Offset Printing Plates: PS and CTP Plate

The offset printing plates usually has two types: PS plate and CTP plate. Aluminum base plate is a common choice for making printing plates. What will the aluminum plate quality affect the quality of the finished product? Learn more.

Offset printing is a traditional printing method and the main method of lithographic printing. It refers to the use of offset printing plates to transfer the graphic information to the substrate and finally make paper media such as books and newspaper.

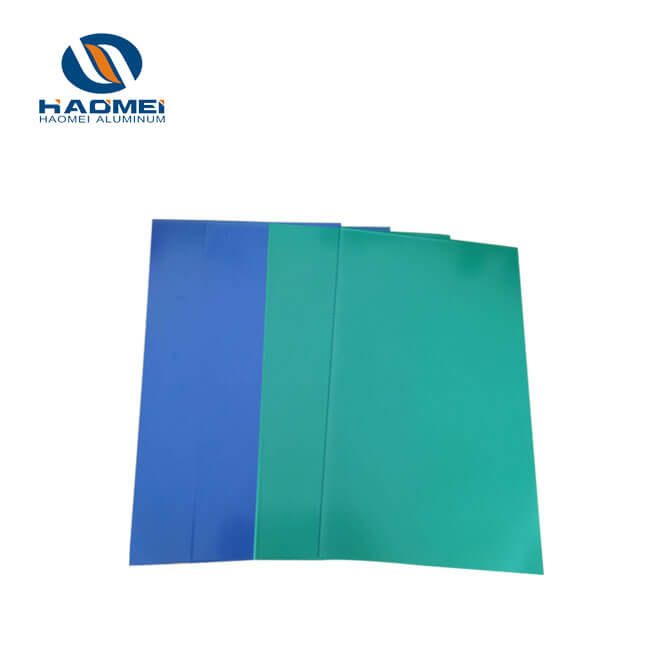

The offset printing plates usually has two types: PS plate and CTP plate. PS plate (Pre-sensitized Plate) is a pre-coated photosensitive plate, and CTP plate is a computer-to-plate. Both of them are made of aluminum alloy plates into thin plates of a certain thickness through hot and cold rolling processes. After the surface is treated by a specific process, it is coated with a layer of photosensitive resin, and after drying, it is made into printing plates for various purposes.

PS/CTP printing plate has the advantages of high printing quality, strong printing ductility, good environmental protection, reasonable cost, high resolution, fast speed and strong reproducibility. Compared with other plate bases, aluminum plate base is of light weight, high strength, moderate wear resistance, good hydrophilicity, high stability and easy surface treatment, occupying a dominant position in the printing plate substrate.

With the continuous development and popularization of electronic technology and laser technology, the technology of the printing industry is also constantly innovating. CTP printing technology uses laser light source to scan and image directly on the printing plate, which saves the process of surface roughening, plate printing, plate repairing, etc., which not only saves the time and cost of plate making. Therefore, the demand for CTP plate keep rising every years.

Aluminum sheet is the core basic material of PS/CTP plates. Commonly used alloy grades are 1050, 1052, 1060 and 1070, and the mass fractions of aluminum are ≥99.50%, ≥99.52%, ≥99.60%, ≥99.70%, and the thickness specifications are in the range of 0.13-0.3 mm.

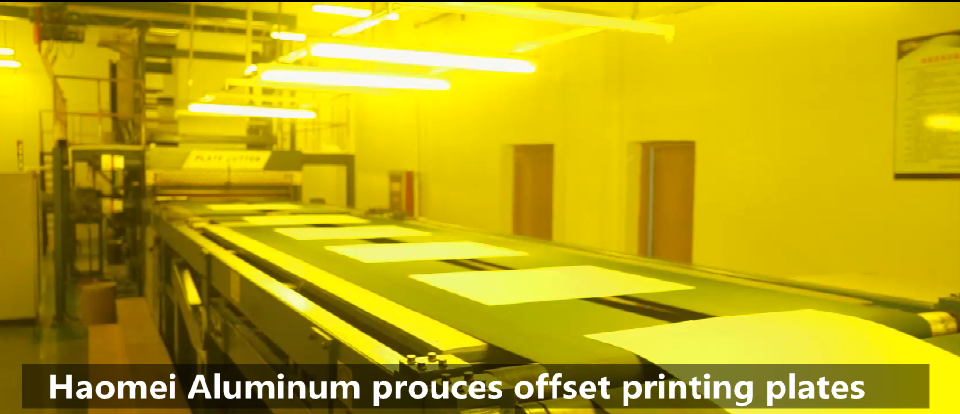

The core production process of high-quality printing plate is to produce uniform fine grains and reasonable grain structure on the printing plate. A large number of dense concave-convex micro-grits are obtained by mechanical or electrochemical methods on the smooth aluminum surface. At present, the most widely used method is electrolytic corrosion. In terms of aluminum sheet, the factors that affect the grain state of the printing plate can be roughly divided into the following three categories:

1. Surface quality: During the production process, some defects on the surface of aluminum sheets, including surface roughness, surface scratches and rolling oil marks,etc.

2. Plate shape flatness:The printing plate has high requirements on the plate shape of the aluminum plate base. The straightness requirement of the PS plate for the aluminum plate base is 2.5I, and the flatness requirement of the CTP plate for the aluminum plate base is 1-2I.

3. Internal quality: It mainly refers to the uneven chemical composition, coarse structure, abnormal shape and size of the compound, etc., inside the aluminum plate.

With mature production technology, Haomei Aluminum can ensure that the aluminum base plate is fully in accordance with the requirements. At the same time, we also provide the finished product PS and CTP plates for the direct use. Welcome to leave message below to inquire what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China