What Are Main Types of Offset Printing Plates

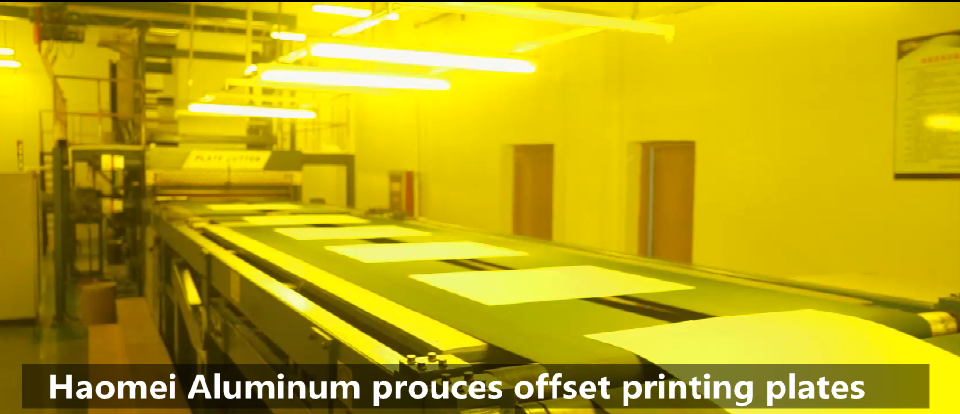

The main types of offset printing are mainly CTP plates. In addition to the thermal CTP plate, violet laser CTP plate is also a popular type. It has a higher printing durability. Learn more.

Offset printing is a very commonly used printing technology. The offset press transfers the ink image from the printing plate to the rubber blanket. It is transferred from the rubber blanket to the printing surface. In offset printing technology, a flat image carrier is used. Compared with other printing technologies, offset printing is the cheapest of all printing technologies.

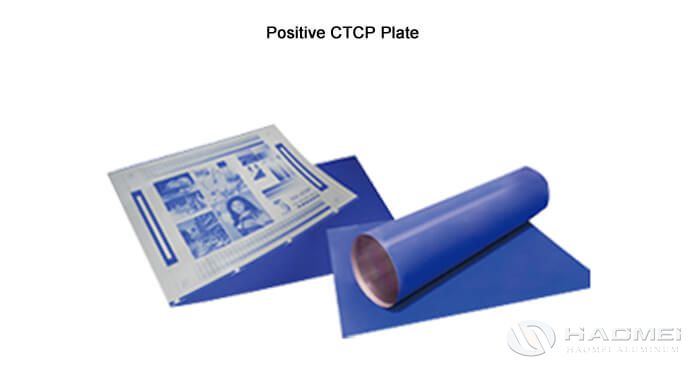

The main types of offset printing are CTP plates. Computer-to-plate (CTP) is an imaging technology used in modern printing processes. China is the largest production region, with a share of about 68%, followed by Europe and Japan, with shares of 16% and 7% respectively.

Asia-Pacific is the world's largest digital offset printing plate market, accounting for about 63%, followed by Europe and North America, accounting for 18% and 14% respectively. In terms of product type, thermal CTP plate is the largest segment, accounting for about 73% of the share.

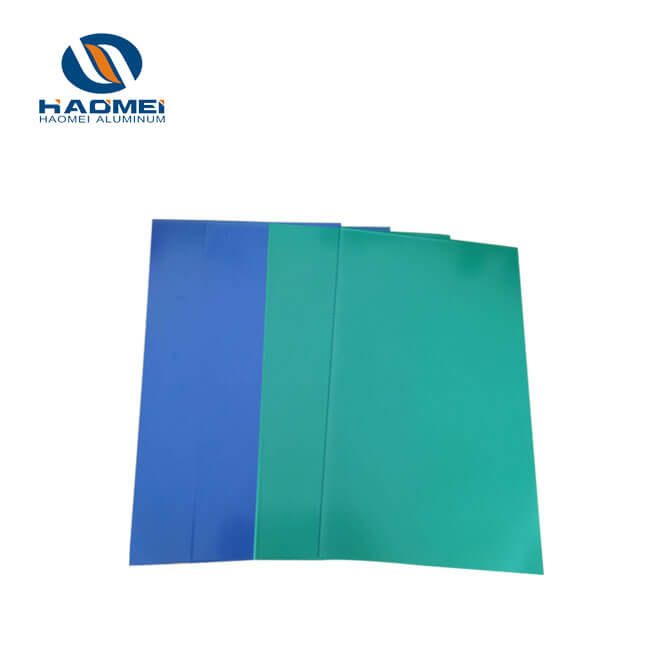

The violet laser CTP belong to the visible light series and are divided into silver salt plates and photopolymer plates. Silver salt plates contain a silver halide layer, which forms a metallic silver image area after diffusion on the plate surface. This layer is sensitive to light and has fast exposure. Only 5mW laser is needed. Its printing durability is about 350,000 prints, and no baking is required.

However, the developer contains harmful ingredients and needs to be treated for environmental protection; the photopolymer plate only contains photopolymers, and the waste liquid does not contain harmful substances. After baking the plate, it can reach 1 million prints. The application cost of violet laser CTP is mainly reflected in the replacement cost of the laser, the washing cost of the plate, the maintenance cost of the equipment and other aspects.

When the laser head power reaches more than 150mW, it can achieve process free like thermal CTP technology. This is another big impact on thermal CTP, because only thermal CTP plate could achieve process-free. Now the market has already started to supply processing-free violet laser CTP plates.

Violet laser chemical-free plate is an environmentally friendly product that helps us achieve green printing. The amount of printing plate glue used is very low and the waste liquid generated is very small. The waste liquid it generates is less than 1/20 of traditional film platemaking and 1/10 of traditional direct platemaking plates, and it saves the cost of developer.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China