How To Control 8mm Aluminium Plate Thickness Tolerance

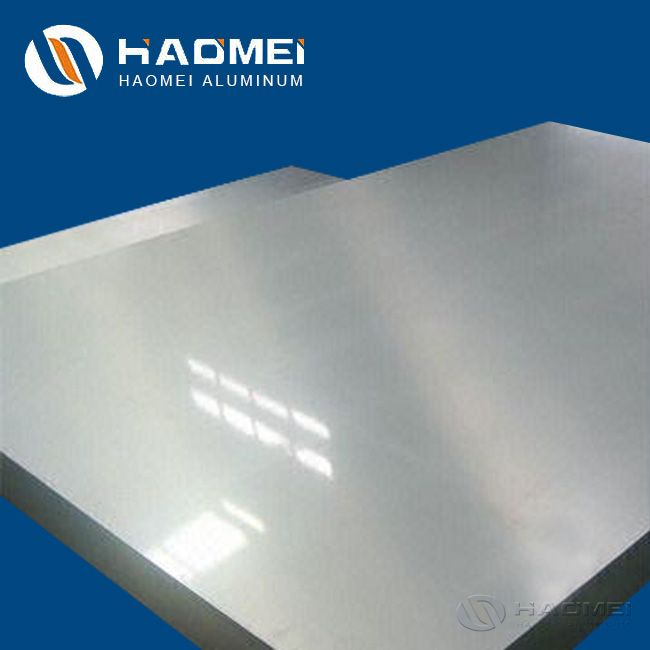

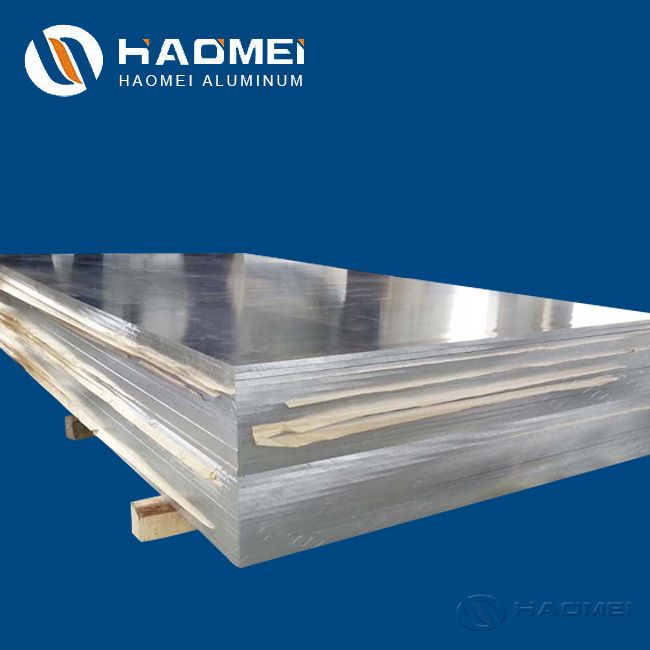

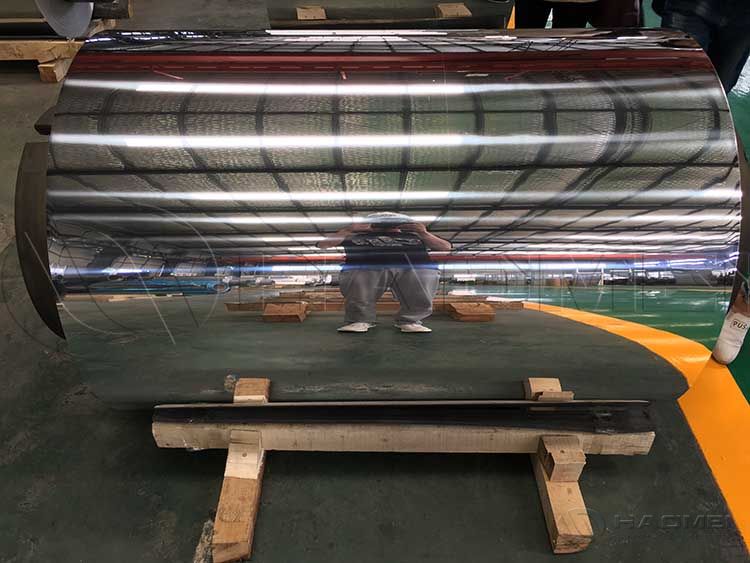

8mm aluminium plate is widely chosen as the marine grade aluminum sheet and aluminum tread plate. How to control its thickness tolerance? Lets have a look together.

8mm aluminium plate is widely chosen as the marine grade aluminum sheet and aluminum tread plate. How to control its thickness tolerance? Lets have a look together.

What is Definition of aluminum plate thickness deviation

Aluminum plate thickness deviation refers to the difference between the actual thickness of the aluminum plate and the specified thickness during the actual production process. This difference may be caused by various factors such as materials, equipment, and processes in the manufacturing process. According to different application fields and requirements, the thickness deviation value of the aluminum plate needs to be controlled within a certain range. Common aluminum plate thickness deviation values are ±0.05mm, ±0.1mm, ±0.2mm, etc.

Why is aluminum plate thickness deviation produced

Since the fluctuation of material thickness cannot be avoided during the production of aluminum plates, a certain range of thickness tolerance is caused. This tolerance is usually affected by factors such as raw material quality, production process and equipment accuracy.

Aluminum plates need to go through multiple process links such as rolling, quenching and stretching during the manufacturing process. Improper operation or insufficient equipment accuracy in these process links may affect the thickness of the aluminum plate, resulting in thickness deviation.

During the forming process of the aluminum plate in the mold, the mold precision and the quality of aluminum plate surface treatment will affect the thickness of the aluminum plate. Wear, deformation of the mold or unevenness of the aluminum plate surface may cause changes in the thickness of the aluminum plate.

Impact of aluminum plate thickness deviation

Aluminum plates with large thickness deviation may reduce production efficiency and output. Excessive thickness deviation of aluminum plates may cause problems with product performance and quality. The processing and adjustment of plate thickness deviation will also increase production costs.

Control method of thickness deviation of aluminum plate

Ensure that the quality of raw materials meets production requirements and reduce thickness deviation caused by raw material quality.

Optimize production process flow and improve equipment accuracy and process level.

Regularly inspect and repair molds to ensure their accuracy and integrity. At the same time, strengthen the lubrication and cooling measures of the mold to reduce the thickness deviation caused by mold wear and deformation.

Strengthen detection and adjustment measures during the production process. Through precise measurement and feedback systems, timely discover and adjust the thickness deviation of aluminum plates to ensure the stability and consistency of product quality.

In terms of thickness tolerance, Haomei Aluminum can control it around 0.1mm. Usually, medium and thick aluminum plates are molds and mechanical parts. Milling planes are required later. It is estimated that our company usually moves within the tolerance range. Welcome to leave message below to inquire aluminium plate cost from us.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China