How Is Friction Welding Aluminum Plate for Shipbuilding Produced

Friction stir welding aluminum plates can shorten the production cycle by 15%~25%, reduce welding variables, and produce no arc light or fume emissions, meeting the environmental protection requirements of shipbuilding workshops. Furthermore, th

Friction stir welding aluminum plates can shorten the production cycle by 15%~25%, reduce welding variables, and produce no arc light or fume emissions, meeting the environmental protection requirements of shipbuilding workshops.

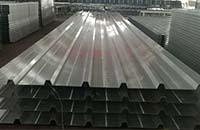

Furthermore, this technology is suitable for the integrated molding requirements of large-size aluminum plate components such as ship decks and bulkheads, improving the overall structural stability of the vessel.

This process also places stringent requirements on shipbuilding aluminum plate production: it requires specialized friction stir welding equipment with a long stroke and high rigidity; and it necessitates professional technicians to adjust welding parameters and monitor quality in real time to ensure that the welding quality of marine grade aluminum sheets meets international shipbuilding standards.

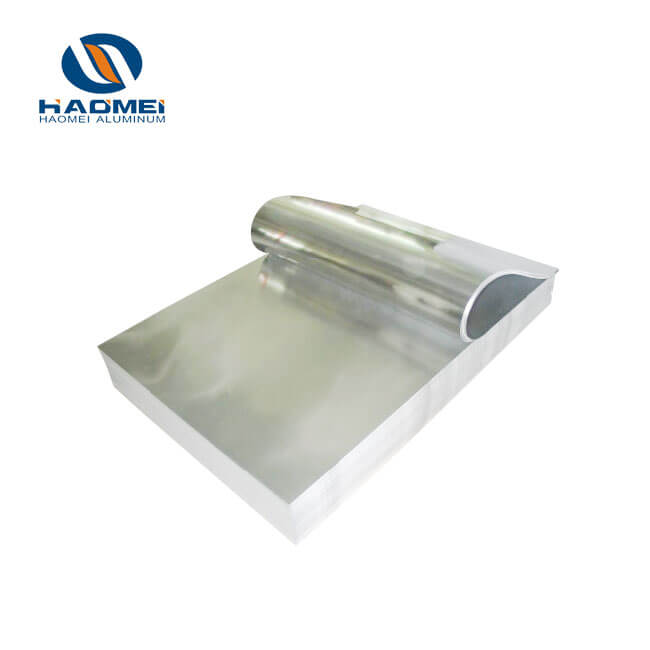

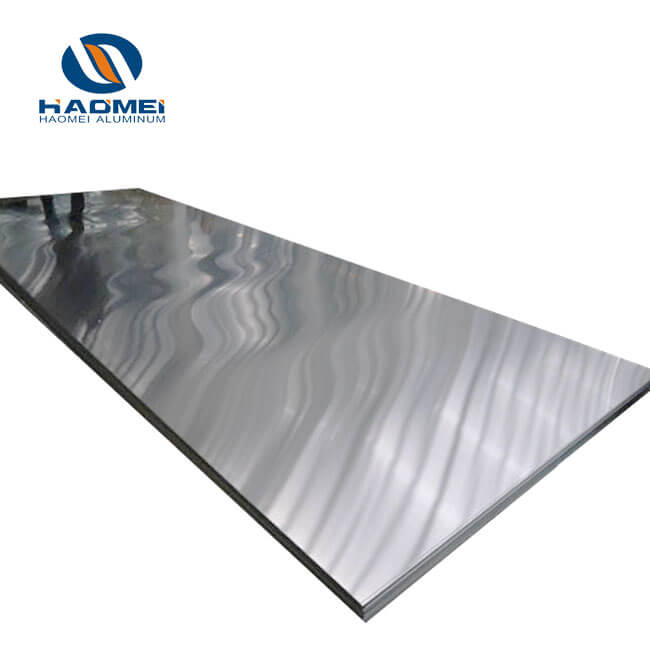

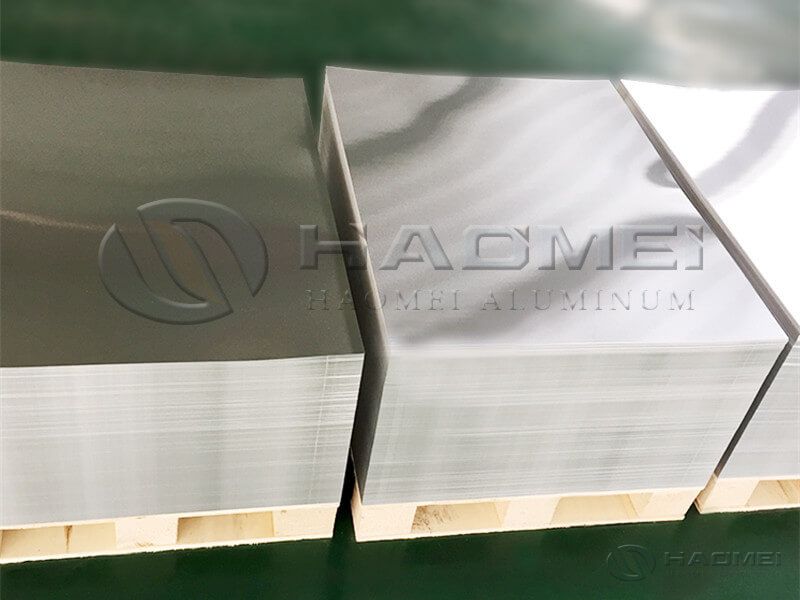

Haomei Aluminum can provide you with such high-quality FSW aluminum plates. This is our FSW aluminum sheet manufacturing process.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China