The Requirements of CTCP Plate on Aluminum Base Plate

Aluminum plate is one of the basic elements to make high-quality CTCP plate. What are the influence of the impurities in aluminum alloy on quality of UV-CTP plate? Learn more.

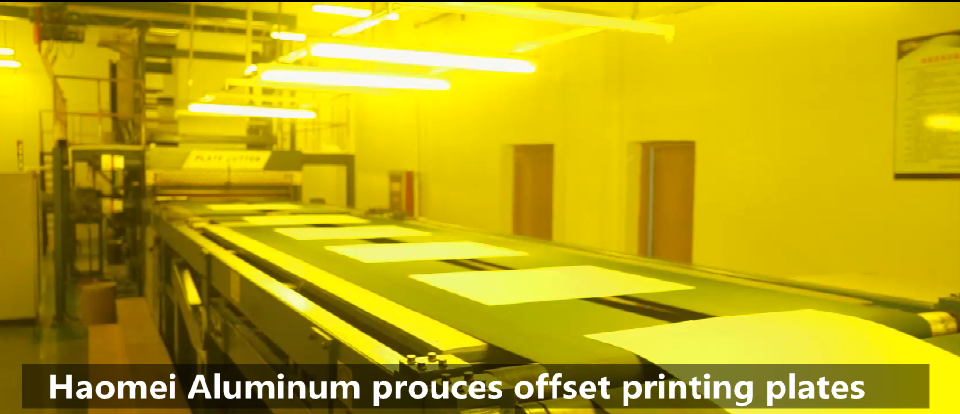

Aluminum plate is one of the basic elements to make high-quality CTCP plate. So far, in the choice of CTCP plate base material, no better material that can replace aluminum plate has been found. There are two treatment methods of aluminum base plate: brush grinding and electric grinding.

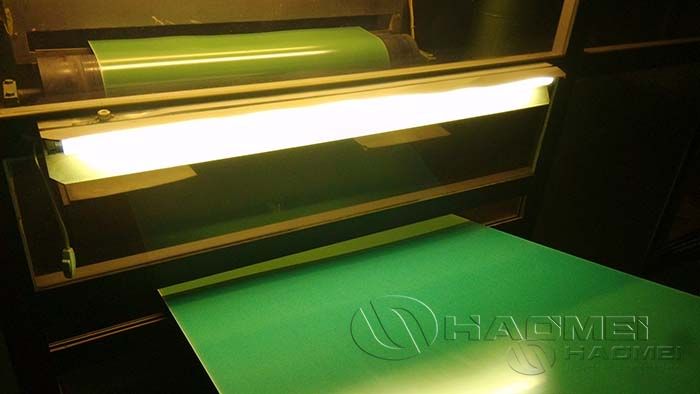

Electrolytic grinding is achieved by chemical methods, that is, acid (usually hydrochloric acid or nitric acid) to corrode the plate surface into a grit layer. Brush grinding and electrolytic grinding have different requirements for the quality of aluminum plate. The brush grinding usually choose 3103 aluminum alloy. While electrolytic grinding chooses 1050 aluminum alloy.

The CTCP Plate is made of f industrial pure aluminum with a content of more than 99.50%. The content of impurities is less than 1.50%. The impurities mainly include Si, Fe, Cu, Mn, Mg, Zn, Ti, Ni,etc. The three elements Si, Fe and Cu are common impurities in aluminum ingots, which can only be controlled and cannot be eliminated completely.

The above-mentioned trace elements contained in the aluminum plate have a certain effect on the quality of its electrolytic oxidation. Silicon is a main impurity, of which the content is generally controlled between 0.05% and 0.35%. If it is over 0.35%, it is detrimental to the uniformity of the aluminum plate's roughened surface.

Generally speaking, the content of iron in industrial pure aluminum is usually the most. Iron has the effect of making the electrolytic coarsening uniform. The copper has a certain solid solution strengthening effect and can accelerate the corrosion, which is conducive to electrolysis. It is better to control the content of copper below 0.05%.

Manganese is to refine the structure. It has a significant impact on the recrystallization process of aluminum and aluminum alloys. Its content should not exceed 0.4%. If it exceeds 0.4%, it will result in reducing printing performance of the UV-CTP plate. Magnesium has a tendency to inhibit the coarsening of recrystallized grains, which can simplify the heating treatment process of the ingot.

Haomei Aluminum has different types of CTP plates, PS plates and CTP plates. Welcome to leave message below to inquire what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China