3003 Aluminum Coil For Insulation Jacketing:Thickness Guide

Learn about 3003 aluminum jacketing coils for thermal insulation: compare polysurlyn vs. kraft paper types, choose the right thickness (0.2–1.0mm) for construction, pipelines, chemical & coastal projects, with corrosion resistance & cost tips.

In thermal insulation projects, 3003 aluminum jacketing coils have become a preferred material in construction, chemical, and pipeline industries due to their excellent rust resistance, good formability, and cost-effectiveness.

As a commonly used rust-resistant aluminum in the aluminum-manganese alloy series, 3003 contains 1.0-1.5% manganese, and its strength is about 20% higher than that of pure aluminum, while retaining excellent processability and corrosion resistance, making it particularly suitable for humid and highly corrosive insulation environments.

The most common 3003 aluminum insulated coils on the market are mainly divided into two types: polysurlyn laminated aluminum coils and kraft paper aluminum coils. Different types and thicknesses of aluminum coils have significantly different applicable scenarios and insulation effects. How to choose? Let me tell you.

1. Polysurlyn coated 3003 aluminum coils

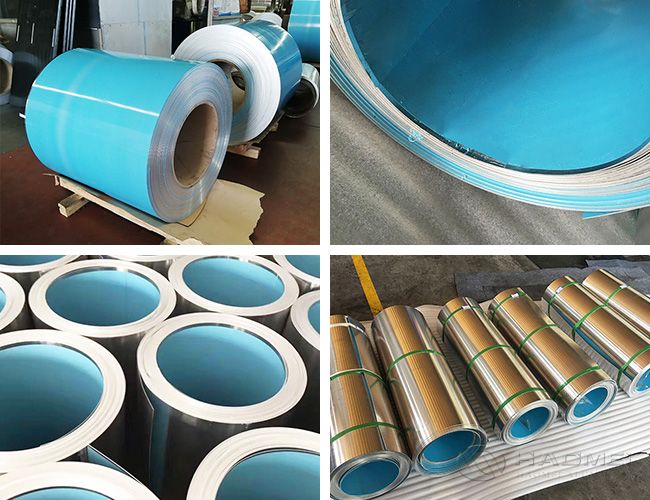

Polysurlyn coated aluminum coils are made by laminating a layer of salin film (a polymer film) onto the surface of 3003 aluminum coils using a heat-applied process. This coating process is technically challenging, and the cost of the salin film itself is even higher than that of the aluminum material, therefore the overall price is significantly higher than that of kraft paper aluminum coils. Its core advantages lie in its exceptional moisture-proof and corrosion-resistant properties.

After a 24-hour immersion test, the film adheres firmly to the aluminum coil, preventing delamination or peeling. Furthermore, the sarin membrane exhibits excellent weather resistance, unaffected by temperature changes, effectively protecting the aluminum coil surface from oxidation and corrosion.

Suitable Scenarios: Ideal for environments with stringent moisture-proof and corrosion-resistant requirements, such as humid coastal areas, chemical plant pipeline insulation, underground engineering insulation, and projects exported to the Middle East and other high-temperature, high-humidity regions. Its service life can reach over 20 years. Additionally, sarin-coated aluminum coils can be further processed into embossed aluminum coils to meet more customized insulation needs.

2. Kraft Paper 3003 Insulated Aluminum Coil

Kraft paper aluminum coils consist of a layer of kraft paper heat-coated onto the surface of a 3003 aluminum coil. A relatively new type of insulated aluminum coil introduced in recent years, it offers better value for money and is one of the most widely used types on the market. Kraft paper is commonly 0.14-0.15mm thick, weighing approximately 0.08kg per square meter. It offers good moisture resistance, meeting the needs of most conventional insulation projects, and its cost is controllable, making it suitable for bulk purchases.

Applicable Scenarios: Conventional building insulation (such as wall and roof insulation), general pipe insulation, cold storage insulation, and projects with limited budgets but requiring basic moisture and corrosion resistance. It should be noted that its moisture and corrosion resistance is slightly inferior to that of aluminum foil membrane rolls, and it is not recommended for use in environments with long-term high humidity and strong corrosion.

Standard Thicknesses

1. Thin (0.2mm-0.3mm): Primarily lightweight and low-cost, suitable for shallow indoor insulation, temporary insulation, or as an auxiliary protective layer for insulation layers, such as temporary indoor pipe insulation and small equipment insulation. Advantages include light weight and easy installation; disadvantages include weak load-bearing capacity, susceptibility to scratches and damage, and unsuitability for outdoor projects or projects exposed to complex environments for extended periods.

2. Medium Thickness (0.4mm-0.6mm): Offers the best value for money, suitable for over 90% of conventional insulation applications, and is currently the most commonly used thickness on the market. Whether coated with saline membrane or kraft paper, this thickness of aluminum coil meets basic moisture-proof, corrosion-proof, and insulation requirements while also possessing a certain load-bearing capacity. It has moderate installation difficulty and can be used for building walls, roof insulation, conventional industrial pipeline insulation, cold storage insulation, etc., balancing practicality and economy.

3. Thick Thickness (0.7mm-1.0mm): Primarily features high strength and wear resistance, suitable for applications with high protection requirements, such as outdoor open-air pipeline insulation, high-altitude equipment insulation, insulation in highly corrosive environments like chemical workshops, and insulation projects requiring resistance to certain external impacts. Thick aluminum coils offer more stable moisture-proof and corrosion-proof performance and a longer service life, but the cost is relatively higher, and installation requires specialized tools, resulting in slightly less flexibility.

How to Precisely Match Thickness

1. 3003 aluminum insulation coil laminated with polysurlyn film: Offers excellent inherent protection, and the thickness can be adjusted according to the degree of environmental corrosion. For highly corrosive environments such as coastal areas or chemical plants, a thickness of 0.6mm-1.0mm is recommended to further enhance durability.

For ordinary humid environments (such as underground garage pipe insulation), a medium thickness of 0.4mm-0.6mm is sufficient; excessive thickness is unnecessary and avoids wasting costs. Additionally, the standard thickness range for salim-coated aluminum coils is 0.2-2.0mm, but custom thicknesses can be made for specific projects.

2. 3003 aluminum coil with kraft paper: Protective performance depends on the kraft paper and the aluminum coil itself. A medium-thickness option is recommended to improve durability. For standard building insulation (walls, roofs), choose 0.4mm-0.6mm; for indoor standard pipe and cold storage insulation, choose 0.3mm-0.5mm. Avoid outdoor use as much as possible. If outdoor use is necessary, a thickness of 0.7mm or more is recommended, with additional waterproofing to prevent moisture damage to the kraft paper.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China