Different Types of Anodized Aluminum Material

Anodized aluminum material is a material made by placing pure aluminum or aluminum alloy in an electrolyte solution and forming an oxide film on its surface through electrolysis. This oxide film is not a simple "covering layer," but a "

Anodized aluminum material is a material made by placing pure aluminum or aluminum alloy in an electrolyte solution and forming an oxide film on its surface through electrolysis. This oxide film is not a simple "covering layer," but a "protective layer" tightly bonded to the substrate. Its thickness is typically between 5-20 micrometers.

It not only isolates the aluminum substrate from air and moisture corrosion but also allows for the application of rich colors and textures through dyeing and sealing processes. Compared to ordinary aluminum, its hardness is increased by 3-5 times, and its wear resistance and weather resistance have also achieved a qualitative leap, which is the core reason for its widespread use.

Types

1. Mirror anodized aluminum

This represents the "high-gloss" finish in surface treatment. Through special polishing and anodizing processes, the aluminum sheet surface achieves a high gloss, resembling a mirror, with a reflectivity exceeding 80%. The production process involves multiple precision polishing steps to remove minor surface imperfections, followed by anodizing to form a uniform oxide film, ensuring a long-lasting mirror effect.

Its biggest advantage is its strong visual impact, creating a high-end, luxurious atmosphere. It is commonly used in high-end home appliance panels (such as high-end TV back panels and refrigerator doors), luxury car interiors, and decorative mirrored walls in shopping malls.

However, mirror-finish anodized aluminum sheets require extremely high-precision manufacturing processes, resulting in relatively high costs. Furthermore, scratches from hard objects should be avoided during use to prevent affecting the mirror effect.

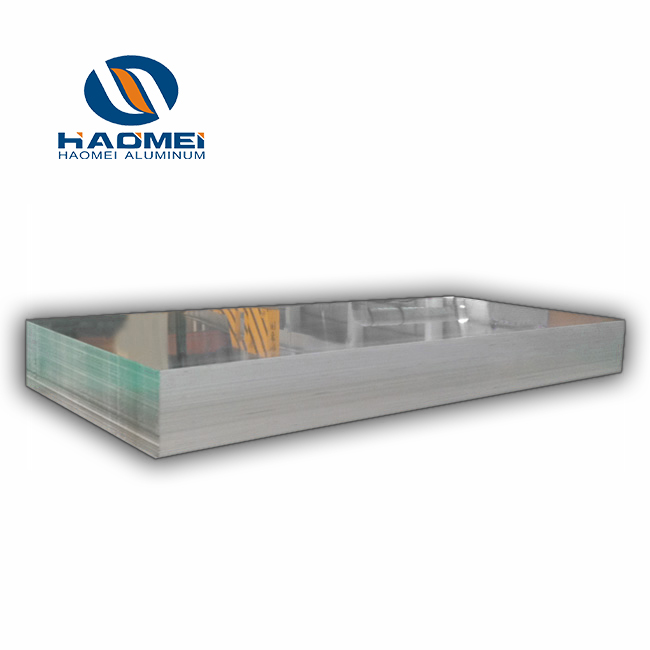

2. Standard anodized aluminum sheets

"Standard" here does not refer to mediocre performance, but rather specifically to the basic type without any special surface texture treatment. Its surface exhibits a uniform matte or semi-matte texture, with rich and consistent color, making it the most widely used type.

The production process is relatively mature, requiring only conventional dyeing and sealing, resulting in moderate costs and a balance between aesthetics and practicality. It's commonly found in furniture trim, kitchenware surfaces, and ordinary appliance casings, becoming a market mainstream due to its stable performance and affordable price.

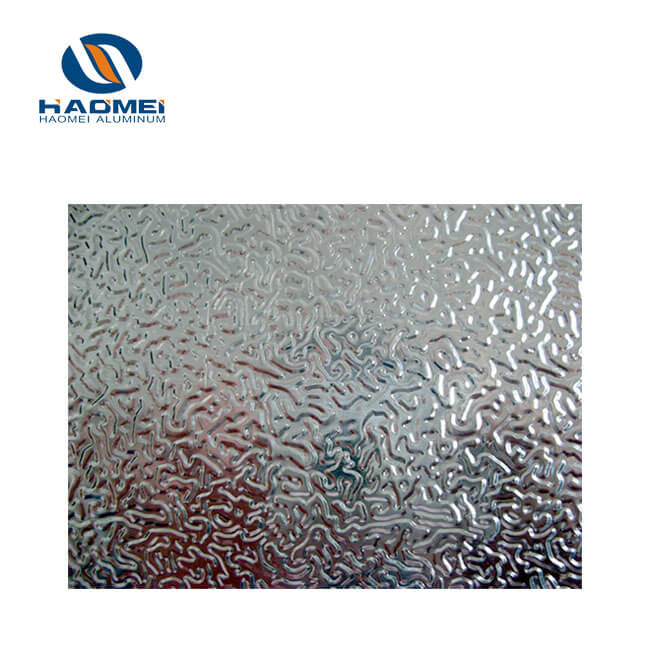

3. Brushed anodized aluminum sheets

Parallel filamentous textures are formed on the aluminum surface through mechanical friction, followed by anodizing to ensure a tight bond between the texture and the oxide film, resulting in a delicate linear texture. Depending on the brushing direction, it can be categorized into straight brushes, random brushes, spiral brushes, etc., with different textures creating minimalist, industrial, or sophisticated visual effects.

Brushing not only enhances the appearance but also effectively conceals minor scratches from use, increasing its practicality. It's widely used in mobile phone frames, laptop casings, furniture armrests, elevator panels, etc., making it a popular choice that balances aesthetics and durability.

4. Sandblasted anodized aluminum sheets

High-pressure jetting is used to impact the aluminum surface with fine abrasive materials (such as quartz sand and alumina sand), creating a uniformly rough surface, followed by anodizing. Its surface exhibits a delicate frosted texture, a warm and smooth feel, and is non-reflective, creating a low-key and understated atmosphere.

The oxide film after sandblasting has stronger adhesion and excellent wear resistance, making it suitable for interior decorative panels, medical device housings, and instrument surfaces, especially in environments with strict requirements for reflectivity.

Different Forms

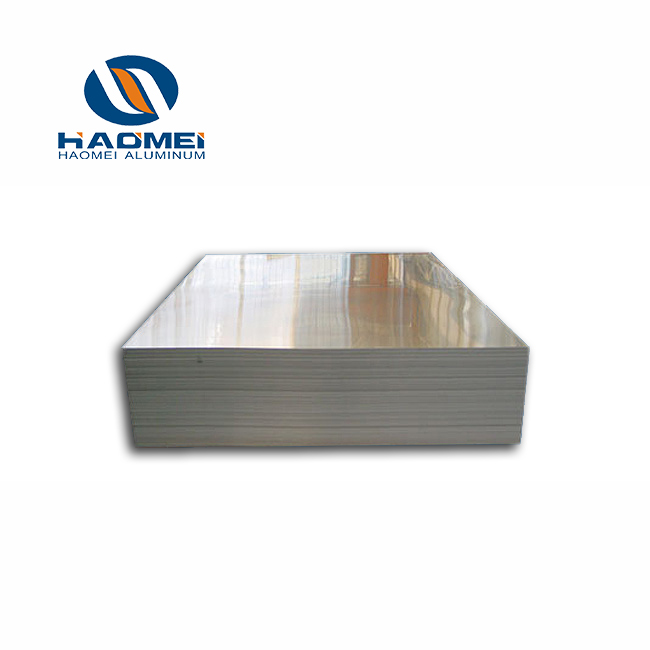

1. Anodized Aluminum Sheets

Anodized aluminum sheets are made by cutting anodized aluminum material into fixed-size plates. The thickness typically ranges from 0.2 mm (thin sheets) to 20 mm (thick sheets), and sizes can be customized (such as the common 1220mm × 2440mm standard sheet or special specifications). Its core advantage lies in its "ready-to-use" convenience, eliminating the need for complex subsequent uncoiling and cutting processes, making it suitable for small to medium batch customization or the production of irregularly shaped parts.

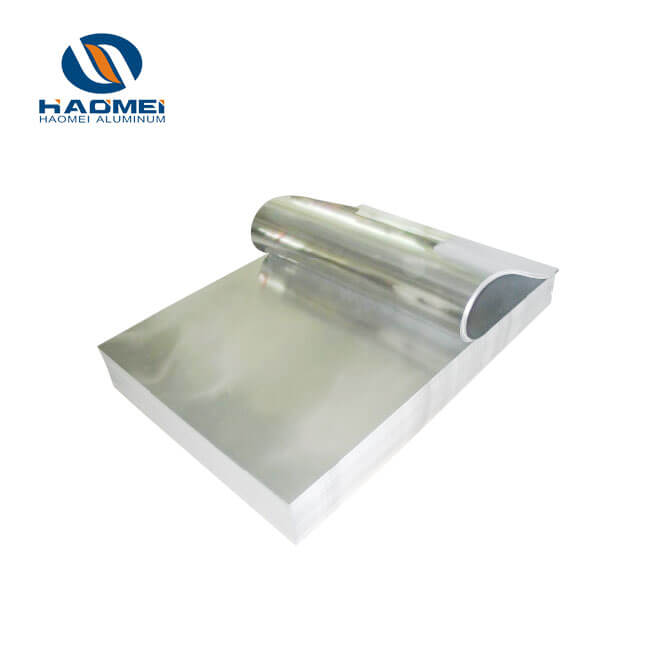

2. Anodized Aluminum Coils

Anodized aluminum coils are made by continuously anodizing aluminum substrates and then storing them in coils. Lengths can reach tens to hundreds of meters, and thicknesses are mostly concentrated between 0.1-1.2 mm. They offer significant advantages in "continuous supply and batch processing."

The production process uses a continuous production line, from substrate rolling and anodizing to dyeing and sealing, with uninterrupted operation throughout. This not only improves production efficiency but also ensures the consistency of material surface properties, making it particularly suitable for large-scale, standardized product production.

It's worth noting that both aluminum sheets and coils can be further refined based on surface treatment processes (such as mirror finish, brushed finish, and sandblasting) to create a combination of "form + texture." For example, mirror-finish anodized aluminum sheets are suitable for high-end decoration, while brushed anodized aluminum coils can be supplied in bulk to electronic equipment manufacturers, achieving a balance between performance and efficiency. Haomei Aluminum is one of the big anodized aluminum sheet suppliers. Welcome to inquire what you need from us.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China