Aluminium 3000 Series: 3003 and 3004

The main grades of aluminum 3000 series are 3003 and 3004. What are their differences? They are different in chemical composition, physical properties, price differences,etc. Learn more.

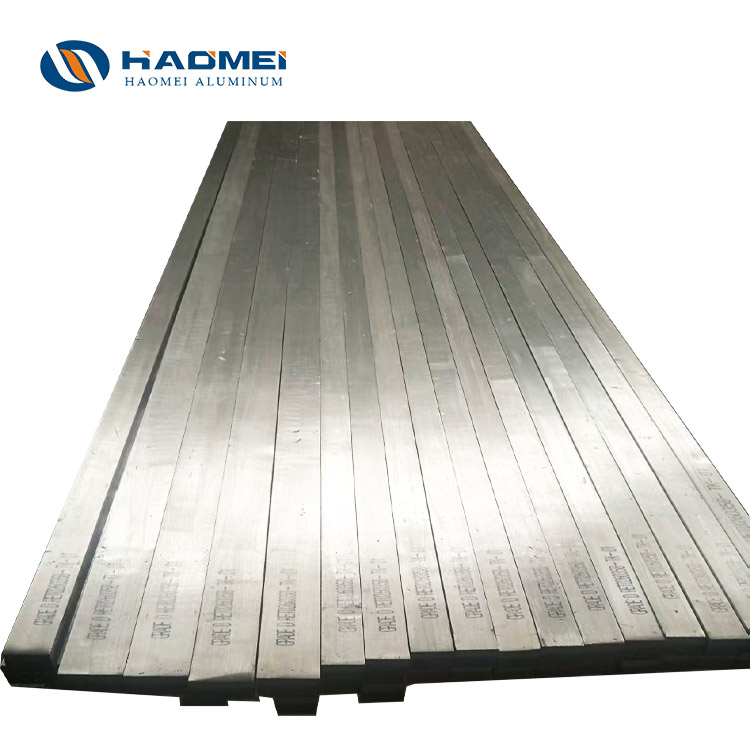

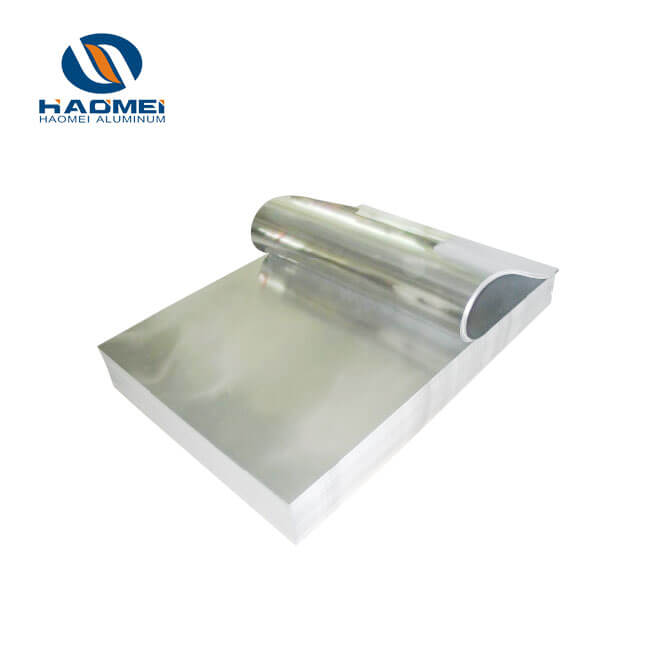

Aluminium 3000 series is an aluminum alloy with manganese as the main alloying element. It cannot be strengthened by heat treatment. It has excellent corrosion resistance, excellent welding performance and excellent plasticity, but its strength is low. In fact, its strength can be enhanced through cold work hardening. Its main grades are A3003 material and 3004.

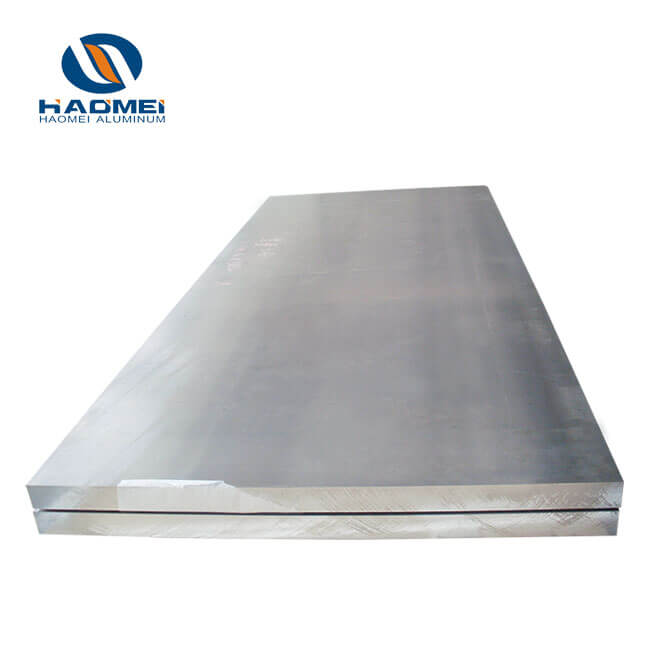

3004 has higher strength than 3003 aluminum plate, which has excellent formability, good corrosion resistance, good weldability, poor machinability,etc. It is mainly used for the parts that require higher strength than 3003 alloy, such as chemical product storage devices, thin plate processing parts, building baffles, cable ducts, sewer pipes and various lighting parts.

AA3004 aluminum-magnesium-manganese alloy is widely recognized as a roofing and exterior wall material with a design life of more than 50 years due to its moderate structural strength, weather resistance, stain resistance, and easy bending and welding processing. What are the differences between 3004 and 3003?

1. Chemical composition

The chemical composition of 3003 and 3004 is slightly different. The main component of 3003 alloy is aluminum, accounting for more than 98%, and it also contains small amounts of copper, silicon and other elements. The aluminum content in 3004 alloy is also more than 98%, but it also contains 0.8% magnesium and 0.3% silicon.

2. Physical properties

Aluminum alloys 3003 and 3004 also differ in physical properties. 3003 alloy has a high thermal expansion coefficient and a low melting point, as well as good plasticity and corrosion resistance. The thermal expansion coefficient of 3004 alloy is slightly lower than that of 3003, but its melting point is slightly higher. It also has good wear resistance and corrosion resistance.

3. Application scope

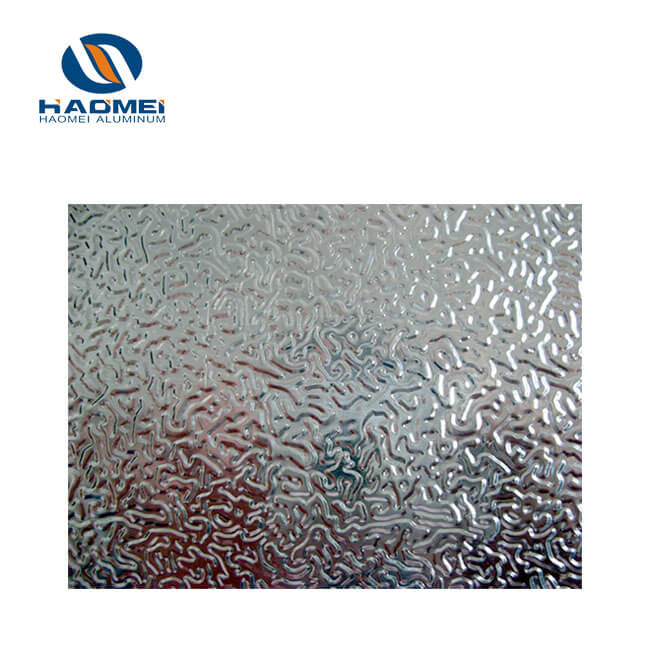

Due to the different physical and chemical properties of aluminum alloys 3003 and 3004, there are also differences in their practical applications. 3003 alloy is usually used to manufacture some light products such as containers, pipes, and fuel tanks. The 3004 alloy is more suitable for manufacturing products that require higher corrosion resistance and wear resistance, such as automobile shells and decorative panels.

4. Price difference

The prices of aluminum alloy 3003 and 3004 are also different. Since 3004 alloy contains a higher proportion of magnesium and silicon elements, its manufacturing cost is relatively high, so the price is slightly higher than 3003 alloy.

5. Processing Difficulty

Aluminum alloys 3003 and 3004 also differ in the processing difficulty. Because 3003 alloy like 3003 aluminum diamond plate has good plasticity and toughness, it is easier to handle during processing and forming. The 3004 alloy is relatively brittle, requiring more care when handling, and is relatively difficult to process.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China