The Use of 5 Series Aluminum Sheet in Automobile and Shipbuilding Industry

5000 series aluminum sheets are of wide application in automobile and shipbuilding industry. What requirements should they satisfy? For marine applications, they should have certificates.

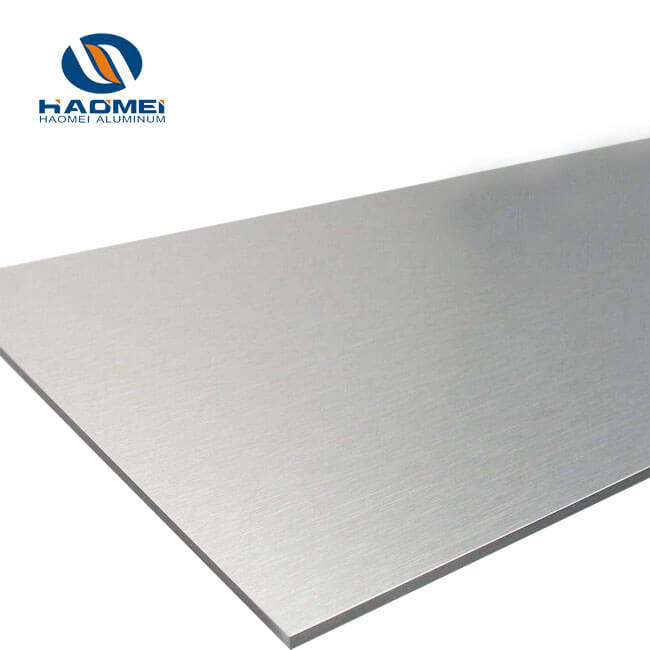

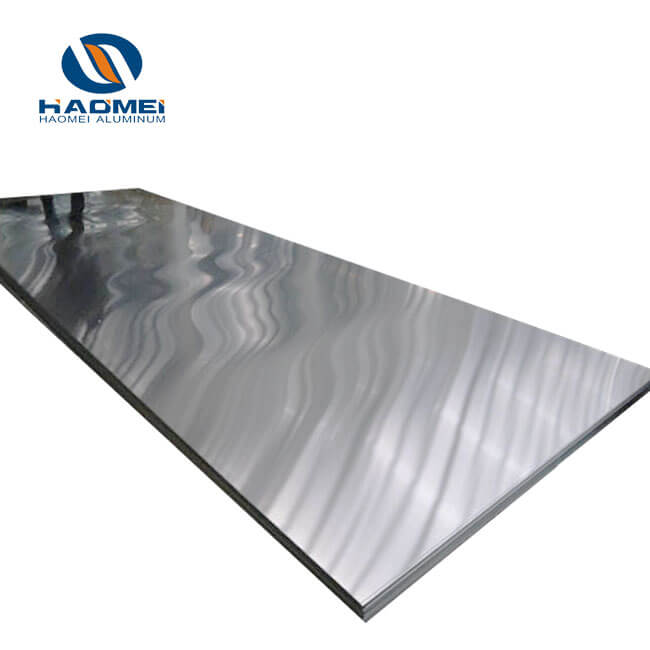

5000 series Al-Mg alloy has been widely used in marine environments due to its low density, high specific strength, and good corrosion resistance. It is an ideal material for manufacturing light high-speed ships. The typical marine grade aluminium sheets are 5083, 5052, 5086, 5059,etc. They all got the certification of class society.

A classification society is an organization that establishes and maintains relevant technical standards for the construction and operation of ships and offshore facilities. The main business of the classification society is to conduct technical inspections of new ships. Those who pass the test will be given various safety facilities and corresponding certificates.

When our marine grade aluminium 5083 applied for DNV, its surveyor fully affirmed the company's on-site management, process execution, production control, inspection and testing capabilities, product quality system, etc. After on-site review and various tests on the final product, our 5083 aluminum sheet met the requirements of classification society specifications and successfully passed the factory approval.

5xxx aluminum sheet also has wide application in automobile manufacturing industry. For this application, the aluminum sheet needs to satisfy the following requirements:

1. Good formability

The formability of an aluminum sheet refers to its ability to withstand shape changes during the stamping process. Formability can be evaluated by a formability test. The formability test results of aluminum alloy sheets can fully meet the performance needs of automobiles.

2. Certain anti-aging stability

The characteristic that aluminum alloy plates do not age when stored at room temperature is called anti-aging stability. Because aging will cause the alloy to elongate at the yield point during tensile deformation, that is, Lüde ribbon, which will cause uneven surface deformation and wrinkles during stamping.

The automotive aluminum sheet often needs some time to be transported and stored from the factory to the stamping of parts. Aluminum plates are usually required to be stored at room temperature for 6 months without aging.

3. Good baking hardening properties

Automotive stamping parts will also undergo aging when they are painted and baked after stamping, resulting in an increase in yield strength called bake hardening. High bake hardenability will give the part high dent resistance.

4. Good flanging ductility

When the automobile exterior cover is stamped and flanged, the plate's resistance to cracking is called flanging ductility. Therefore, aluminum alloy plates are required to have good flanging ductility to ensure that cracking does not occur during flanging.

The flanging ductility can be tested by cold bending test, but the usual cold bending does not take strain rate sensitivity into consideration, while the deformation is faster and the strain rate is larger during stamping and flanging, which puts higher requirements on flanging ductility.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China