CTP Plates for Offset Printing

CTP plate realizes the digitalization of offset printing. Among different types of CTP printing plates, thermal and CTP thermal plate are more popular. What are their pros and cons? Learn more.

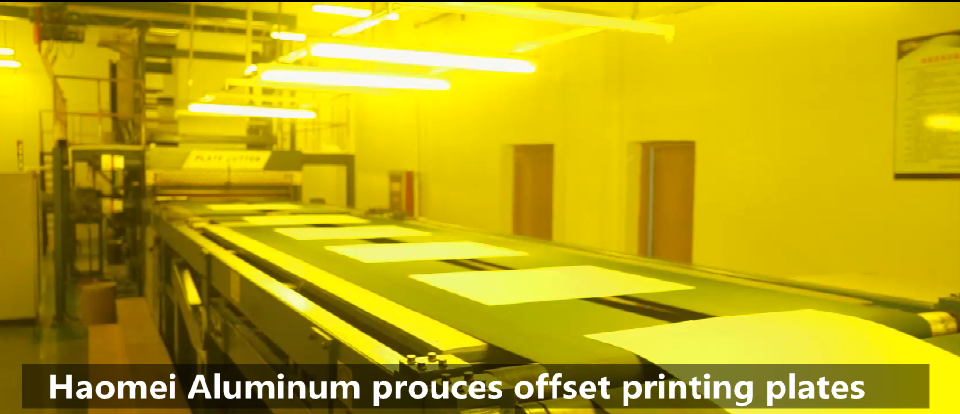

In the wave of offset printing technology's transition from traditional to digital, CTP (Computer-to-Plate) technology is undoubtedly a landmark breakthrough. As the core carrier of this technology, the CTP printing plate directly connects digital graphic information to the offset printing press. Its performance and selection not only determine the quality and precision of the printed product but also affect production efficiency and cost control.

In traditional offset printing processes, multiple intermediate steps such as film preparation and plate exposure are required. This is not only time-consuming and labor-intensive but also prone to errors due to manual operation or film transmission, leading to problems such as misregistration and blurry images. The advent of the CTP plate has completely changed this situation. It can directly receive digital graphic signals output from the computer and accurately "etch" the information onto the printing plate surface through methods such as laser scanning, eliminating the crucial intermediate carrier of film.

For offset printing, the core role of CTP plates is reflected in three aspects: First, improved accuracy. Digital direct plate making avoids signal loss during film copying and plate exposure, enabling the reproduction of finer dots and clearer images, meeting the demands of high-resolution printing. Second, increased efficiency. The time from design finalization to plate installation is significantly shortened, making it especially suitable for short-run, fast-print offset orders. Third, reduced costs. It reduces the consumption of film materials and plate-making consumables, and the reduced error rate decreases the generation of waste plates and printed sheets, resulting in a significant overall cost advantage.

Mainstream CTP Plates

1. CTP thermal plates

Thermal CTP plates can be stored and operated under normal lighting conditions, eliminating the need for dedicated darkroom equipment, greatly reducing the operational threshold and error risk in the production process.

Furthermore, thermal CTP plates exhibit excellent printing durability. Ordinary thermal plates can withstand 100,000-300,000 impressions, while specially treated high-durability thermal plates can even reach over 1 million impressions, making them ideal for long-run, high-end offset printing orders such as packaging and brochures.

However, its shortcomings are also quite obvious. Firstly, the unit price of the plate is relatively high; secondly, it requires higher laser power from the plate-making machine, resulting in a significant initial equipment investment cost.

2. Violet CTP Plate

Violet laser CTP plates use violet laser (wavelength 405nm) as the imaging light source and belong to the category of photosensitive CTP plates. Compared to thermal CTP plates, its plate material and plate-making machine costs are lower, giving it a significant cost-performance advantage.

Violet laser CTP plates have moderate printing durability, typically between 100,000 and 200,000 impressions, which can meet the needs of most mid-range offset printing such as books, posters, and commercial promotional materials. However, it is relatively sensitive to light and requires storage and operation under a yellow safety lamp, which is less convenient than thermal plates. With the maturity of violet laser plate-making technology, its imaging speed is also continuously improving, gradually making up for the early efficiency shortcomings.

3. Silver Halide CTP Plate

Silver halide CTP plates have extremely high photosensitivity and very fast plate-making speed, making them suitable for offset printing scenarios with extremely high production efficiency requirements. Meanwhile, its dot accuracy is extremely high, achieving 1%-99% dot reproduction, making it suitable for high-end printing with fine lines and rich gradient effects.

However, silver halide CTP plates also have significant drawbacks: firstly, they are expensive, with the price of silver halide materials making the unit price of the plate far higher than thermal and violet laser plates; secondly, their printing durability is relatively low, typically limited to 50,000-100,000 prints, making them unsuitable for long-run orders; and thirdly, they are less environmentally friendly, generating silver-containing waste liquid during development, resulting in high treatment costs. Therefore, the application of silver halide CTP plates in offset printing is relatively limited, mostly serving as a supplement for special high-end short-run orders.

Who is the "King" of Offset Printing?

In summary, in the current offset printing market, violet CTP plates have the widest range of applications. This conclusion stems from their balanced satisfaction of the three core requirements of "cost, accuracy, and efficiency."

From the market demand perspective, offset printing is mainly used in mid-range sectors such as book and magazine printing, commercial posters, and packaging boxes. These orders require a certain level of printing precision (e.g., 175 lines per inch), are sensitive to cost control, and demand reasonable production efficiency.

The unit price of violet CTP plates is only 70%-80% of that of thermal plates, and the initial investment in plate-making machines is also lower. The precision fully meets mid-range needs, and the printing durability is suitable for the print runs of most orders (100,000-200,000 impressions).

From the technological development perspective, violet laser CTP technology is becoming increasingly mature. The speed of the new generation of violet laser plate-making machines is approaching that of thermal plate-making machines, and the yellow safety light operating environment requires no large-scale modifications for printing plants, lowering the barrier to technological upgrades.

In contrast, while thermal CTP plates for offset printing offer superior performance, their higher cost deters many small and medium-sized printing plants; silver halide CTP plates, due to cost and environmental concerns, are difficult to achieve widespread adoption.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China