Two Types of Digital Offset Printing Plates

Offset printing plates are mainly divided into two types, namely PS plates and CTP plates. What are their developing direction? PS plate mainly includes positive and negative ps plate. How about CTP plate? Learn more.

At present, the printing market has developed a variety of printing methods such as offset printing, gravure printing, flexo printing, letterpress printing, digital printing, and screen printing. As the most important information transmission medium for printing, digital offset printing plates are continuously expanding in production and sales.

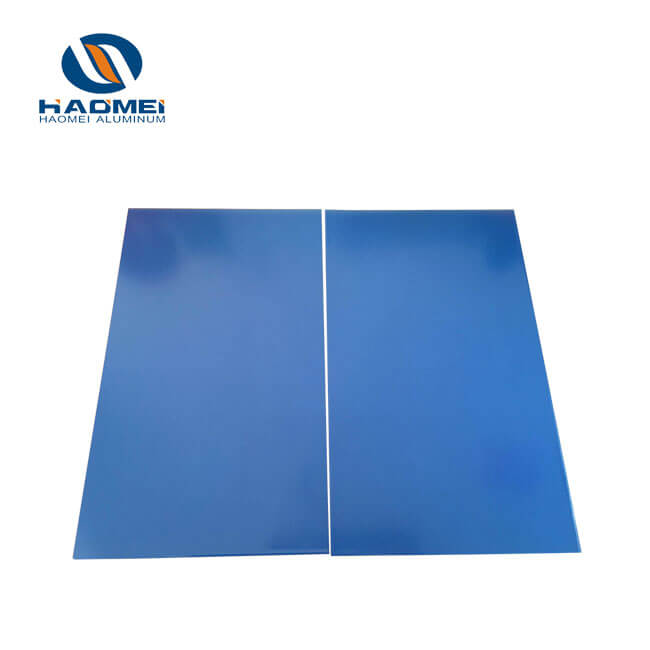

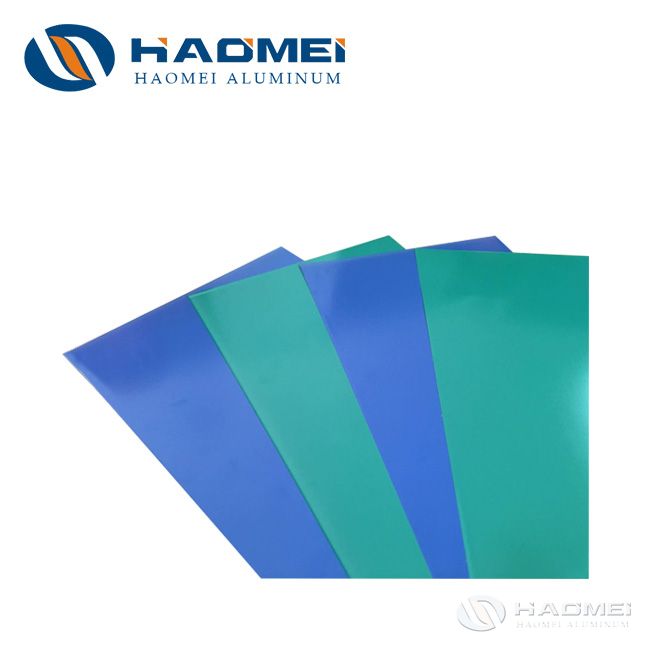

Offset printing is a common printing technique in which an inked image is transferred from a printing plate to a blanket and then onto a printing surface. Specifically, the printing plate must be able to transfer the image to paper or other substrates. Printed plates are usually made from thin metal sheets of aluminum. From the perspective of technical categories, currently offset printing plates are mainly divided into two types, namely PS plates and CTP plates.

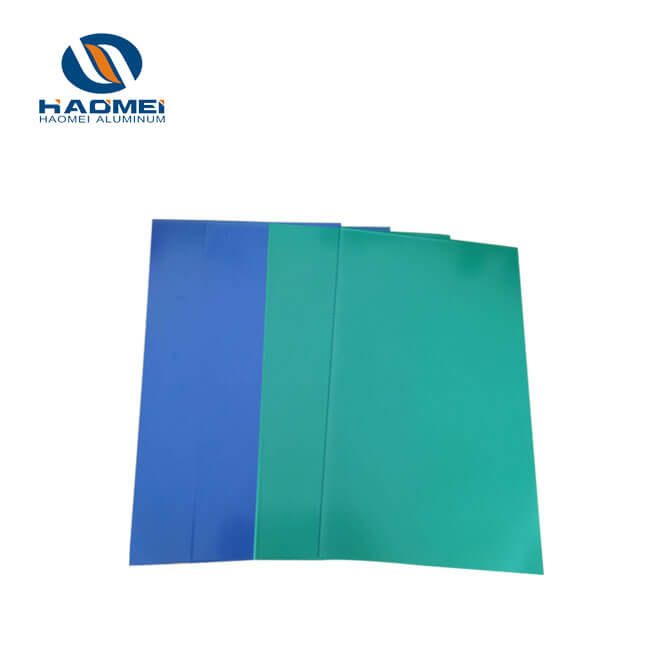

PS plates mainly includes PS plates represented by diazonaphthoquinone resin photosensitizers, and negative PS plate represented by azide photosensitizers. The emergence of CTP plates greatly simplifies the plate-making process, effectively improves work efficiency, and ensures the authentic quality of printed products, so it has been widely used. CTP plate technology can be further subdivided into thermal CTP plate, UV-CTP plate and other technologies.

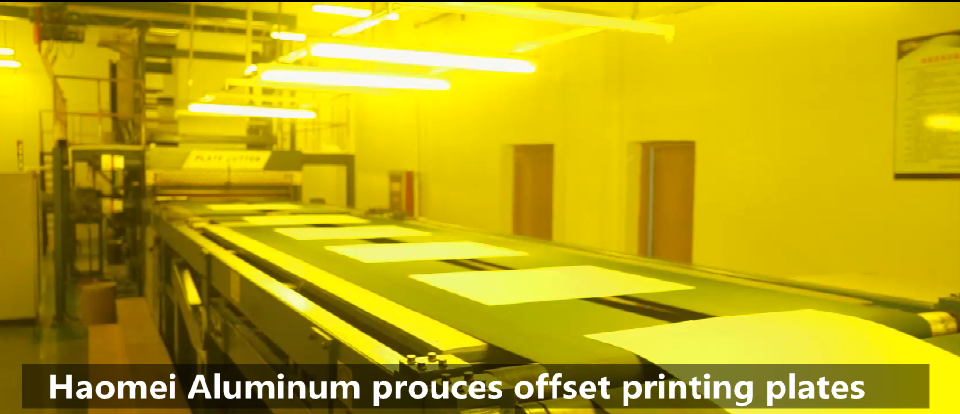

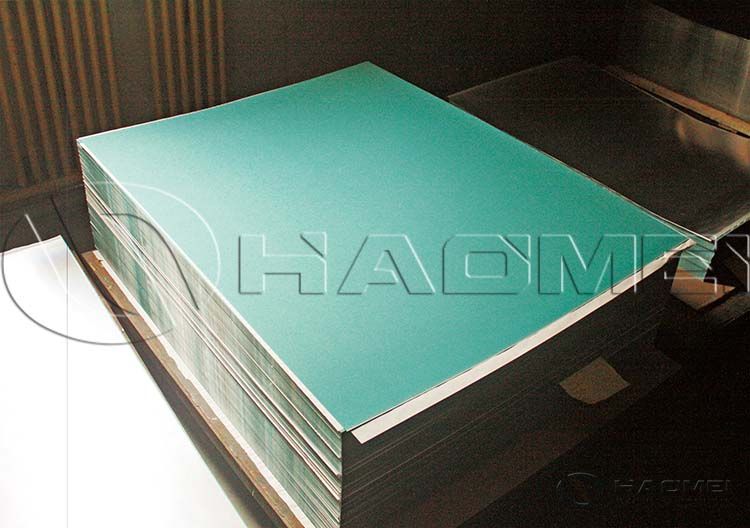

The upstream of the printing plate industry chain mainly includes aluminum coils, acid and alkali and other chemical raw materials, photosensitive materials, liners, packaging boxes and other industries, among which aluminum coils are the most important raw materials, accounting for about 85% of the direct materials of offset printing plates. The downstream is mainly for the printing industry, and the market demand for printing plates is highly related to the development of the printing industry.

In the offset printing plate market, the rinse-free CTP plate does not require chemical reagents to process the plate, avoiding the use of volatile and environmentally damaging chemicals, so it is more environmentally friendly. At the same time, compared with the traditional CTP plate, the rinse-free CTP plate reduces one post-processing process, simplifies the production process, makes the operation more convenient, saves production and preparation time, and avoids performance instability caused by chemical development.

Therefore, the environmentally friendly aluminum offset printing plates will promote the continuous and stable development of offset printing technology. In the future, with the continuous development and improvement of the technology and performance of no-process CTP plates, its market size is expected to grow rapidly, and its market share in offset printing plates will also gradually increase. As one of the big offset printing plates suppliers, we provide different types of PS plate and CTP plates for you.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China