Aluminum Sheet Insulation for Pipeline Protection

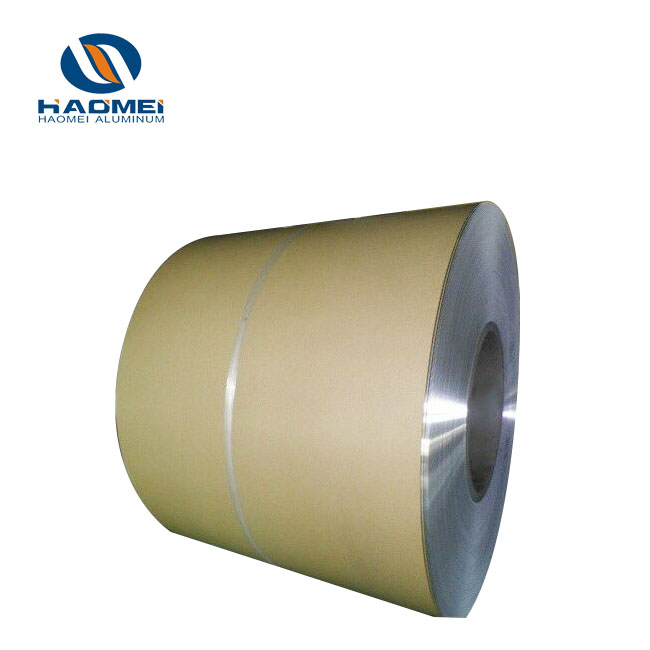

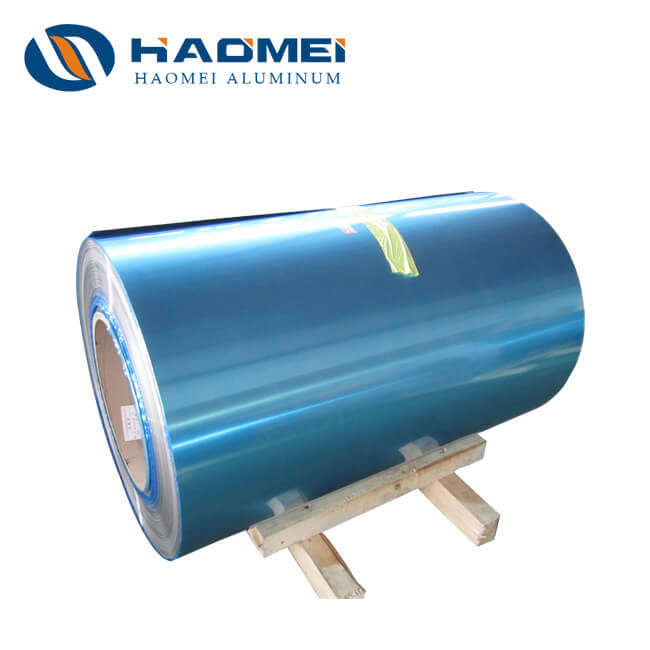

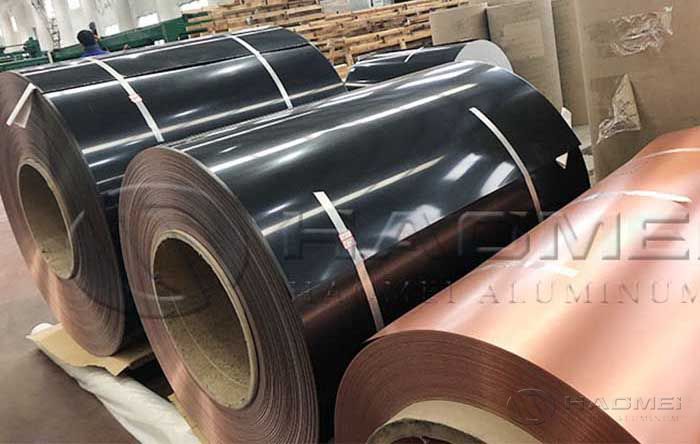

Aluminum sheet insulation can be used for pipeline protection like aluminum flat sheet with polykraft moisture barrier. There are different types of aluminum insulation sheets like PolySurlyn laminated aluminum coil.

There are different kinds of aluminum sheets, one of which is aluminum sheet insulation. It can be seen in many situations such as pipe laying. Why is the aluminum insulation sheet used for pipeline instead of iron sheets?

It needs to start from the environment of pipeline laying. Our common pipeline laying is basically an exposed environment, so there is a need for a material that can well meet the various properties required for pipeline laying such as weather factors, cost factors, and usage factors.

The advantage of iron sheet is its low production cost and high strength. The disadvantage is that the iron sheet material reacts easily with water and oxygen in the air due to its active chemical reaction. Therefore, iron sheet materials are very easy to rust and corrode under acid and alkali conditions. As an auxiliary material for pipeline laying, these characteristics are undoubtedly fatal.

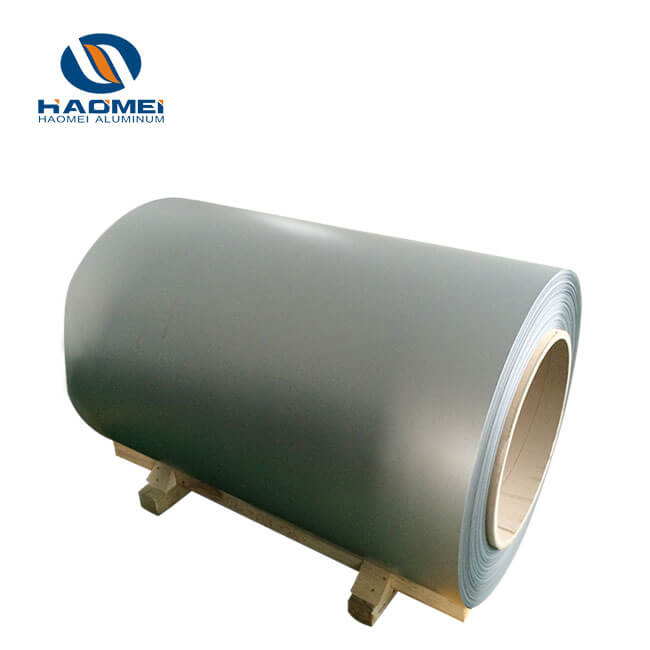

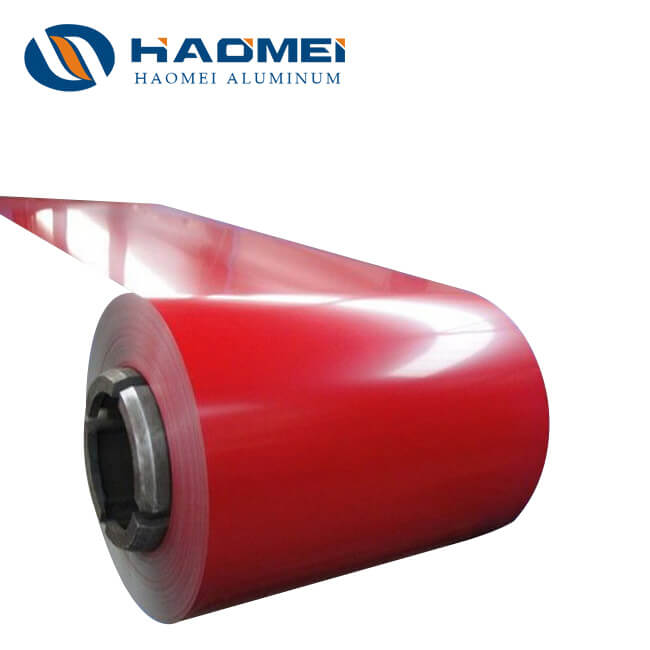

The surface of the aluminum insulation sheet has a very good metallic texture and is easier to integrate with various organic coatings. It has excellent anti-rust and anti-corrosion properties, and has a long service life. It is lighter and easier to install compared with iron sheets.

In terms of material price, thermal insulation aluminum sheet also has an advantage. The aluminum sheet processing technology is not very complicated, optimizing the process and the difficulty of coordination between processes, which not only improves production efficiency, but also reduces production costs.

Types of aluminum sheet

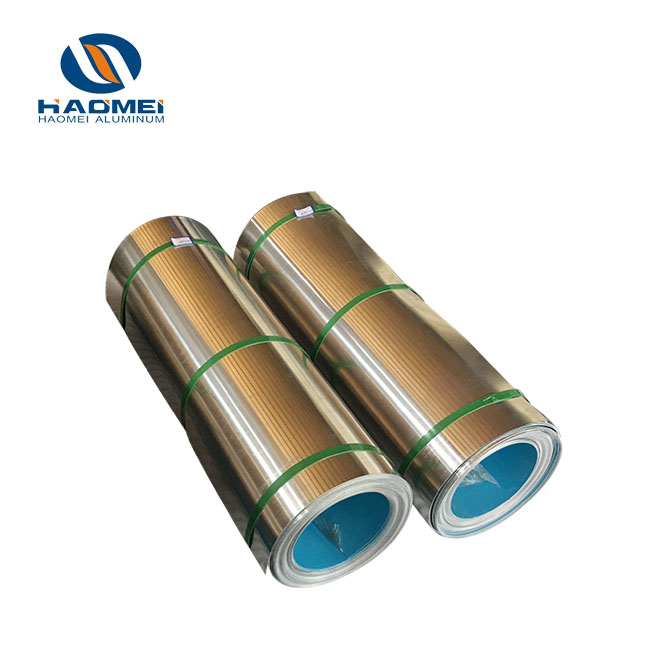

1. According to the laminated material, it can be divided into Aluminium flat sheet with Polykraft moisture barrier and PolySurlyn laminated aluminum coil. Haomei Aluminum also has polykraft laminted aluminum coil.

2. The aluminum sheet can be divided into cold rolling and hot rolling according to different processing techniques.

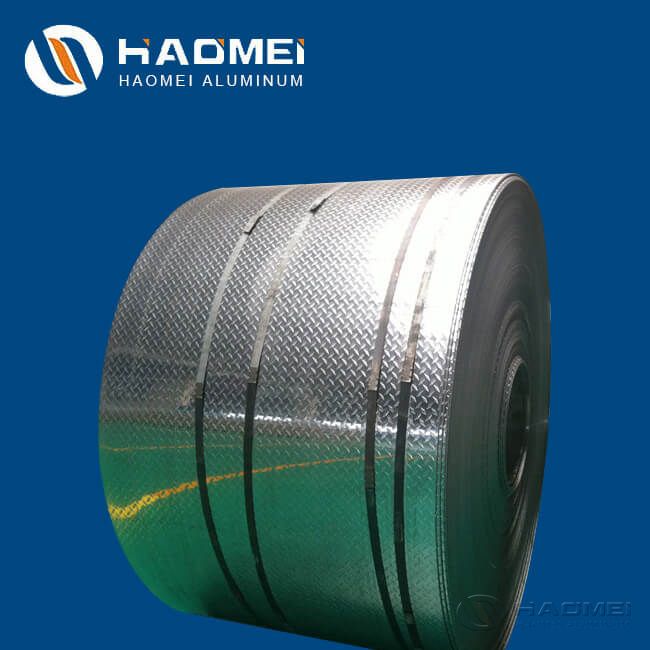

3. Embossed insulating aluminum panels are aluminum products that form various patterns on the surface through rolling processing based on insulating aluminum panels. They are widely used in packaging, construction, curtain walls, etc.

4. Mirror thermal insulation aluminum plate: refers to the thermal insulation aluminum plate that is processed by various methods such as rolling and grinding to give the surface of the plate a mirror effect.

5. Anodized aluminum insulation sheet: The thermal insulation aluminum plate is formed by placing the thermal insulation aluminum plate in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, and electrolysis is performed under specific conditions and the action of external current.

6. Brushed aluminum sheet: The manufacturing process of repeatedly scraping out lines from the insulation aluminum plate with sandpaper is divided into three parts: deesterification, sand grinder and water washing.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China