What Is Offset Printing Plate Thickness

The common offset printing plate thickness is 0.14 (0.15) , 0.27 (0.30)mm and 0.23(0.25)mm. 0.40 mm is a unconventional thickness. What are the production methods to produce aluminum substrate for offset plates?

The common offset printing plate thickness is 0.14 (0.15) , 0.27 (0.30)mm and 0.23(0.25)mm. 0.40 mm is a unconventional thickness. The aluminum substrate thickness is 0.13-0.3 mm. Aluminum sheet is the core basic material of PS/CTP plates. Commonly used alloy grades are 1050, 1052, 1060 and 1070, and the mass fractions of aluminum are ≥99.50%, ≥99.52%, ≥99.60%, ≥99.70%

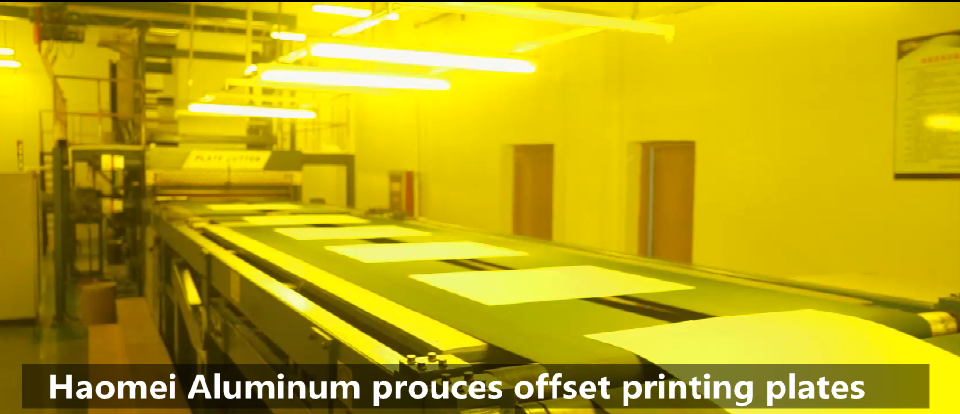

Since offset plates has high requirements on the surface quality of aluminum sheets, the aluminum sheet production process is very special. There are three types of blank supply methods for aluminum sheet substrate.

1. The continuous cast-rolling method is to feed the molten and purified aluminum liquid into the "roll gap" formed between two rotating rolls, and through the forced cooling, crystallization and deformation of the two rolls, aluminum blanks with a thickness of 6-8 mm is obtained.

During the casting and rolling process, the molten aluminum is crystallized by the rapid cooling of the rolls in the narrow gap between the two rolls, and the solidified billet is rolled and deformed to a certain extent by the rolls at the same time, and the internal structure of the obtained cast-rolled sheet belongs to semi-cast structure, featuring strong crystal structure.

2. Continue casting direct Rolling is to inject the molten aluminum melt through the launder and nozzle into the synchronously running upper and lower steel belts or caterpillars and side stoppers after heat preservation and quenching and tempering treatment.

The 19 mm thick strip billet is continuously cast, and then coiled into coils after on-line hot rolling (or hot rolling). The liquid aluminum is crystallized in the twin-belt casting machine, and the cooling rate of the continuous casting machine is as high as 50-70 ℃/ s, which makes it easier to obtain a smaller grain size, the crystal structure of the billet is dense and fine, the dendrite spacing is small, and the solid solubility of alloying elements is large, which improves the structure and performance of the product to a certain extent.

3. The ingot hot rolling method is to cast the molten aluminum into a slab after refining and purification, and then pass through the milling machine to remove the oxidation inclusions on the surface of the slab. It is then heated and rolled to a few millimeters thick hot-rolled coil at a temperature higher than the recrystallization temperature.

Due to the large volume of the hot-rolled slab, the internal structure has undergone multiple recovery and recrystallization during the plastic deformation process, which significantly improves internal organization and reduces finished product defects.

Although the products produced by the continuous cast-rolling method have problems such as poor internal quality, surface segregation, difficult production, and unstable quality, it has the advantages of less investment, high efficiency, and low cost. Therefore, we usually use this method to produce aluminum sheets for PS plate, but it will not used to make CTP plate.

The continuous casting and direct rolling is short-process production process, featuring energy saving and emission reduction. This method saves the energy consumption of aluminum ingot cutting, surface milling and aluminum ingot preheating, the lower limit of the thickness of the hot-rolled strip is 1 mm, and part of the cold-rolling passes can be saved.

What’s more, the yield of continuous casting and direct rolling is 94% to 96%, which is unmatched by other methods. However, the surface quality and performance of its products are slightly worse than those of ingot hot rolling. It can satisfy the requirements of PS plate. We still use ingot hot rolling method to produce high quality aluminum sheet for thermal plates.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China