What Will Affect PS Printing Plate Quality

In terms of Ps printing plate itself, aluminum sheet base and coating quality has great effect on its quality. What are other influencing factors? Like platemaking process. Learn more.

In the printing industry, PS printing plate has become one of the mainstream printing plate making methods due to their high efficiency and stability. Whether it is exquisite books and picture albums or colorful posters and flyers, PS printing plates play an important role in them. However, the quality of PS printing plates is not static, and it is affected by a combination of factors.

Raw material

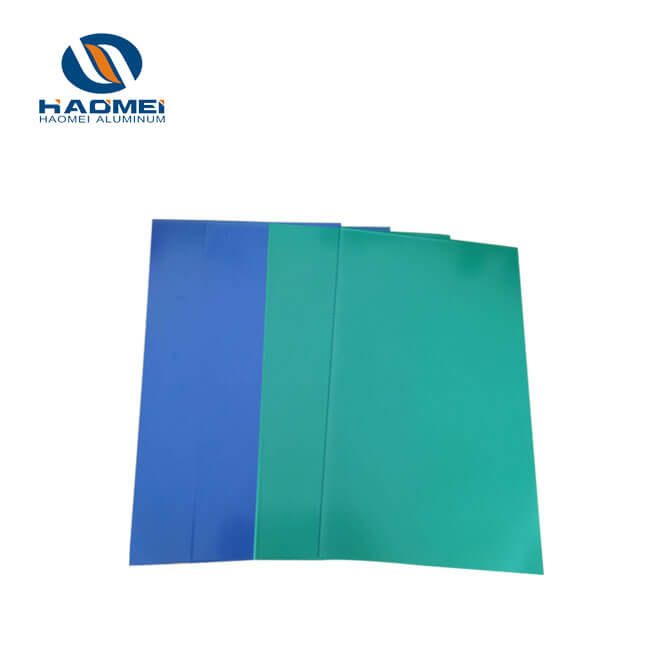

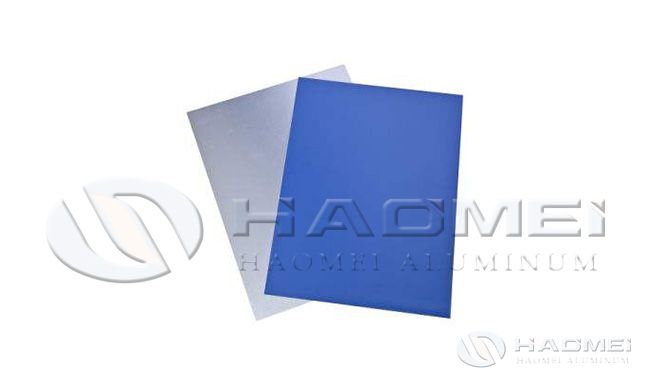

The raw materials of positive PS plates mainly include substrate and photosensitive coating. The substrate is generally made of aluminum plate. The purity, flatness and surface roughness of the aluminum plate have a significant impact on the quality of the PS plate.

Aluminum plates with high purity are not easy to oxidize, which can ensure the stability of the plate surface; plates with good flatness can have more uniform contact with the rubber blanket during printing, which can reduce printing color difference; and aluminum sheets with moderate surface roughness can make the photosensitive coating adhere better and improve the image reproduction ability. If there are impurities or poor flatness on the aluminum plate, it will cause problems such as dot deformation and blurred images during printing.

The performance of the photosensitive coating is also critical. Its sensitivity, resolution and printing durability directly determine the platemaking quality and service life of the PS plate. A coating with high sensitivity can complete platemaking in a shorter exposure time, improving production efficiency; a coating with high resolution can accurately restore image details and present a delicate picture effect; a coating with strong printing durability can withstand more printing times and reduce the frequency of plate replacement.

Photosensitive coatings of different brands and models have differences in these performance indicators, so choosing a high-quality photosensitive coating is an important part of ensuring the quality of the PS plate.

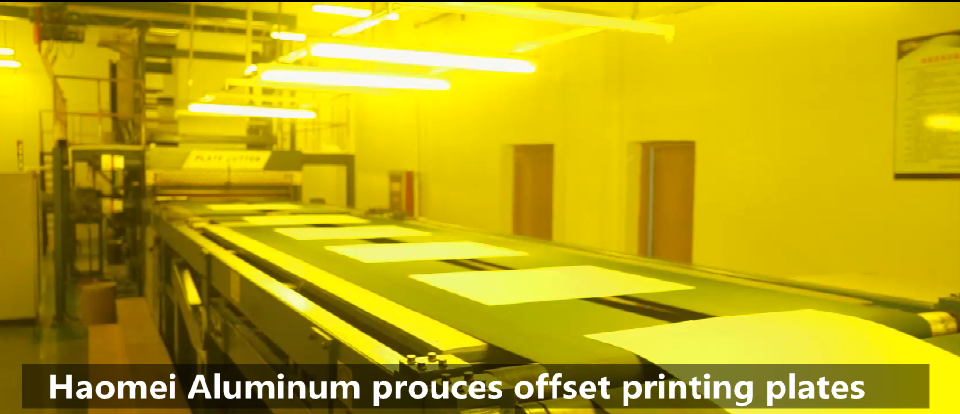

Plate making process

The exposure, development, and washing process in the platemaking process all have a direct impact on the quality of PS printing plates. The control of exposure time is crucial. Insufficient exposure will cause the photosensitive layer of the non-image part to fail to fully solidify and be dissolved during development, resulting in a dirty plate phenomenon; overexposure will cause the photosensitive layer of the image part to over-solidify and incomplete development, resulting in dot shrinkage and reduced image clarity.

The concentration, temperature and development time of the developer also need to be precisely controlled. If the concentration is too high or the development time is too long, the photosensitive layer of the image part will be excessively dissolved, resulting in the loss of dots; if the concentration is too low or the development time is insufficient, the photosensitive layer of the non-image part will remain, causing printing failure.

The flushing process should not be ignored either. If the flushing is not thorough, the residual developer will continue to corrode the plate surface and affect the printing quality. In addition, the accuracy and stability of the platemaking equipment will also affect the platemaking effect. Advanced platemaking equipment can more accurately control the exposure and development parameters to ensure the quality consistency of the PS plate.

Environmental factor

The production and storage environment of PS printing plates also has an important impact on their quality. At the same time, the light intensity and exposure time in the environment also need to be paid attention to. PS plates should avoid being exposed to strong light for a long time, otherwise the photosensitive coating will be sensitized in advance, affecting the quality of plate making.

In addition, the cleanliness of the working environment is also very important. Once dust and impurities adhere to the plate surface, they will form white spots or dirt during printing, destroying the beauty of the printed product.

The skill level and experience of operators play a decisive role in the quality control of the PS plate offset. Skilled operators can accurately adjust the platemaking parameters according to different printing requirements and raw material characteristics, and promptly discover and solve problems that arise during the platemaking process.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China