1000 Series Aluminum Alloys: 1050 and 1100

1050 and 1100 aluminium alloy are mainly composed of aluminum and have excellent forming and processing characteristics. What are their other properties and uses? Learn more.

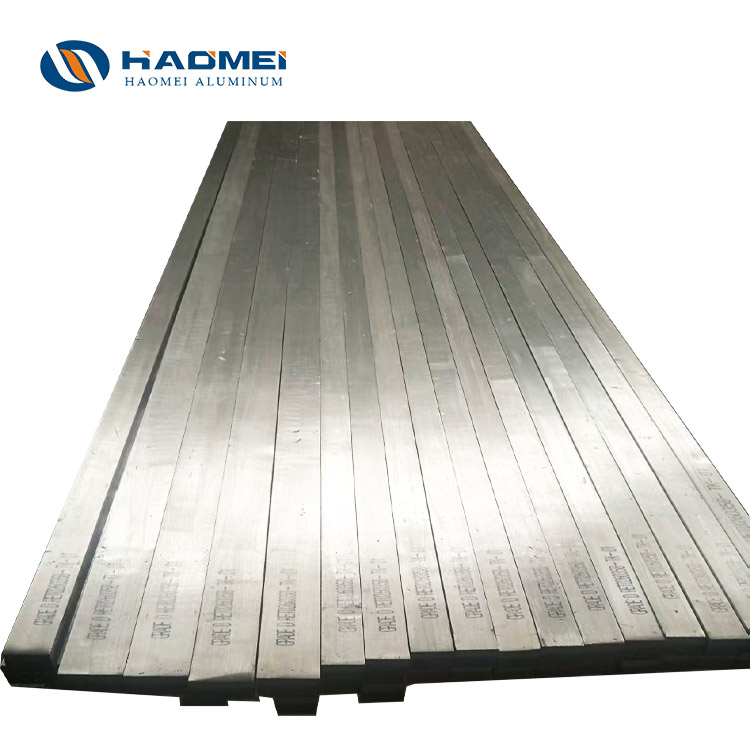

The aluminum content of 1050 aluminum sheet can reach more than 99.5%. 1050 aluminium alloy is formed by adding a small amount of copper elements to pure aluminum. It has excellent forming and processing characteristics, high corrosion resistance, good weldability and conductivity. 1050 aluminum plate generally uses a thickness between 0.5-10mm. 1050 aluminum plate is mainly used for sheet metal processing parts, and the amount of ultra-thick 1050 aluminum plate is very small.

Due to the small consumption amount of 1050 aluminum sheet, users who need 1050 aluminum plate need to choose customization, which takes about 10 days. The customers can also choose 1060 aluminum sheet.

The chemical composition of the two is quite close, and the difference in aluminum content is only 0.01%. Although the two are completely consistent in processing performance, the content is different after all. Haomei Aluminum support free sample for testing.

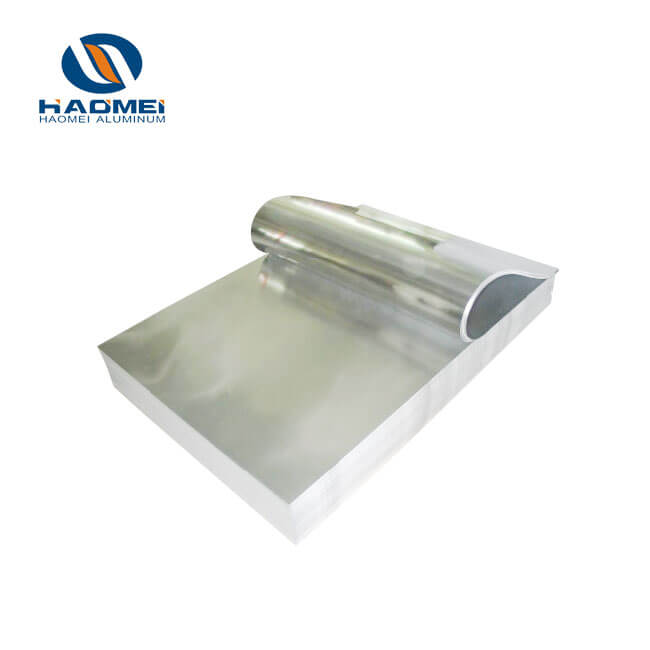

1100 pure aluminum alloy is mainly composed of aluminum and contains very small amounts of other elements. The strength of 1100 aluminum alloy is relatively low and is generally used in some applications that do not require high strength. Its yield strength is usually 80 MPa (megapascals) and its tensile strength is about 110 MPa.

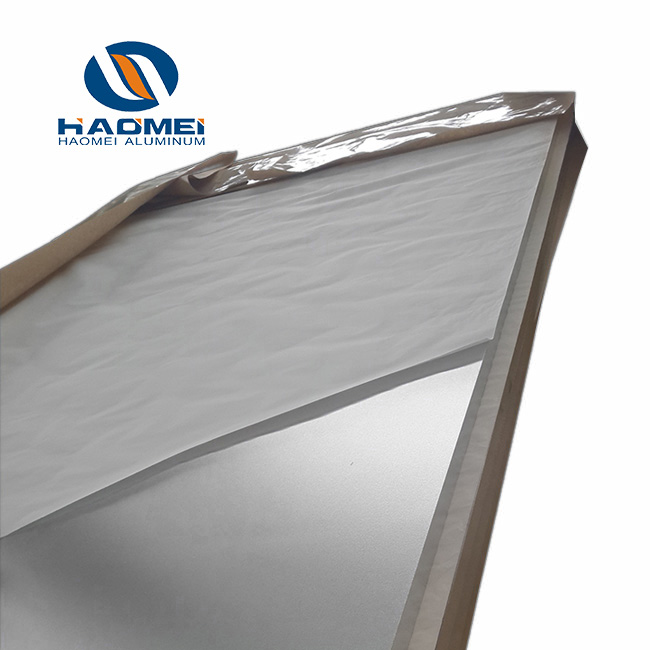

1100 aluminum sheet is usually delivered in O temper, that is, the original state without heat treatment. 1100-O aluminum sheet has good plasticity and machinability, and is suitable for various forming and processing operations. It can also be cold processed or heat treated, such as H12, H14, H16 and other states, to obtain a certain strength and hardness.

1100 aluminum sheet features

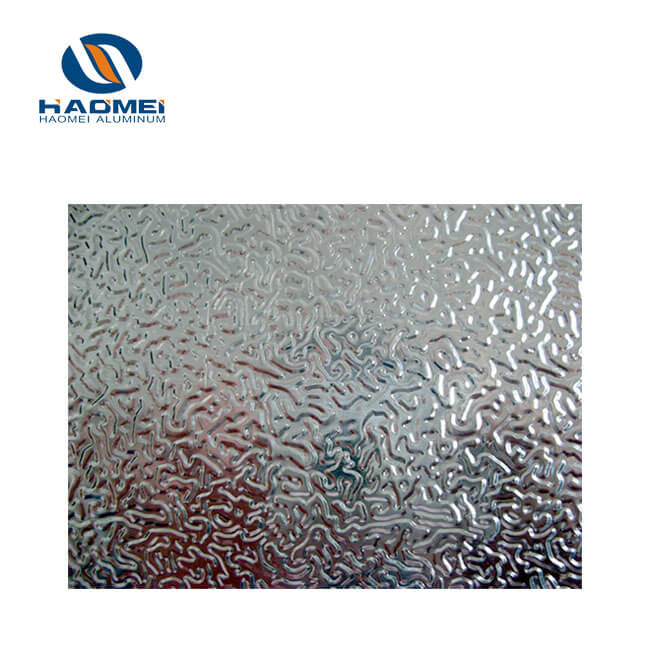

High ductility: 1100 aluminum plate has high ductility, which can be easily stretched and bent.

Good conductivity: 1100 aluminum plate has good electrical conductivity and is a common material in the field of electronics and electrical appliances.

Good corrosion resistance: 1100 aluminum plate has good corrosion resistance and can be used for a long time in corrosive environments such as acid and alkali.

Good processing performance: 1100 aluminum plate has excellent processing performance and can be processed by drilling, cutting, stamping and other processes.

Application of 1100 aluminum sheet

Heat sink is a device specially used to dissipate heat for heat-prone electronic components in electrical appliances. It can be made of aluminum alloy, brass, bronze and other materials. During use, a layer of thermal conductive silicone grease is usually applied on the contact surface between the electronic components and the heat sink, which is more conducive to heat dissipation. Different materials have different thermal conductivity and different prices. Overall, aluminum heat sink has a high cost-effectiveness and can be made of 1100 aluminium alloy.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China