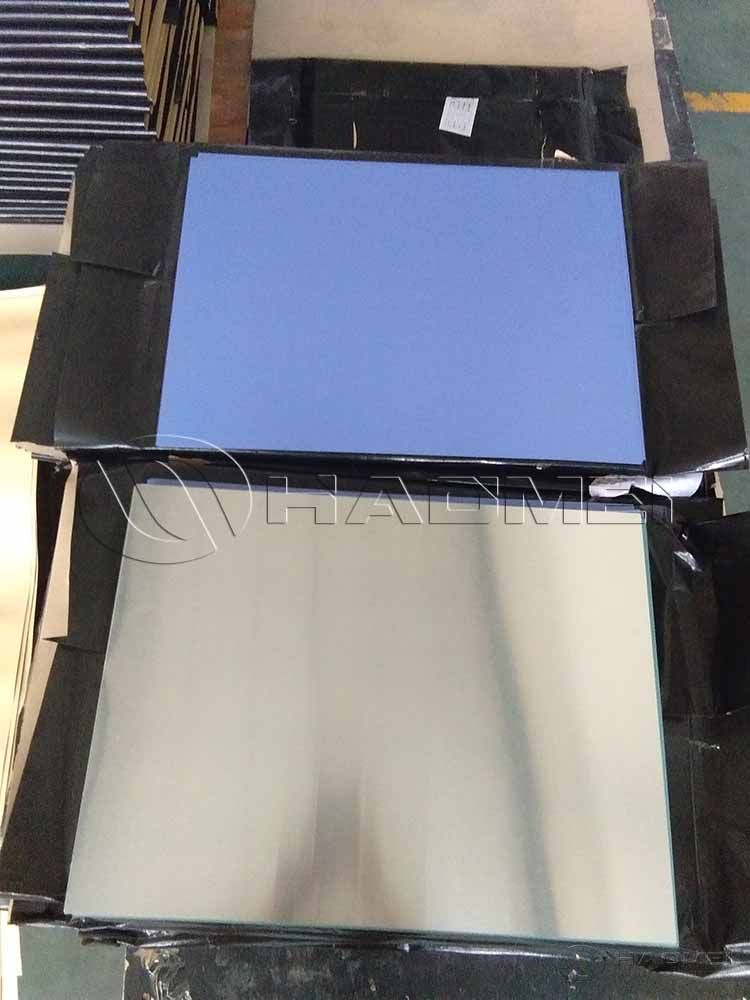

Offset Printing Plate Types: CTP Violet Plate

Offset printing is a type of lithography. There are different offset printing plates, one of which is CTP violet plates. What are its advantages? It has higher accuracy and long life. Learn more.

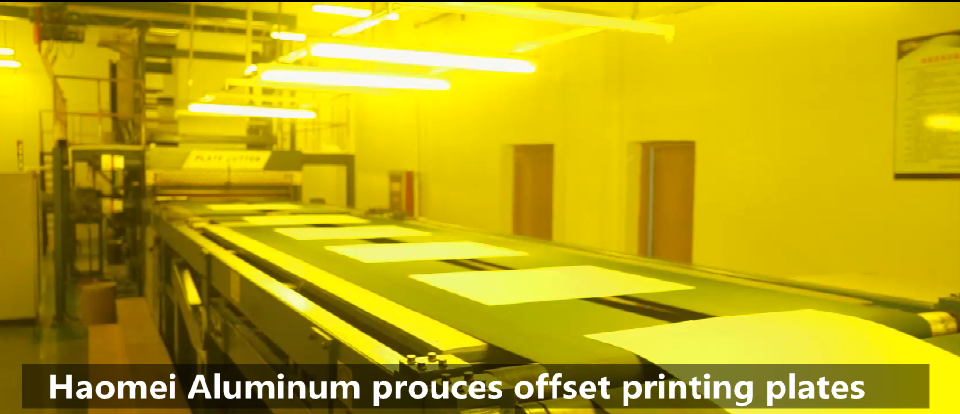

Offset printing is a type of lithography. Simply put, offset printing is a printing method that uses a rubber sheet (rubber cloth) to transfer the image on the printing plate to the substrate. There are different offset printing plates, one of which is CTP violet plates.

The so-called violet light source is a laser with a wavelength of 400nm, and the shorter the wavelength, the greater the energy. Therefore, the violet light source can have a higher imaging speed than other commonly used CTP light sources such as green light (532nm) and red light (830 or 1064nm).

The principle is that even if the purple laser stays on the plate for a short time, it can still provide enough energy to stimulate the reaction of the drug film on the plate. Using this feature, equipment manufacturers can increase the scanning speed.

For example, the current scanning speed of infrared laser is 20,000 lines/minute, while the scanning speed of green laser can be as high as 55,000 lines/minute, which is equivalent to scanning a 1024x800mm folio at 2400dpi in 1 minute and 46 seconds (other operating time is not included).

Also because of the physical optical properties, another feature of the shorter wavelength of light is that the laser spot will be smaller. Therefore, it is allowed to scan finer dots on the plate. The previous light source can generally only show 200lpi (1-99%) dots on the photosensitive plate, while the use of purple laser can increase the accuracy to 250lpi.

Since the digital plate used with purple laser does not work with red light and green light, the purple laser CTP equipment can use yellow safety lights (light + green light = yellow light) to provide operators with a brighter working environment and make operation more convenient.

Although the maintenance period provided by laser manufacturers for purple lasers is the same as that of green lasers in the past, which is also 3,000 hours,due to the operating characteristics of purple lasers, the laser will only be activated when imaging is actually performed, and the rest of the time will not consume the life of the laser.

The operating mode of other lasers is to activate the laser at the same time when the machine is turned on, which has a longer actual life than other CTP laser light sources. At the same time, since similar lasers are also widely used in other industries (such as commonly used DVD optical disc players), they can be mass-produced due to the large number of users to reduce costs, making the price of this light source lower than other CTP light sources.

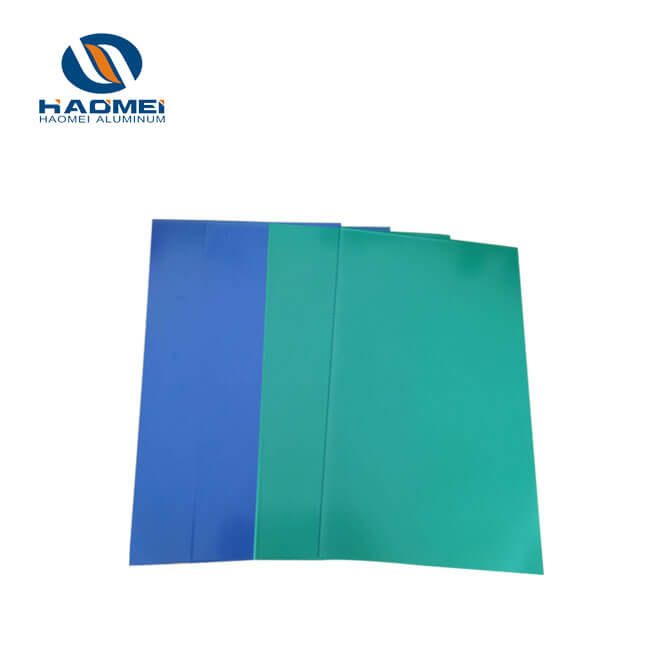

If we compare the advantages of the above-mentioned CTP violet plates with the common CTP thermal plate, thermal products are slightly better in precision, but there is no obvious advantage in other aspects. Haomei Aluminum provides rich types of aluminium plate printing, welcome to leave message to tell us what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China