Three Types of Aluminum Printing Plates

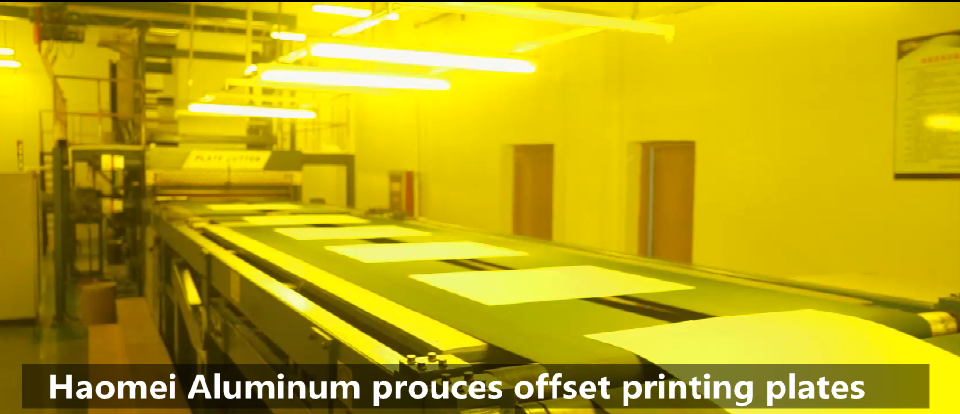

The aluminum printing plates include positive PS plate, CTCP/UV-CTP plate and ctp thermal plate. What are their features and advantages respectively? Welcome to read this page.

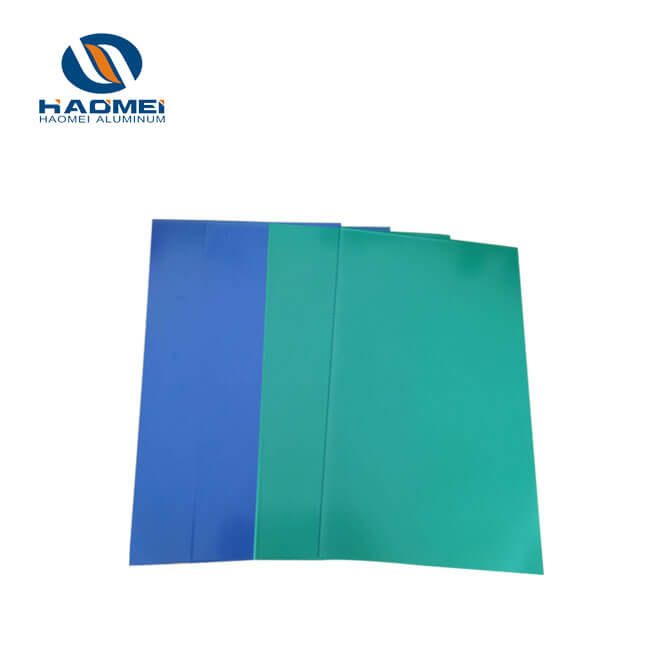

After electrolytic grinding and anodic oxidation, a layer of photosensitive material is coated on the surface of the aluminum printing plates. It includes positive PS plate, CTCP/UV-CTP plate and ctp thermal plate.

Positive PS Plate

The plates used in the CTF process are mainly PS plates, that is, pre-coated photosensitive plates, which are developed to adapt to the rapid development of lithographic printing. The PS plate is composed of the aluminum substrate and the PS plate coating.

The lipophilic part of the PS plate is a diazo photosensitive resin with a height of about 3 μm on the base plane. It is a good lipophilic and hydrophobic film, and ink is easy to spread on it, but water is difficult to spread on it.

If it is baked at a temperature of 230-240°C for 5-8 minutes, the photosensitive film will be enamelized, and the hardness of the printing plate will also be improved, and the printing durability of the printing plate can reach 200,000-300,000 sheets.

The hydrophilic part of the PS plate is aluminum oxide thin film with a height of 0.2-1μm. Its hydrophilicity, abrasion resistance and chemical stability are relatively good, so the printing durability of the printing plate is also relatively high.

Thermal CTP Plate

The business scope of the commercial and packaging printing companies that have high requirements on the quality of printed matter usually include high-end boutique albums and exquisite packaging products, therefore they like to choose thermal CTP technology with quality priority.

The feature of thermal CTP printing is that the printing plate is recorded with a laser with a wavelength of 830nm or 1064nm, and the obtained dot outline is clearer and the dot shape is stronger.

The weakness of thermal CTP plates is their low sensitivity, about tens to hundreds of millijoules per square centimeter. In order to achieve suitable production efficiency, parallel recording technology with multiple laser beams is often used, and the cost of the light source is relatively high.

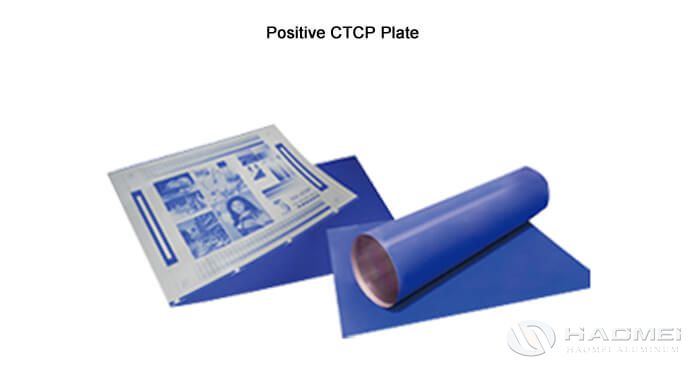

CTCP plate

The CTCP printing press plates printing technology is a computer-to-plate-making solution based on existing printing conditions. Although the price of the CTP has dropped considerably after years of mass production, it still cannot fall to the price level of PS plates, and the plates used in CTCP plate making are cheap conventional printing plates, that is PS plate.

More importantly, because of the use of PS plates, printing companies can maintain the previous state in terms of plate inventory, operator training, and flushing kits without re-investment, so the subsequent maintenance costs are quite low.

Haomei Aluminum has all of these three types of aluminum printing plates for meeting the multiple needs of commercial printing, packaging printing and newspaper printing. Welcome to leave message below to inquire what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China