What Is PS Plate

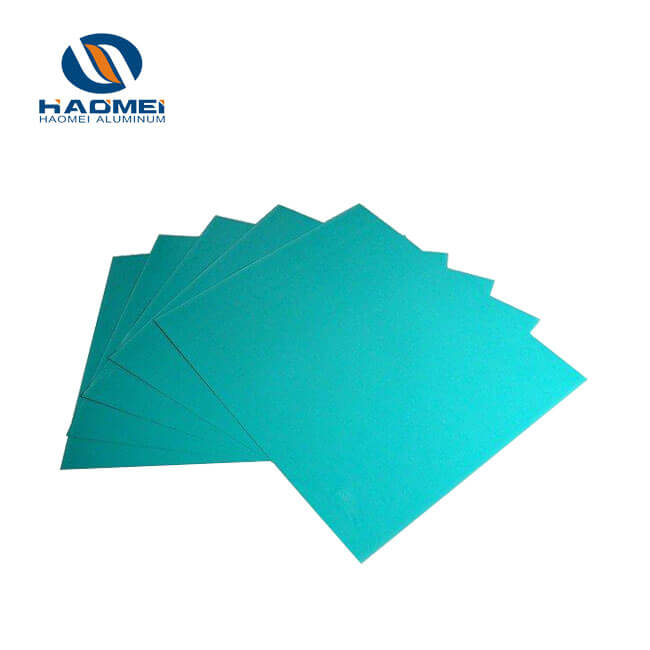

PS plate or offset printing is a kind of conventional plates for use with film based production processes, manufactured for superior performance. We also have CTP plates for you.

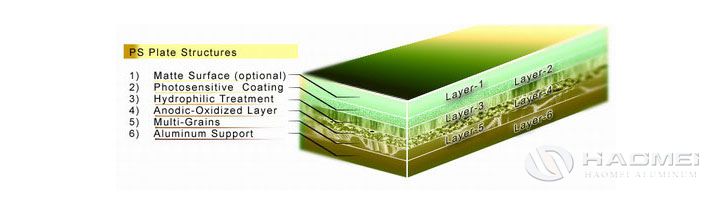

Haomei PS plate, with durable and strong oxidized surface, excels other manufacturer in terms of largely increased printing capacity, corrosion resistance and run length.

Advantages of Positive PS Plate

Excellent resolving ability. Our photosensitive coating is made up of top photographic emulsion and resin, which is of great alkaline resistance, stability and high sensitivity.

Superior pressrun ability. Anodic-oxidation layer is of the superior durability, good chemical resistance for long runs and great printing reliability.

Sustainable Ink-water Equilibrium. We use diazo phtosensitive resin matched with aluminum oxide film, speeding up the ink-water equilibrium procedure.

Our PS plate is compatible with most positive plate developers and processors on the market.

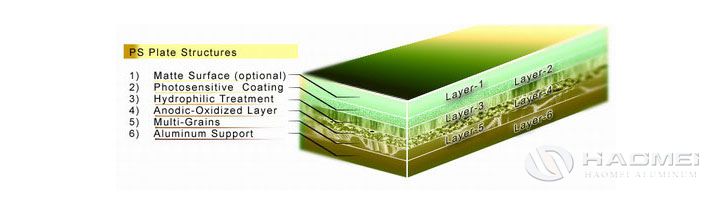

Multiple layer grain structure not only ensures the printing quality, but also ensures its long-term stability.

Technical Parameters for Conventional Positive PS plate

Plate Type | conventional positive PS plate |

Application | Advanced Sophisticated Colour Printing |

Substrate | Electro-chemically grained & anodized lithographic aluminium |

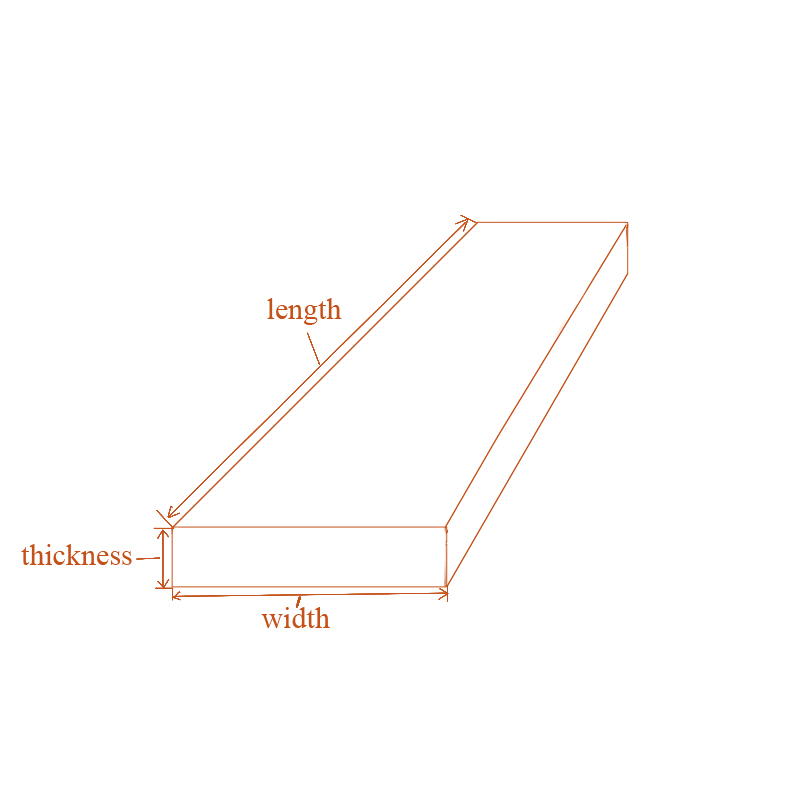

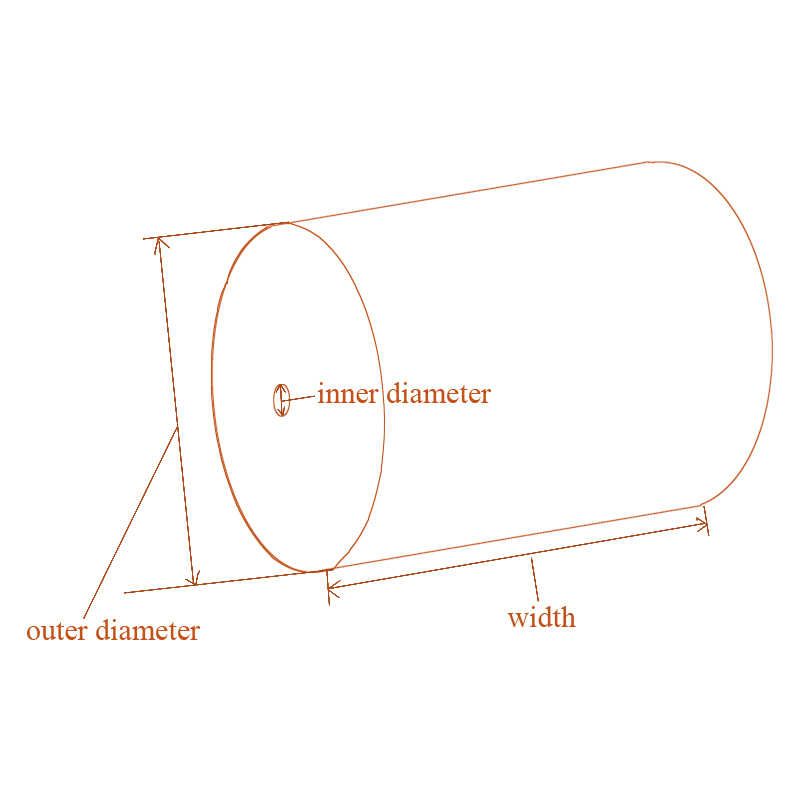

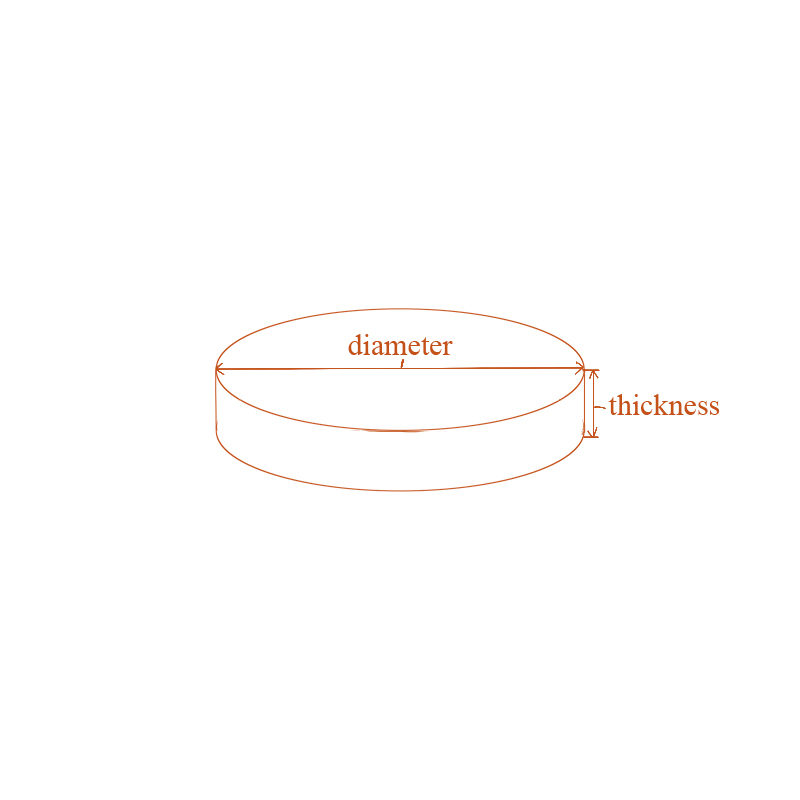

Gauge | 0.15-0.3mm |

Size | Maximum width 1500mm |

Alloy Temper | 1050 1060 H18 |

Spectral Sensitivity | 360-450nm UV light & 400-410nm UV laser |

Exposure | 30 seconds, approx. 20 pulses (3kw Lodine-Gallium lamp, from 1m, UGRA PCW82 control strip, the third section un-inking) *Duration varies with its printing conditions and materials. |

Resolution | 1-98% @ 200 lpi |

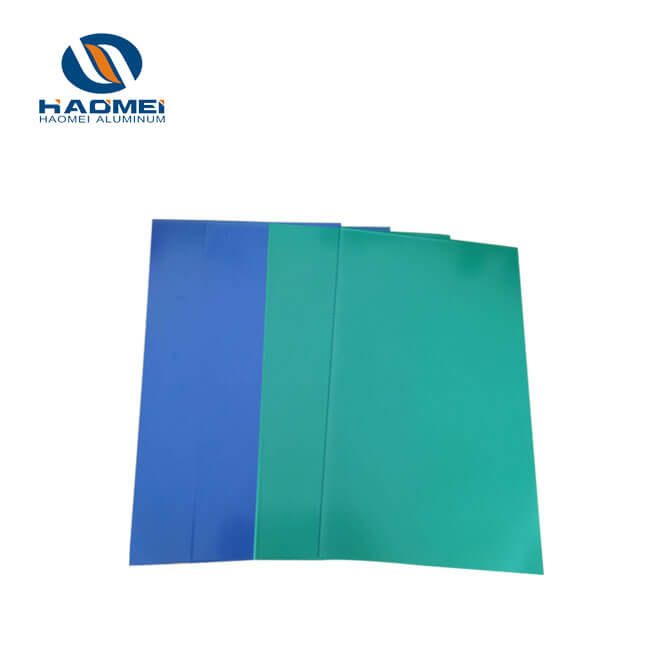

Image Color | green |

Accredited Platesetters | 320-450nm |

Accredited Developers | Positive PS Plate developer |

Processing | Developer temperature: 23±2°c |

Run length Shelf Life | 50 000-100 000 (Actual run length may vary according to press, ink and paper conditions) |

Storage | It's recommended that plates should be stored under 25±5℃, with humidity less than 40% |

Shelf Life | 18 months |

Other name | PS plate,Presensitized Offset Plates,Positive PS Plate |