5052 Aluminum Coil Wholesale

An 800-word guide for bulk buyers on 5052 aluminum coil wholesale: specs, tempers, applications, pricing drivers, QC, packaging, and how to order.

What makes 5052 coil different (and when to use it)

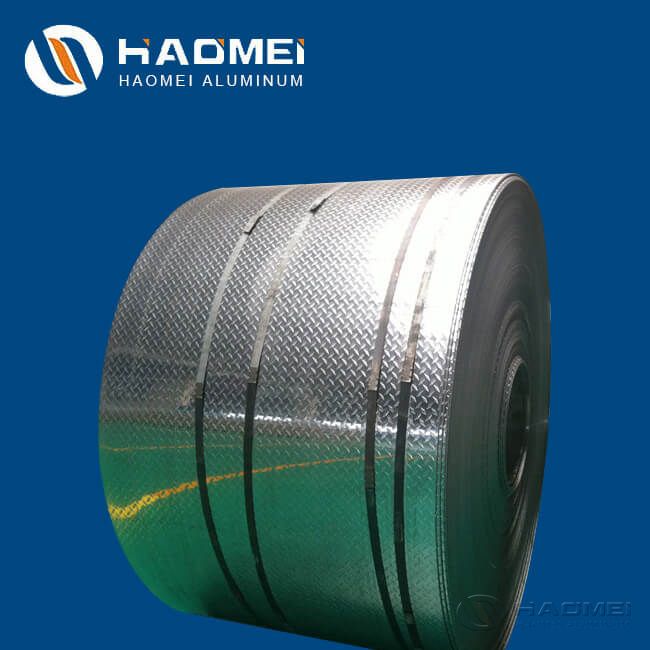

5052 is an Al-Mg alloy widely used for sheet and coil in environments where moisture, salt spray, and daily wear matter. Compared with 3003, it generally offers higher strength and better fatigue performance, making it popular for transportation panels, appliance housings, tread plate, and general metal forming that needs durability.

Its also a practical choice for buyers who need consistent bending and stamping. 5052 in softer tempers can handle tighter radii with fewer edge cracks, while harder tempers improve dent resistance. For many OEMs, 5052 is the default coil when 1100 is too soft and 6061 is unnecessary.

Wholesale specifications you should confirm

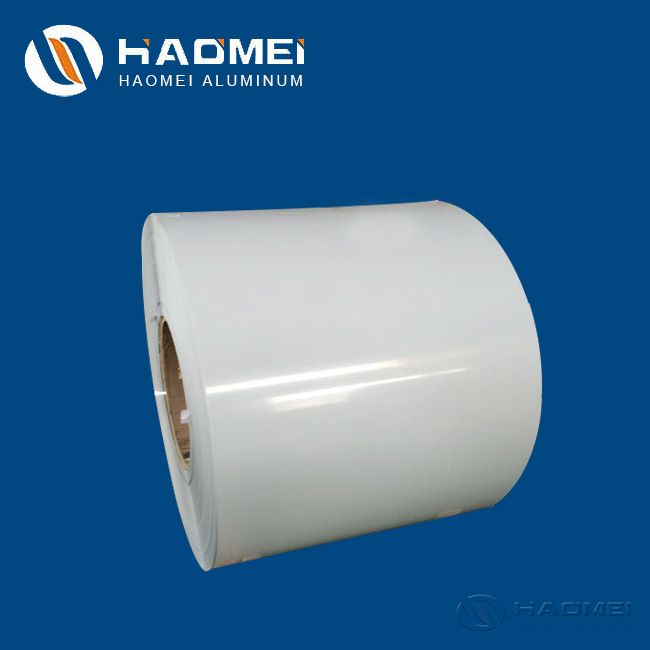

For 5052 aluminum coil wholesale purchases, confusion usually comes from incomplete specifications. To avoid mismatches, confirm alloy, temper, thickness, width, coil ID/OD limits, and surface requirements (mill finish, one-side protective film, or specific roughness targets). Also define edge condition (mill edge or slit edge) and acceptable camber.

Below is a buyer-friendly checklist you can send to suppliers during RFQ. It reduces back-and-forth and helps you compare quotes on the same basis.

| Item to Specify | Typical Options | Why It Matters for Bulk Orders |

|---|---|---|

| Temper | O, H32, H34 (common) | Affects bendability, springback, and strength |

| Thickness | e.g., 0.36.0 mm | Determines forming feasibility and scrap risk |

| Width | slit to size or jumbo | Impacts yield for your blank layout |

| Coil ID | 508/610 mm (common) | Must fit decoiler and line mandrel |

| Surface | mill finish / film | Prevents scratches and downstream rejection |

| Edge | slit edge / mill edge | Influences safety, crack initiation, appearance |

| Standards | ASTM B209 / EN / GB | Ensures consistent chemistry & tolerances |

Temper selection: the simplest way to avoid forming problems

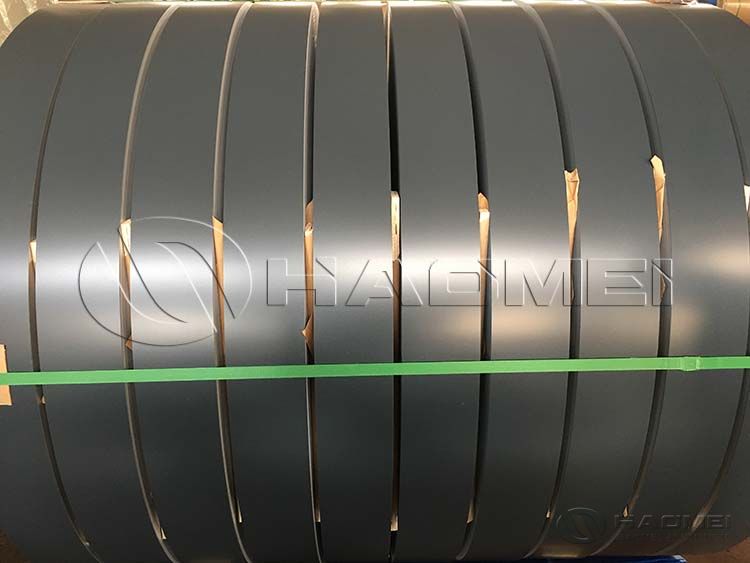

Most bulk buyers narrow quickly to O, H32, and H34. 5052-O is annealed and best for deep drawing or tight bends, but its softer and may show handling marks. H32 is strain-hardened and stabilized, offering a strong balance for general fabrication. H34 is harder, better for panels needing higher dent resistance, but it can increase cracking risk in tight radii.

If youre running high-speed stamping, ask your supplier to align mechanical properties to your die design, not just the minimum standard. In wholesale quantities, consistent coil-to-coil performance reduces downtime and die wearoften worth more than saving a few dollars per ton.

Pricing, MOQ, and lead time: what drives your landed cost

5052 coil pricing typically tracks aluminum ingot indexes plus conversion (rolling, slitting, finishing), packaging, and logistics. Conversion rises with tight thickness tolerances, extra-flatness requirements, film lamination, special testing, and small-lot slitting. For bulk buyers, wider master coils can reduce conversion cost, while multiple slit widths can increase it.

Lead time depends on base coil availability, finishing capacity, and export booking cycles. If your project is schedule-sensitive, confirm whether the supplier is quoting ex-stock, rolling plan, or made-to-order. Also clarify incoterms, payment terms, and claim windows for transit damage.

When comparing suppliers, review their core product offering. If you also source general aluminum coil for other alloys or projects, consolidating specifications and packaging standards can simplify inbound QC and warehousing.

5) Quality control and packaging for wholesale shipments

Quality issues on coil usually appear as surface scratches, edge wave, thickness variation, and inconsistent temper. Ask for mill test certificates, coil photos before shipment, and (if critical) third-party inspection for thickness, width, flatness, and surface. For appearance-driven parts, define acceptable defects and sampling rules in the PO.

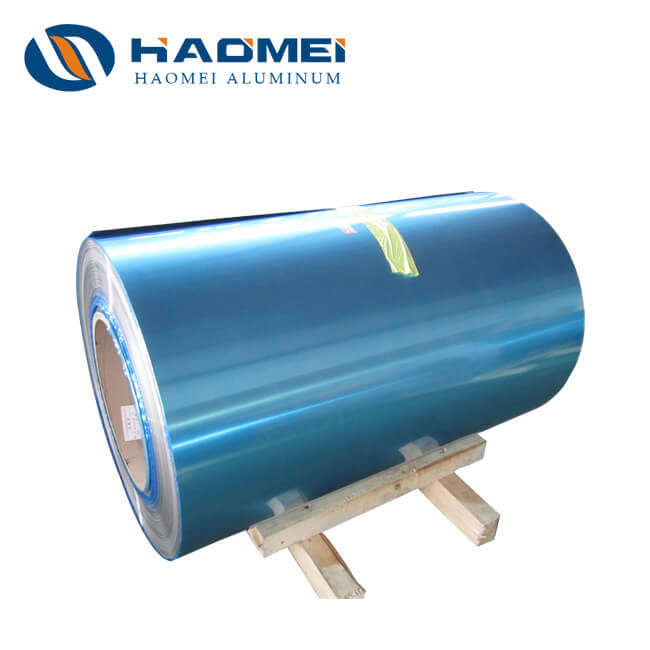

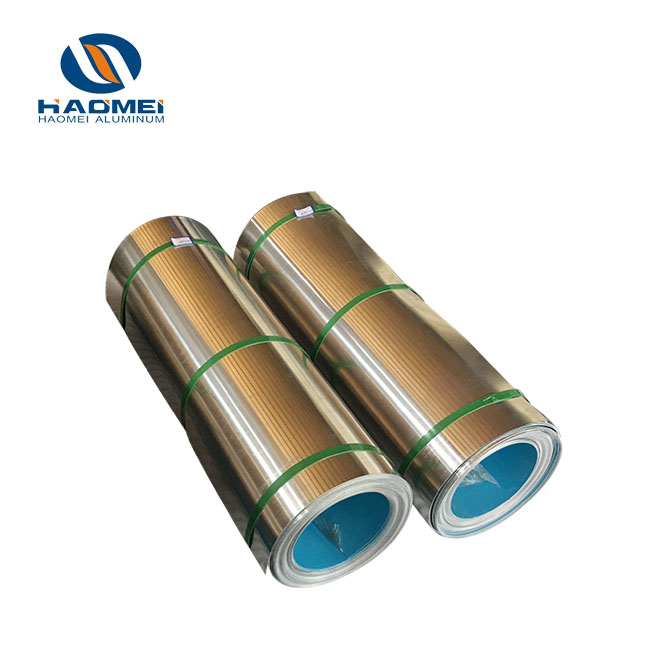

Packaging matters just as much as metallurgy in wholesale buying. Specify seaworthy packing, moisture barrier, corner protection, pallet base requirements, and maximum coil weight per skid. For long voyages or humid destinations, vapor inhibitors and laminated wrap reduce oxidation and water stain risk.

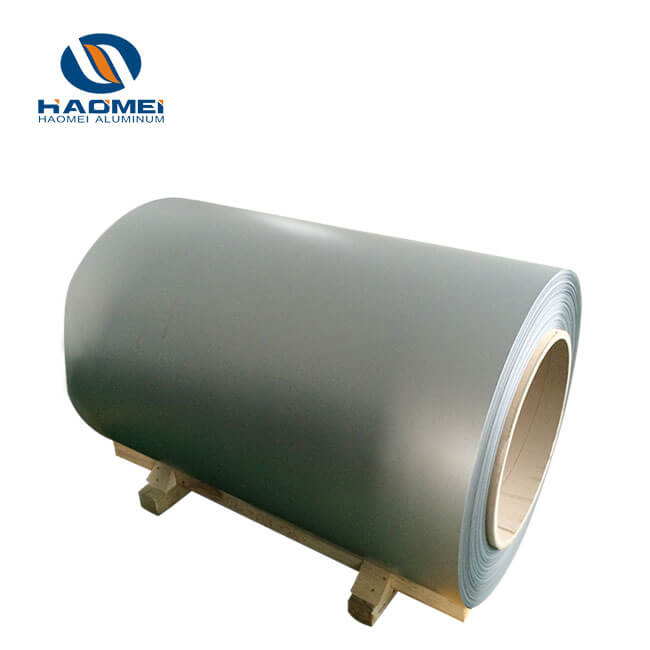

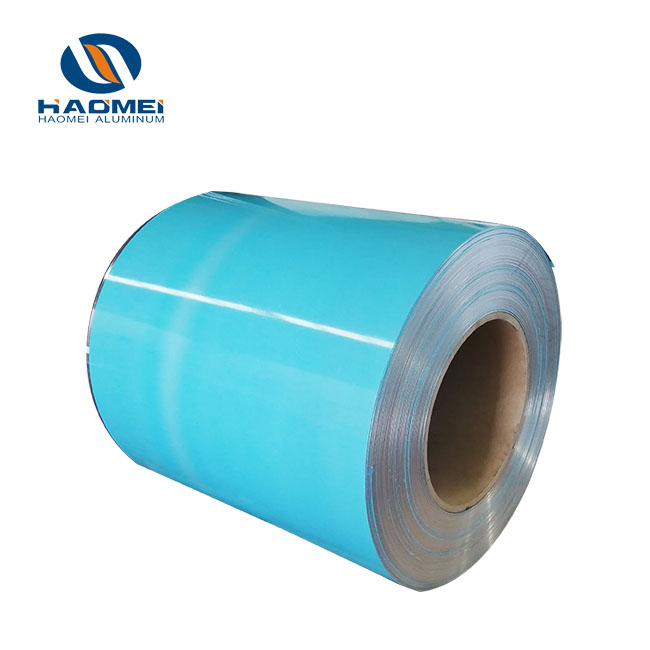

If your application requires coated material rather than mill finish, align coating system and performance expectations early. Many buyers pair base alloy sourcing with a finishing route such as PVDF coated aluminum coil for exterior-grade durability and color retention.

Quick buying FAQ (for RFQ clarity)

What thickness range is common for 5052 coil? Many projects fall between 0.53.0 mm, but broader ranges are possible depending on mill capacity.

Is 5052 suitable for marine use? It has strong corrosion resistance and is widely used near salt environments; confirm temper and protective requirements based on your design.

What should I request with the order? Alloy/temper, dimensions, standard, surface/film, edge condition, coil ID/OD, max coil weight, packaging, MTC, and inspection plan.

If you share your end use (forming method, target bend radius, thickness/width, and annual tonnage), suppliers can recommend the most stable temper, slit plan, and packaging to minimize scrap and protect your landed cost.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China