What Is Used for Newspaper Printing

The newspaper printing plates are usually positive PS plates. It consists of four parts: aluminum plate, oxide layer, hydrophilic layer, photosensitive layer. How to improve the newspaper printing? There are five tips.

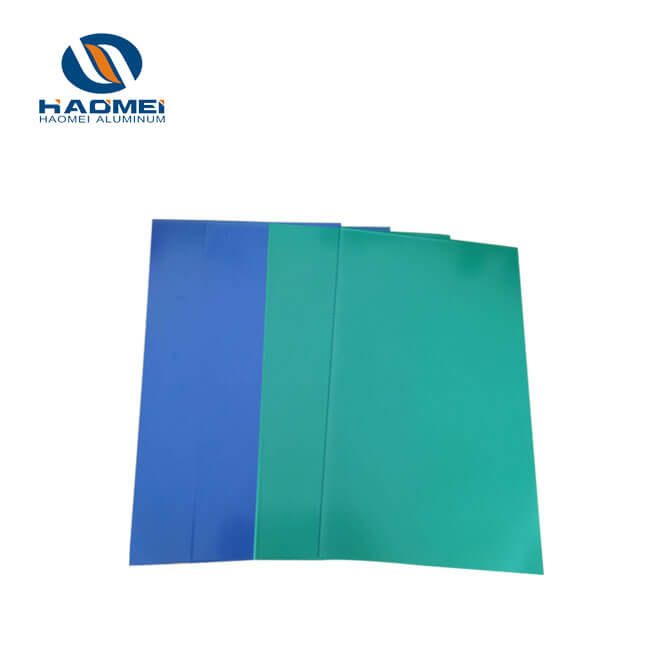

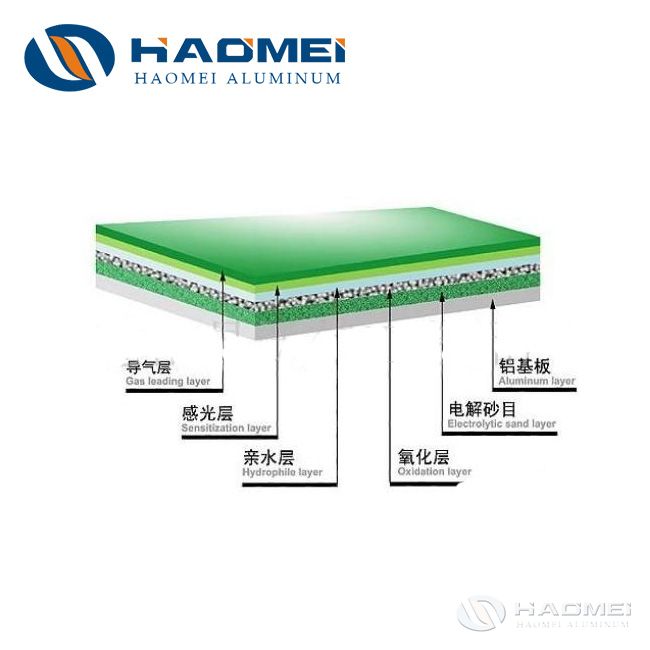

The newspaper printing plates are usually positive PS plates, that is, the pre-coated photosensitive resin plate, which are an offset printing plate formed by pre-coating photosensitive liquid on the surface of the aluminum plate. It consists of an aluminum plate base, an oxide layer, a hydrophilic layer and a photosensitive layer.

1. Plate base: The carrier of printing plate graphics and text, which plays the role of supporting the photosensitive layer.

2. Oxide layer: After anodizing the plate base, a hard oxide film will be formed on the surface of the plate base. This oxide film has strong adsorption, wear resistance and corrosion resistance, which can firmly connect the photosensitive adhesive layer and aluminum plate base.

3. Hydrophilic layer: a hydrophilic film layer formed after anodization and sealing.

4. Photosensitive layer: The photosensitive liquid composed of photosensitive agent, film-forming resin, organic solvent and dye is coated on the surface of the plate base and formed after drying.

As people's requirements for newspaper quality continue to increase, how to improve the quality of newspaper printing has become the focus of major newspaper companies. In terms of the appearance quality of newspapers, problems such as streaks, pasted plates, and dirty plates mainly occur in the production and use of PS plates.

When the PS plate leaves the factory, each printing plate must be protected by a backing paper, so scratches usually will not occur before the printing plate is opened and packaged. However, during the process of the publishing machine making the printing plate and the operator printing on the machine, any irregular link will cause scratches.

1. The protective glue concentration of the plate making machine must be appropriate. If it is too large, it will not be easy to remove on the machine; if it is too small, it will not play a protective role and is an important reason for scratches and smearing.

2. The plate to be printed must be placed with the graphics and text facing each other. Improper placement can easily cause scratches.

3. Operators should handle it with care when bending the plate. The bent corners can easily damage the graphics and text on the printing plate.

4. The water roller and ink roller should always be kept free of foreign matter.

5. Before getting on the machine, face the light and conduct a final inspection of the aluminium printing plates. Under strong light, the scratches on the printing plate will flash brightly and are easily caught by the naked eye.

If you find scratches before going on the machine, lightly apply plate protection glue to the scratches and the problem will be solved. Since the plate base will no longer be hydrophilic due to selective adsorption, applying protective glue after turning on the machine will not help.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China