Which Kind of Aluminum Sheets Are Used as Solar Reflector

In the solar energy utilization system, solar reflectors play a key role, which can effectively improve the efficiency of solar energy collection. Aluminum plates, with their excellent performance, have become an ideal material for solar reflectors.

In the solar energy utilization system, solar reflectors play a key role, which can effectively improve the efficiency of solar energy collection. Aluminum plates, with their excellent performance, have become an ideal material for solar reflectors.

1. Requirements for aluminum plates for solar reflectors

High reflectivity: This is the most critical point. High reflectivity can reflect more sunlight to solar energy collection devices,thereby improving the overall efficiency of the solar energy system. The diffuse reflectivity of ordinary industrial pure aluminum plates is about 0.4, and the total reflectivity is 0.7; while the diffuse reflector made of embossed aluminum plates can reach a diffuse reflectivity of 0.6 (AM2), and the total reflectivity is increased to 0.78.

Good corrosion resistance: Solar reflectors are usually installed outdoors and are subjected to wind, sun, rain and various harsh environments for a long time. Aluminum plates need to have good corrosion resistance to ensure long-term stable reflective performance. If the surface of the aluminum plate corrodes and oxidizes, the total reflectivity will be reduced, affecting the efficiency of the solar system.

Suitable mechanical properties: The aluminum plate must have a certain strength and toughness. During installation and use, it can withstand a certain external force and is not prone to deformation, cracking and other conditions. At the same time, it must also have good processing performance to facilitate processing into reflectors of different shapes and specifications.

Stability: Under different temperature and humidity conditions, the physical and chemical properties of the aluminum plate should remain stable to avoid fluctuations in reflectivity or degradation of material properties due to environmental changes.

2. Types of aluminum plates suitable for solar reflectors

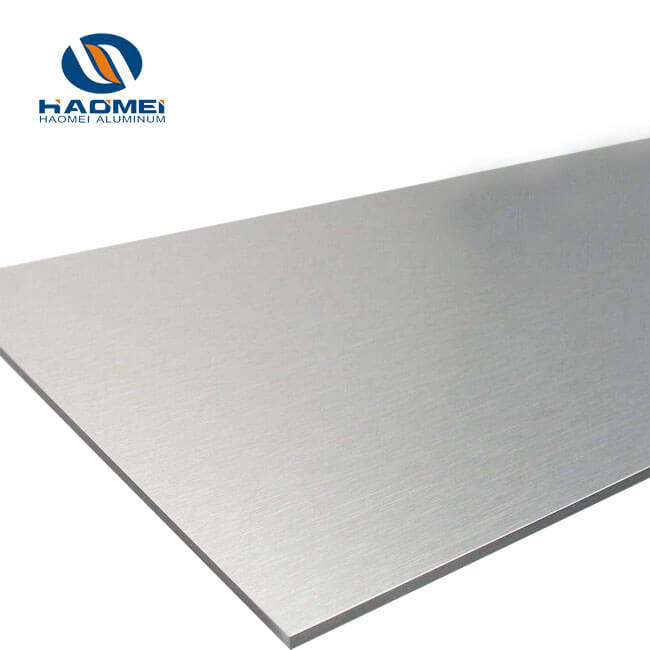

Mirror aluminum plates

The mirror polished aluminum sheet is an aluminum plate that has been processed by rolling, grinding and other processes to make the surface of the plate present a mirror effect. Its reflectivity is extremely high, reaching 86% - 95%, which can significantly improve the reflection efficiency of solar reflectors to light and concentrate more solar energy on the heat collection device.

In addition, after the mirror aluminum plate is surface treated with fluorocarbon spraying, polyester paint or epoxy resin paint, it can resist strong ultraviolet radiation, maintain color stability for a long time, and has a long service life.

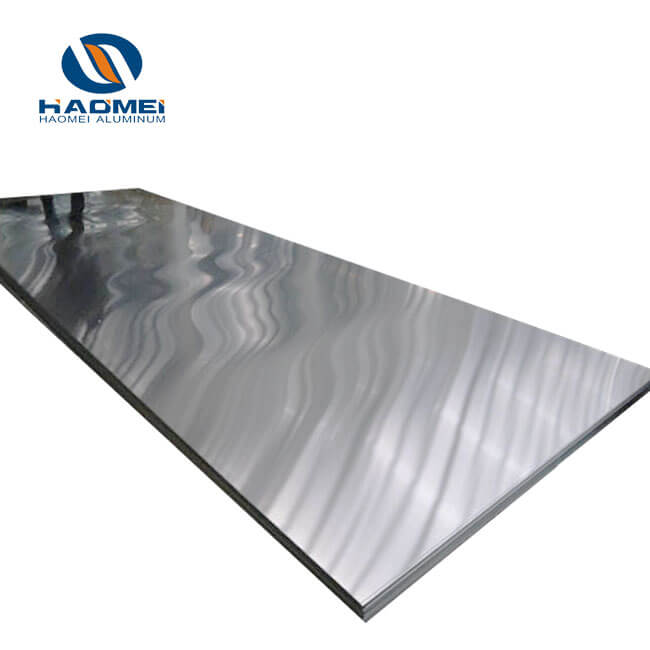

Embossed aluminum sheet

The embossed aluminum sheet is an aluminum sheet with an uneven embossed pattern on the surface after rolling. Compared with ordinary aluminum sheets, its diffuse reflection performance is better. The diffuse reflectivity of the solar diffuse reflector made of embossed aluminum sheet is 50% higher than that of ordinary industrial pure aluminum sheet, and the total reflectivity is increased by 11%.

PVDF coated aluminum sheet

PVDF aluminum composite panel is coated with a layer of PVDF coating on the surface of the aluminum sheet, and the coating thickness is usually ≥25 micron. This coating gives the aluminum sheet excellent weather resistance, corrosion resistance and chemical resistance, and can be used for a long time in harsh environments without fading or corrosion. At the same time, the color-coated aluminum sheet is rich and varied in color, which can meet the appearance requirements of different projects.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China