Effect of Trace Alloy Elements on Electrolytic Oxidation Quality of PS Plate

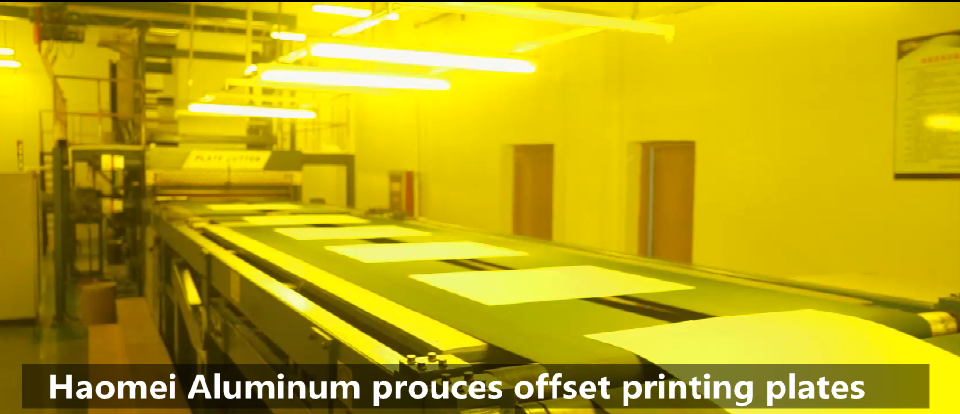

The trace alloy elements in aluminum base plate has Si, Fe, Cu, Mn,etc. has a certain effect o the electrolytic oxidation quality of positive and negative PS plate. What’s the influence? Learn more.

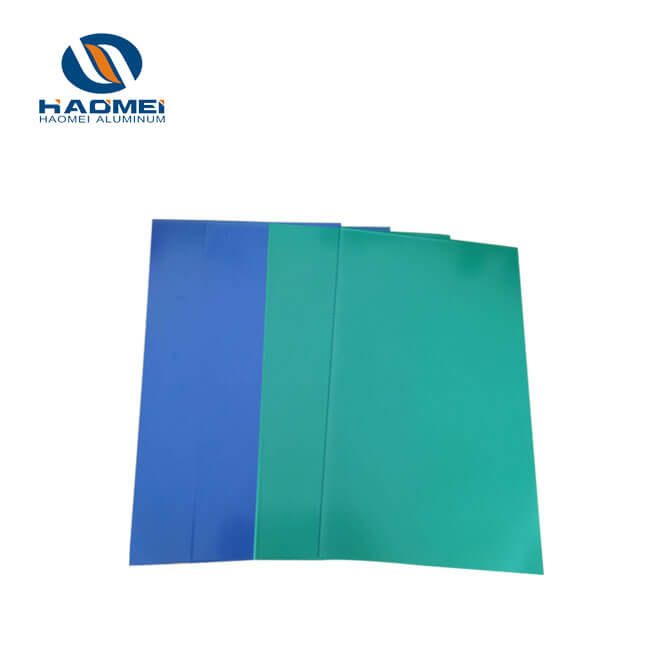

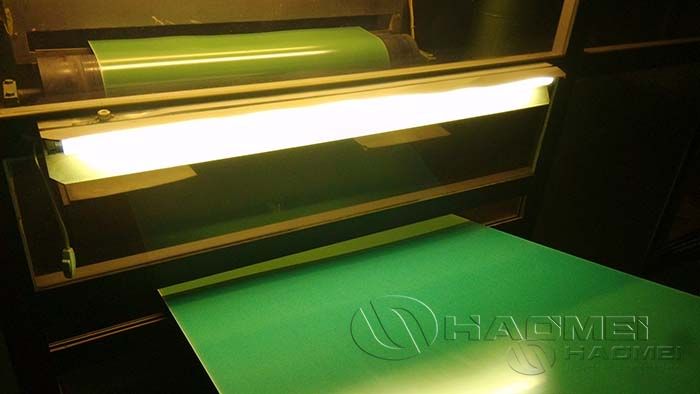

PS plate is a traditional plate for offset printing,which has two types: positive PS plate and negative PS plate. It is made of industrial pure aluminum with over 99.5% of aluminum content. The trace alloy element and impurities are Si, Fe, Cu, Mn, Mg, Zn, Ti, Ni. The above-mentioned trace elements in the aluminum base plate has a certain influence on the electrolytic oxidation quality.

The content of silicon is generally controlled between 0.05% and 0.35%, and more than 0.35% is detrimental to the uniformity of the roughened surface of the aluminum plate. In addition, it is better to limit the content of monomer silicon in the cold-rolled sheet to less than 0.012% for it is easy to cause oxide film defects.

The iron element has the effect of making the electrolytic roughening uniform. The content of iron in aluminum base plate is usually between 0.05% and 0.5%. When the iron content is less than 0.05%, the electrolytic roughing effect is poor while if the content is more than 0.5%, it will make electrolytic roughened surface uneven.

Copper has a certain solid solution strengthening effect, and can accelerate the corrosion rate, which is beneficial to electrolysis. It is better to control the copper content below 0.05%. If it exceeds 0.05%, the recesses generated during the electrochemical treatment is easily coarse.

Manganese contributes to refine the structure of aluminum base plate and has a significant effect on the recrystallization process of aluminum and its alloys. The Manganese content of aluminum base plate for negative PS plate is usually below 0.4%.

Magnesium tends to suppress the coarsening of the recrystallized grain, simplify the ingot heating process and contributes to has better electrolytic effect.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China