Which is Better: CTP or CTCP Printing Technology

Thermal, violet ctp and ctcp plate making technology each has its own advantages and disadvantages. Which is better? There is a comparison between them like in cost. Learn more.

At present, direct-to-plate making machines are divided into two categories. One type requires special plates, such as violet and thermal CTP plate. Its expensive plates discourage many users who very much hope to adopt CTP technology. The other one can be applied to traditional PS plate, such as CTcP technology.

Thermal, violet ctp and ctcp plate making technology each has its own advantages and disadvantages. Based on the actual needs of the company's market positioning and technological transformation capabilities, and comprehensive consideration of time, quality, cost and other aspects, we can rationally delineate the option that is most suitable for you.

Ⅰ CTP technology that promotes the development of digital printing

1. Features of CTP technology

The plate-making equipment has diversified specifications, ranging from four-format to full-sheet and even super-large format.

The digital workflow is easy to operate and user-friendly, and can provide more options for highly automated functions.

It is equipped with the most advanced automated workflow software.

Through CIP4, full-page ink channel data is directly generated and transmitted to the printing press, which shortens the color chasing time, reduces the printing paper, and improves the production efficiency of the printing press.

Using special screening technology, the output can be selected between FM screen, AM screen, and hybrid screen, with good detail reproduction, ensuring the stability of printing colors, and achieving high-fidelity printing.

2. Types of ctp plates

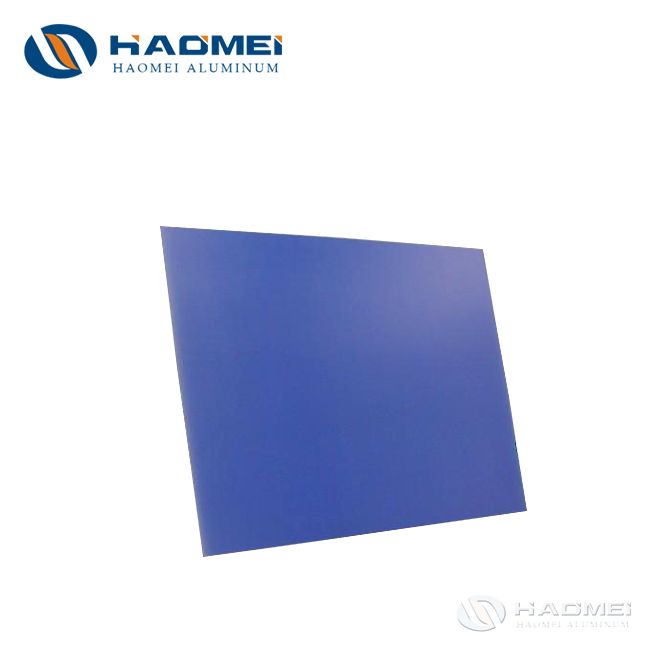

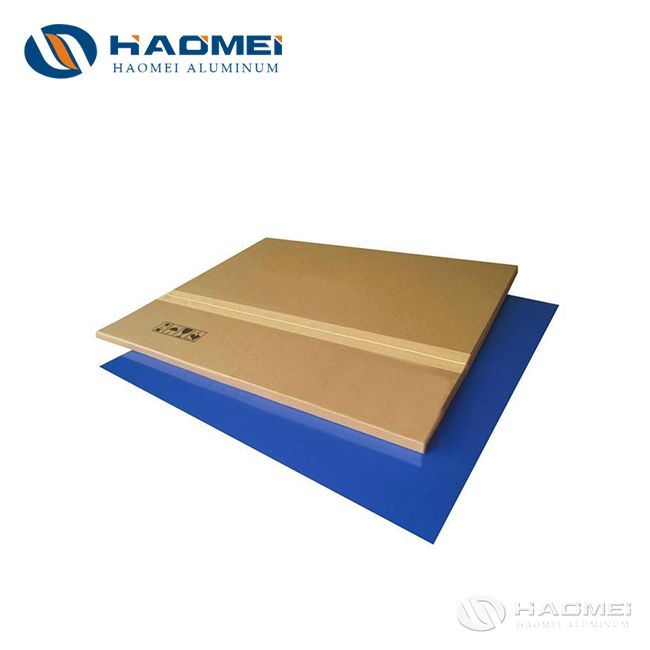

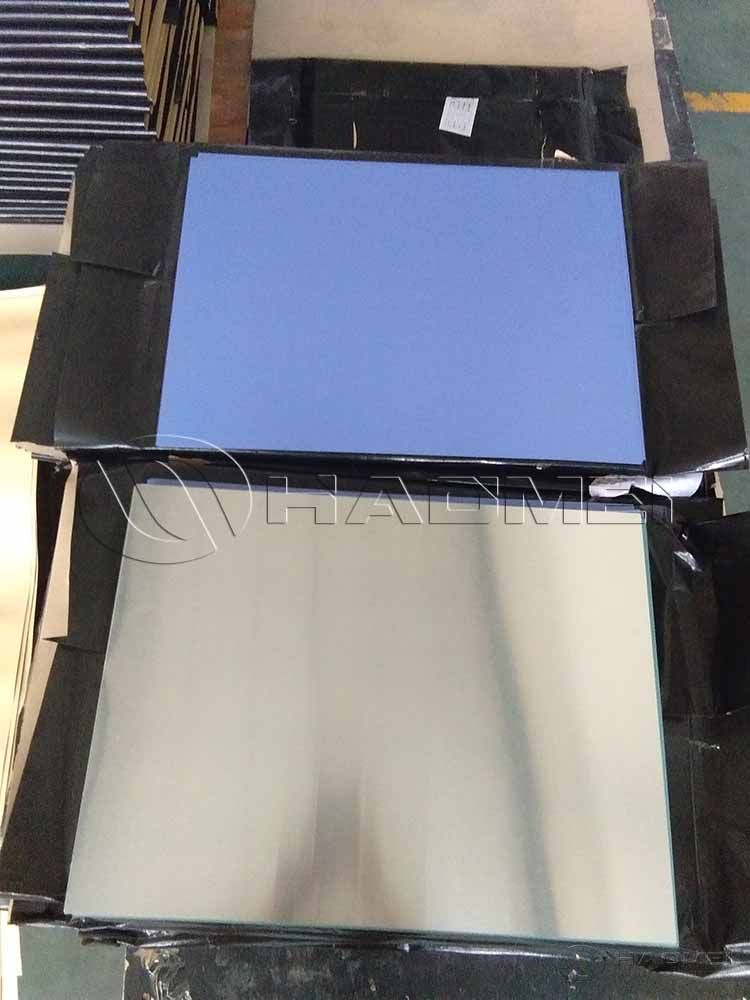

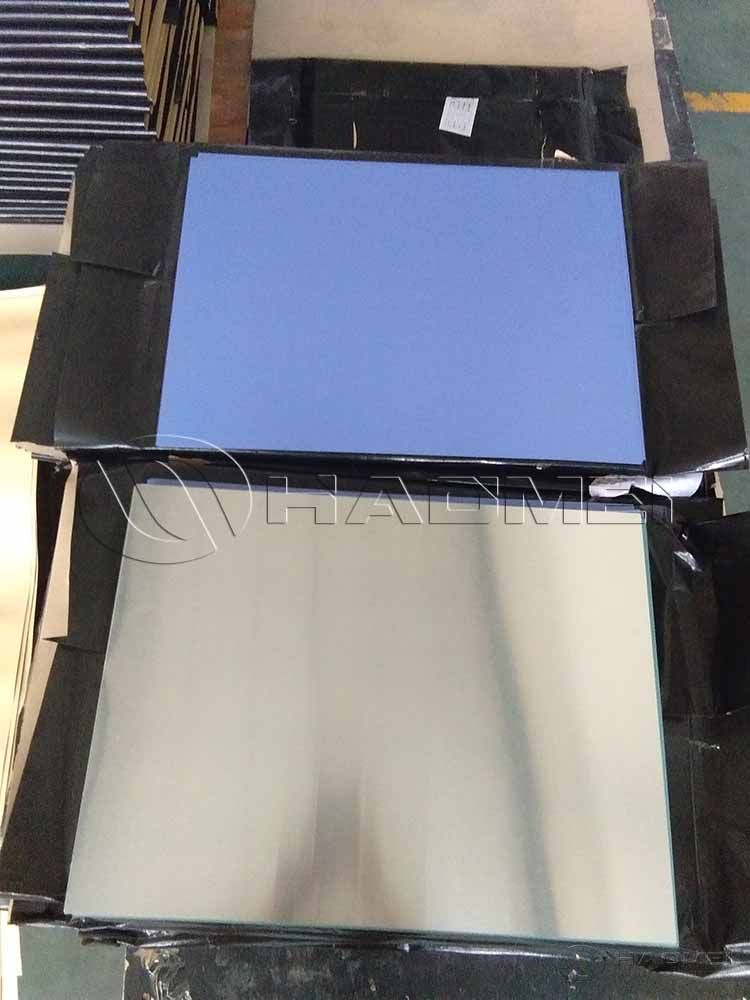

It mainly includes photosensitive CTP, thermal CTP and Violet CTP plate.

Ⅱ CTCP technology

1. Technical characteristics

CTcP is the English abbreviation of Computer To Conventional Plate, which refers to computer direct plate making on traditional PS plates. It is a form of realization of CTP process. However, no changes are required in the prepress process and on-machine printing.

The basic imaging principle of traditional UV printing plates is followed, and the light source has basically not changed. The only requirement is that a UV-Setter is configured in the system. Most offset printing plates can be exposed and imaged using UV-Setter.

It not only has the high quality and efficiency of CTP, but also retains the easy operation and stable performance of traditional plate printing.

2. Unique advantages

l It significantly reduces pre-press production costs. Firstly, it simplifies the process and reduces the traditional processes; secondly, it is suitable for any traditional PS plate, using conventional developing machines and processing chemicals (chemical-free plates have been introduced), and can be easily operated under bright room conditions; thirdly, there is no need to change the existing hardware configuration. Data in 1bit/tiff format can be used, and RIP data can be used. There is no need to use a special network interface, and it can be connected to the existing network environment to achieve low-cost operation and high system operation. The comprehensive maintenance cost can be reduced by about 40% compared with CTP using special plates.

High printing quality and efficiency. Using square dot imaging, high-quality printing can be achieved with lower resolution, and can significantly shorten RIP time, reduce the amount of data processed, save computer system memory, and achieve faster exposure, etc. At the same resolution, higher reproduction quality can be achieved. Dot-matrix one-to-one digital imaging of PS plates can eliminate dot expansion and dirty spots during plate making.

It reduces printing debugging time and material loss. There is no need for printing plate positioning, so there is no need to re-make the plate due to inaccurate positioning, and it avoids spending a lot of time on proofreading when printing on the machine. It can minimize the time for plate changeover and machine debugging in short-run printing.

It gives full play to the potential performance of the traditional PS plate. In traditional plate making, due to the inevitable dot expansion and dot loss during film printing, the exposure range of PS plates is only 2%-97%, and the controllable range of printing is only about 5%-85%. With digital direct imaging technology, the PS plate can reproduce 1%-100% of dots excellently due to the elimination of dot expansion and loss, and the printing controllable range has also been expanded to 1%-99%.

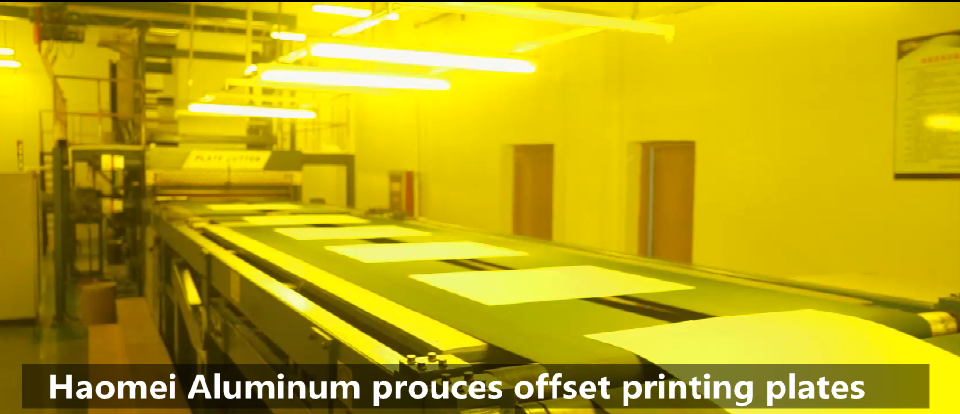

It has fast, stable and smooth integration with traditional PS printing process. The PS plate's on-machine printing and image reproduction capabilities have been tested by the market for a long time and have been recognized. The technical process has been perfected and has been the most widely used in the printing industry. The introduction of CTcP can continue to use the original plate processor and developer solution; and can reduce the downtime for plate change during printing. The original ink balance, printing pressure and other printing parameters do not need to be retested. It not only ensures the stability of printing, but also ensures economy and high efficiency. As one of the big ps plate and ctcp plate manufacturers in China, Haomei Aluminum can offer you different types of PS, CTP and ctcp plate.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China