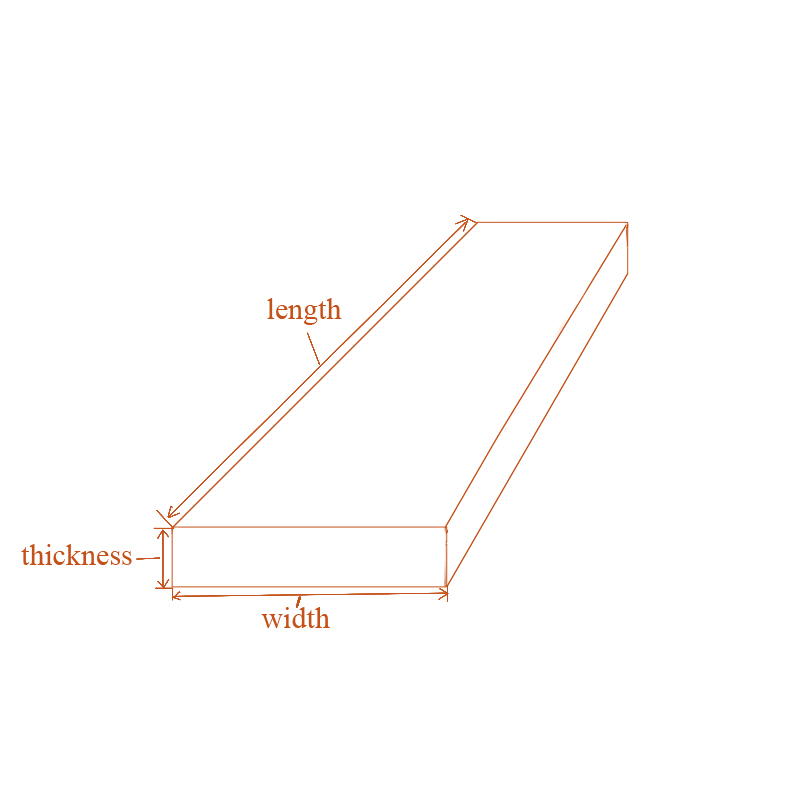

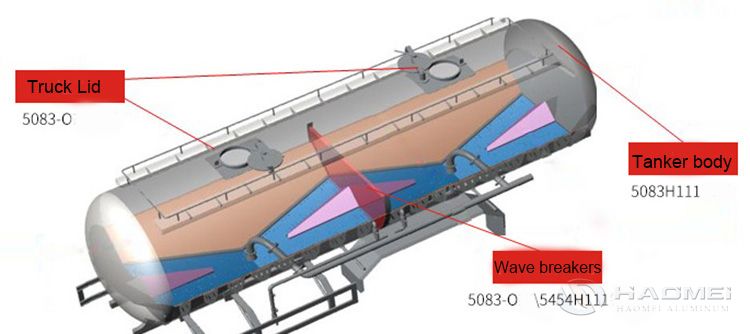

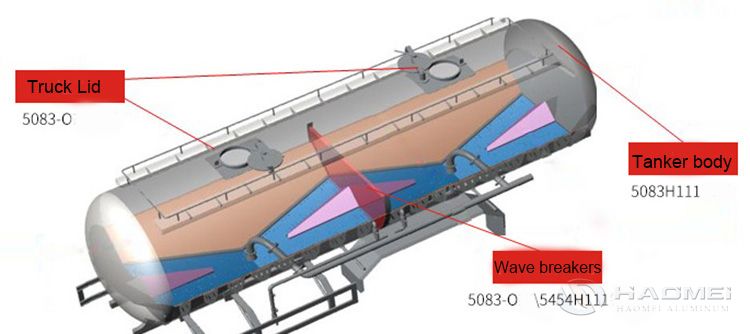

A tanker is used to carry various liquids, liquefied gases, and powdered goods. The aluminum alloy tanker body is composed of hoarding, wave breakers and tank ports.The common plate for tanker is generally within 12.5 meters in length and less than 2.2 meters in width. The common thicknesses are generally 5, 6, 7, and 8mm. Haomei Aluminum offers 5083, 5052, 5754, 5454, 5182,etc.

The main applications of aluminium tanker plate

Tanker body: The 5083H111 aluminum plate is used for the tanker body. 5083-O aluminum plate is used for the truck lid for the lids on both sides need bending. 5454H111 aluminum plates are also used for the tanker body.

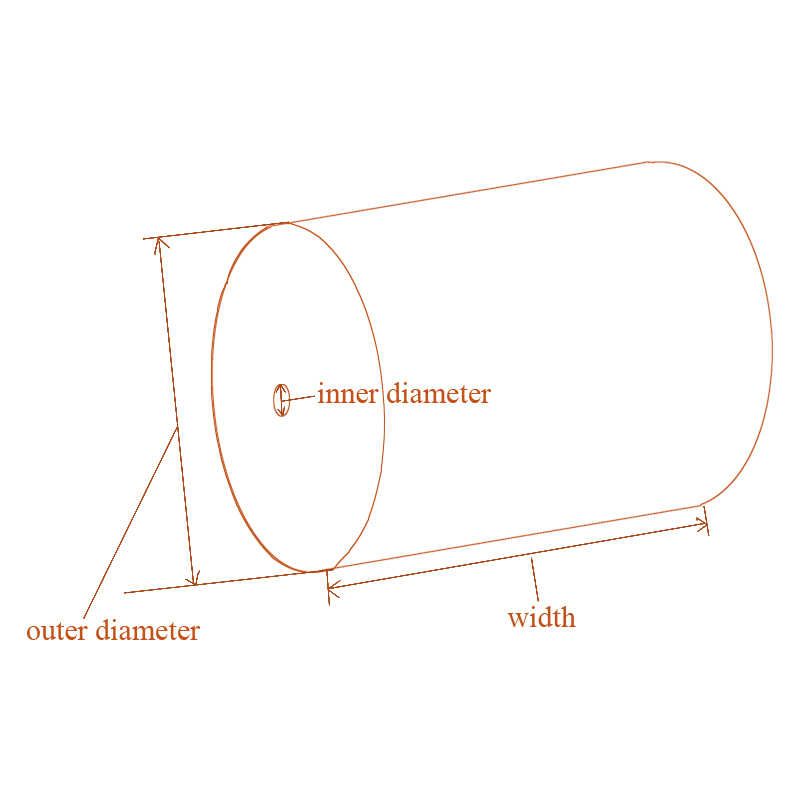

Cylinder: Aluminum alloy automobile air storage cylinders feature good corrosion resistance, light weight, good economic benefits and high recycling rate. 5083 aluminum plate is widely used in making tanker cylinder.

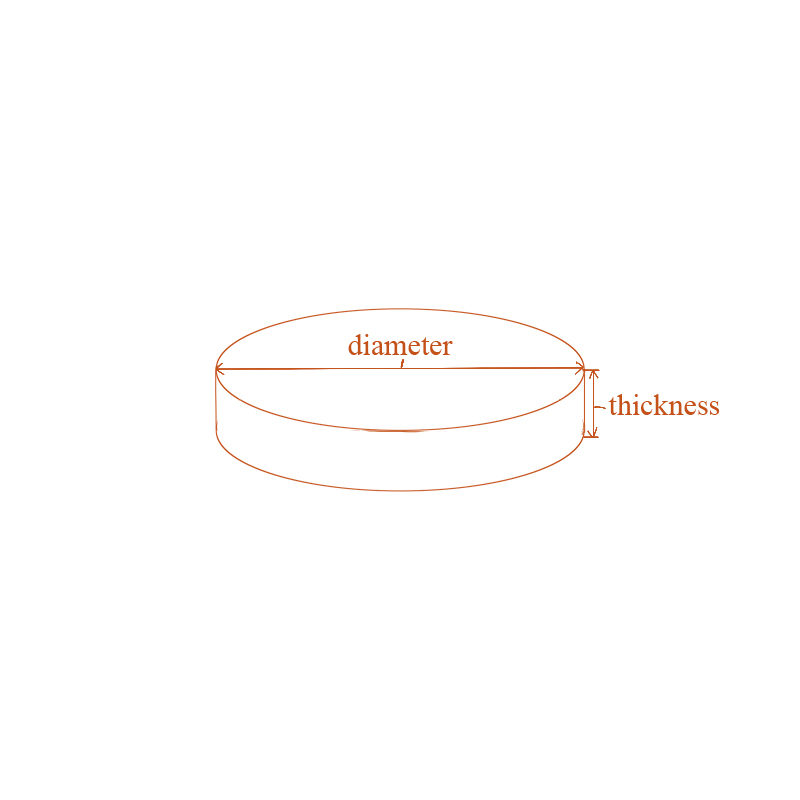

Fuel tank: With the mass production of tank trucks, problems such as how to save fuel and production cost have risen. 5052 aluminum sheet for fuel tank is energy-saving, environmentally friendly and long-lasting.

5182 aluminum is used to produce the latest high-magnesium alloy tanker which was born for the European road dangerous goods transportation agreement in recent years. Its tensile strength and elongation are relatively high.

LNG storage tank: The volume of liquefied natural gas (LNG for short) is 1/600 of the gaseous state, which makes the material requirements for LNG storage tanks higher. Aluminum alloy 5083 is used for this application.

Specification of the aluminium tanker plate

Alloy | Thickness(mm) | Width(mm) | Length(mm) |

5083 | 2.0-8.0 | 1000-2000 | 2000-12600 |

5052 | 2.0-8.0 | 1000-2000 | 2000-12000 |

5754 | 2.0-8.0 | 1000-2000 | 2000-12000 |

5454 | 2.0-8.0 | 1000-2000 | 2000-12000 |

5182 | 4.0-7.0 | 980-2200 | 800-9000 |

The chemical element of aluminum plate for tankers

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others |

Each | Total |

5083 | 0.20 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.10 | 0.25 | 0.10 | 0.05 | 0.15 |

5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 |

| 0.05 | 0.15 |

5754 | 0.40 | 0.40 | 0.10 | 0.05 | 2.6-3.6 | 0.30 | 0.20 | 0.15 | 0.05 | 0.15 |

5454 | 0.25 | 0.40 | 0.10 | 0.50-1.0 | 2.4-3.0 | 0.05-0.20 | 0.25 | 0.20 | 0.05 | 0.15 |

5182 | 0.20 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.10 | 0.25 | 0.10 | 0.05 | 0.15 |

Alloy | Temper | Tensile strength | Yield strength | Elongation |

5083 | O/H111 | ≥275O | ≥125 | ≥15 |

H112 | ≥275 | ≥125 | ≥12 |

5052 | O/H111 | 170-215 | ≥65 | ≥16 |

H112 | ≥190 | ≥80 | ≥7 |

5754 | O/H111 | 190-240 | ≥80 | ≥16 |

H112 | ≥190 | ≥80 | ≥7 |

5454 | H32 | ≥250 | ≥180 | ≥8 |

5182 | O/H111 | ≥280 | ≥125 | / |

Why Choose Haomei Aluminum

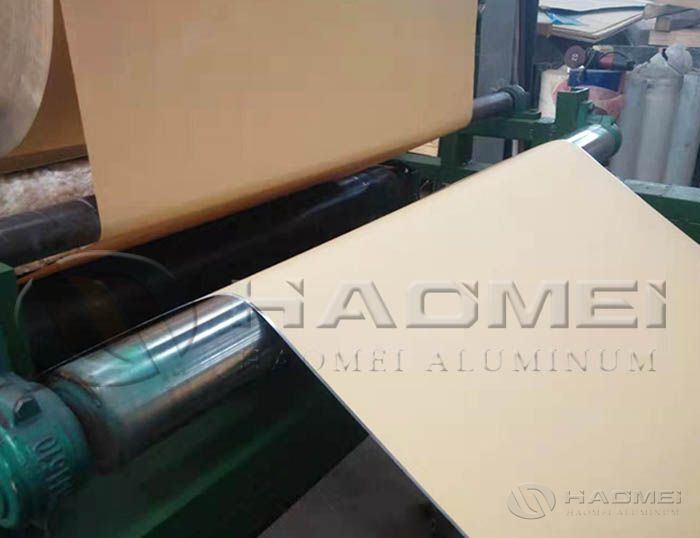

1. We have developed 1+4 hot rolling production line. In addition, Haomei Aluminum has 6 semi-continuous casting production lines, 10 continuous casting and rolling production lines, and 44 other large-scale processing equipment, providing a strong basis for the large-scale aluminum sheet production.

2. Haomei Quality Inspection Center has set up advanced quality inspection laboratories in the industry: chemical analysis laboratory, oil analysis laboratory, spectral analysis laboratory, tensile laboratory, micro analysis laboratory, etc., strictly controlling the production materials and strictly monitoring the production process.