The Different Requirements of PS/CTP Plate on Aluminum Plate

What are the different requirements of PS/CTP Plate on Aluminum Plate? It involves surface requirements, geometrical size and electrolytic performance. Learn more.

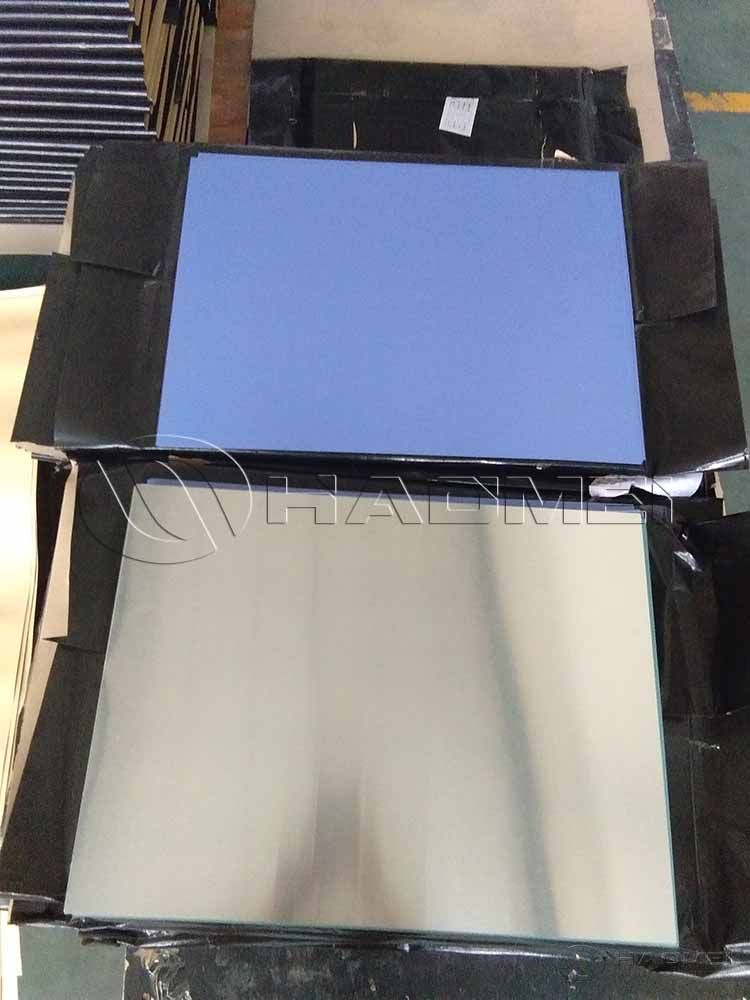

The CTP offset printing plates’ basic requirements for the appearance of the aluminum plate base are clean, flat, free of cracks, corrosion pits, spots, vents, scratches, creases, marks, peeling, etc. There is no slight color difference.

The PS plate can ignore the above problems. The main reason is that the CTP equipment uses scanning imaging, unlike the PS plate, which uses a vacuum method to make the plate and the film close. If the CTP plate flatness is poor, it will affect the laser imaging quality.

The difference between CTP plate and PS plate on the geometrical size requirements of aluminum plate base:

1. Thickness difference

The thickness of the aluminum plate base for CTP thermal is generally 0.280mm, which is slightly thicker than the PS plates currently produced (the thickness of the PS plate base is 0.270mm±0.005mm). Since the aluminum plate base is thicker, the printing plate stiffness will be better, and it is not easy to bend.

2. Width difference

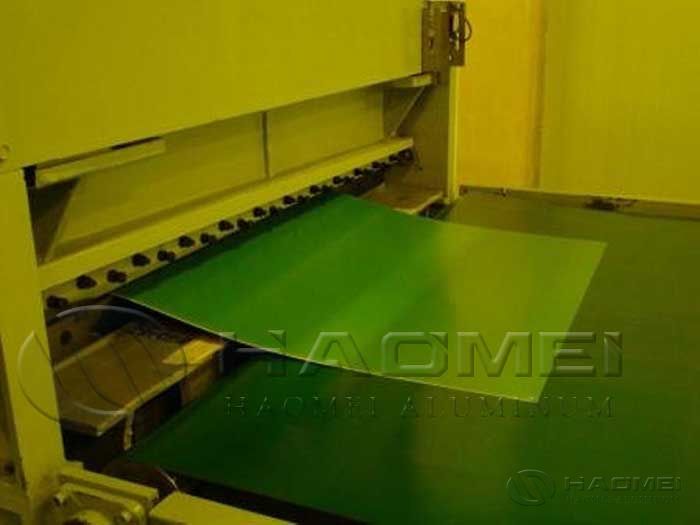

Since the production of CTP plates does not install an online trimming device, the width tolerance of the aluminum coil is required to be ≤±0.5mm, preferably without tolerance. There are also clear requirements for the cutting quality of aluminum coils, that is, there should be no burrs, flounces, etc. on both sides of the aluminum coil after slitting.

3. Vertical and horizontal uniformity

The longitudinal and transverse thickness tolerances of the aluminum plate base should be ≤±0.005mm. The thickness deviation will affect the plate making, and the parameters set by the CTP plate making machine are generally not allowed to be adjusted casually.

The difference between CTP plate and PS plate on the electrolytic performance requirements of aluminum plate base:

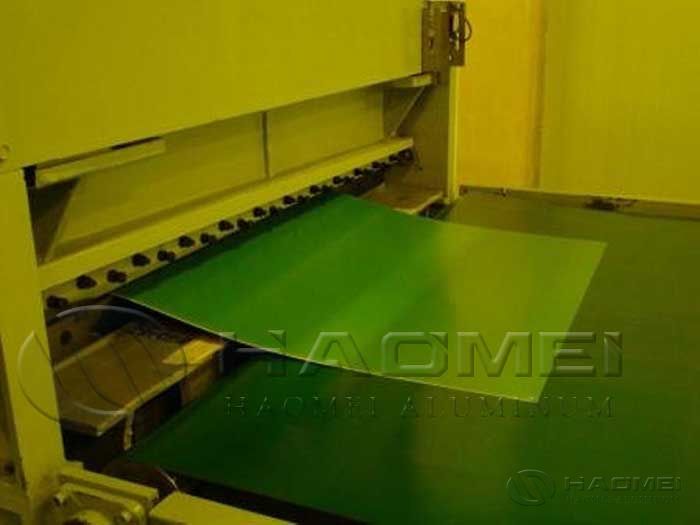

Because CTP printing plates are mostly used for high-end color printing, the basic grain value of CTP plates is finer than that of PS plates. The reduction is directly related to the surface roughness of the plate base, that is, the grain value of the plate base. The thicker the grain, the worse the reducibility of the dots and lines.

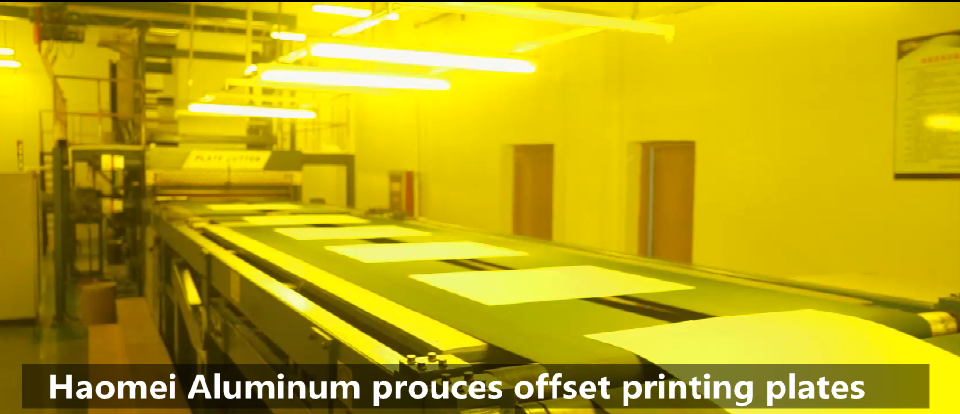

To prepare a fine and uniform grain, the internal composition of the aluminum plate base is very important, which is related to the composition of the aluminum alloy. Haomei aluminum plate for CTP thermal has good physical and mechanical properties and can significantly improve its electrolysis suitability. Welcome to leave message below to inquire it.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China