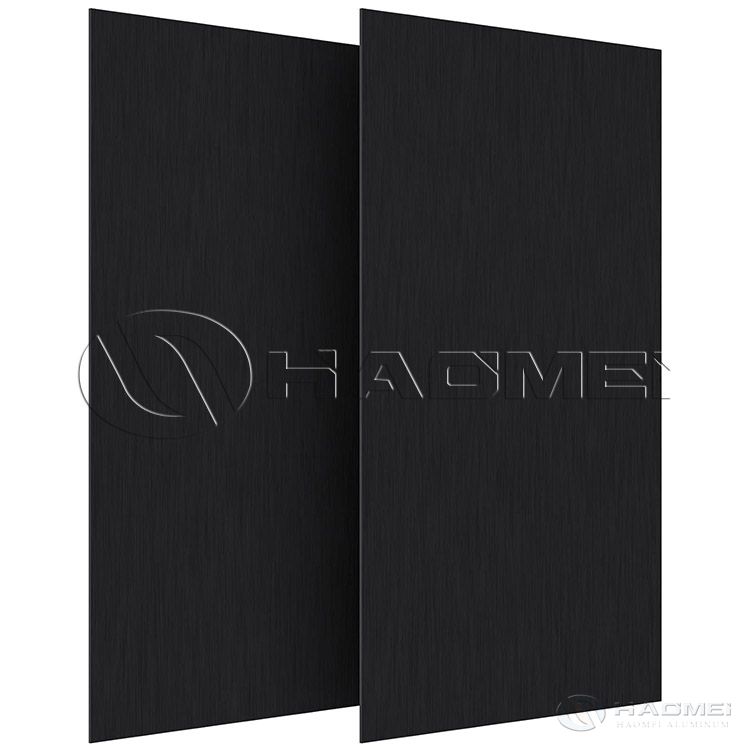

What Is A Black Anodized Aluminum Sheet

A black anodized aluminum sheet is actually filling the anodized surface with black pigment. There are usually two types of anodizing: standard anodizing and hard anodizing. Learn more.

Anodizing is a surface treatment process that uses nonferrous metals such as aluminum, magnesium, and titanium as anodes for electrolysis in an acidic electrolyte to form a dense oxide film on the surface of the material to resist corrosion, improve wear resistance and decoration effect.

The anodized film is usually transparent and has a porous structure at the micro level. The diameter of these pores is 100Å-300Å (1Å=0.1nm). In fact, there are an astonishing 50-70 billion pores per cubic centimeter. Understanding these pores, we can easily understand color anodizing.

For example, if every hole in the oxide film is filled with red dye, red anodization will occur, forming a colored surface that will remain until the oxide film itself wears away. In the same way, other color dyes can form corresponding color anodization. Therefore, a black anodized aluminum sheet is actually filling the anodized surface with black pigment.

Types of anodizing

Anodizing is divided into standard anodizing and hard anodizing. Standard anodizing is completed in a sulfuric acid solution. The thickness of the oxide layer is 5um-30um, and the hardness is usually less than 200HV. Standard anodizing can be colored, such as red, green, blue, etc., to produce various color decorative effects.

Hard anodizing can be achieved by electrolysis using a mixed solution of sulfuric acid and oxalic acid at a higher concentration and lower temperature (0-10°C). The thickness of the oxide layer is 25um-250um. The coating is gray to black and non-porous. The hardness usually reaches 500-900HV, which can enhance the wear resistance of the aluminum alloy surface. The polishing anodized aluminum can be this kind.

Hard anodizing is performed at a lower temperature, is more expensive, and has higher hardness. However, it is generally not distinguishable by the naked eye and can be distinguished through testing or processing.

Not all aluminum alloys can be anodized. The 5xxx, 6xxx and 7xxx series aluminum alloys respond well to hard anodizing, while the 2xxx aluminum alloys and other alloys, including cast aluminum alloys with high copper and silicon content, respond poorly to anodizing.

Applications of anodizing aluminum sheet

1. Personal electronics, like smartphones, tablets.

2. Decorative colorful accessories like carabiners, metal pens, flashlights, etc. Sometimes, we use mirror anodized aluminum.

3. Bicycle parts.

4. Aluminum aircraft parts

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China