What Do You like to know About Embossed Aluminum

How to calculate the weight of 0.25 aluminum diamond plate 4x8 sheet? What are the uses of the embossed aluminum? What are different surface processing methods? Learn more here.

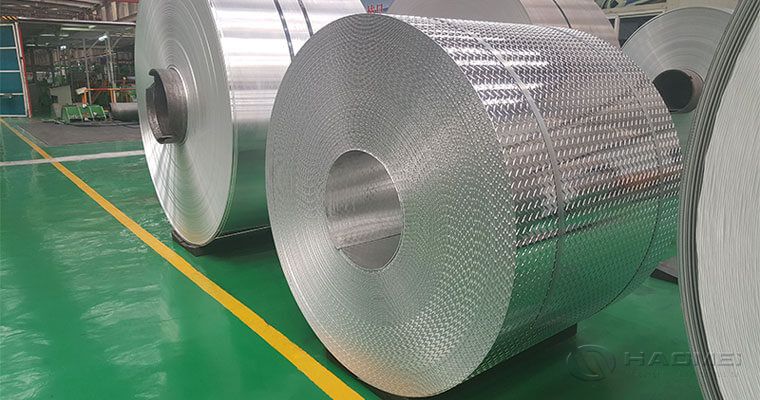

Many customers do not know how to calculate the weight when buying aluminum tread plate. In fact, there is a theoretical calculation formula for patterned aluminum plates. You only need to multiply the thickness of the aluminum sheet by the density of the aluminum plate to calculate the weight. The calculation result is not much different from the actual weight, which makes it easier for users to calculate costs.

Take 5 bar aluminum tread plate for example. The thickness we calculate is based on the thickness of the patterned aluminum plate substrate, and the calculation method is aluminum plate thickness (in millimeters) * aluminum plate density (2.71) * length (in meters) * width (in meters) = aluminum tread plate weight. The weight of 0.25 aluminum diamond plate 4x8 sheet=51.14kg.

Uses of aluminum diamond sheet

1. Lighting

2. Solar reflectors

3. Building appearance

4. Interior decoration: ceiling, wall, etc.

5. Furniture, cabinets

6. Elevators

7. Signs, nameplates, bags

8. Car interior and exterior decoration

9. Interior decoration: such as photo frames

10. Household appliances: refrigerators, microwave ovens, audio equipment, etc.

11. Mechanical parts processing

12. Mold manufacturing

13. Chemical/insulation pipe coating

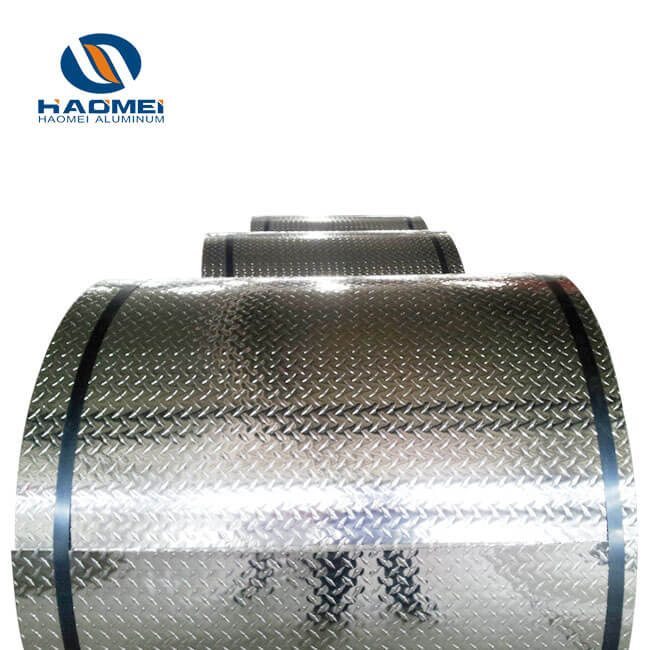

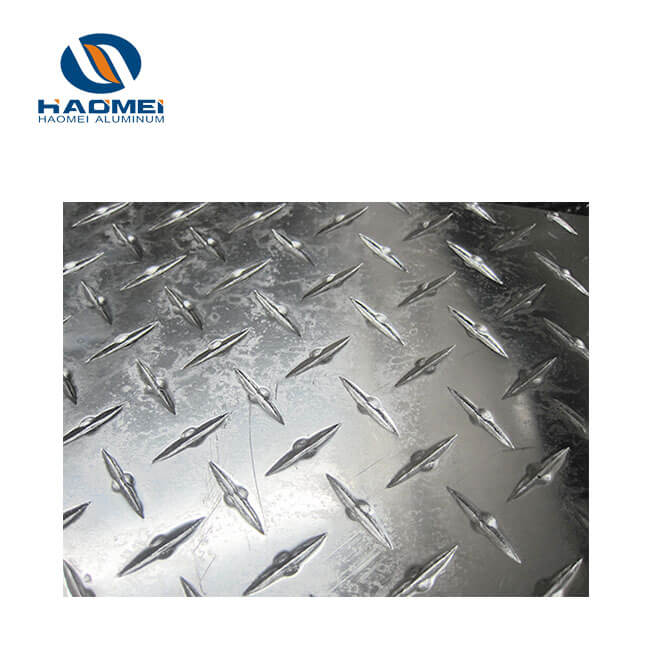

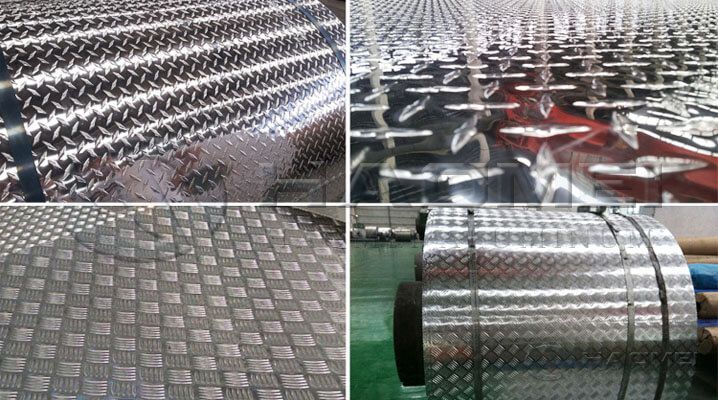

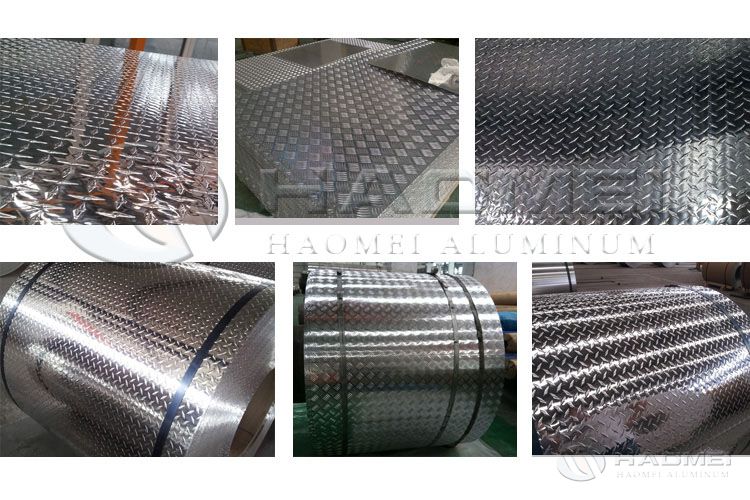

Embossing process

Embossing is a process of forming a predetermined pattern on the surface of an aluminum plate through a rolling process. This process is usually carried out between high-pressure rollers, and the raised pattern on the pattern roller is embossed onto the aluminum plate. Various patterns can be produced, such as diamonds, orange peel patterns, 5 bars,etc. In addition to the decorative effect, the embossed aluminum can also enhance the anti-slip performance.

Spraying process

Spraying usually refers to spraying paint on the surface of aluminum plate to form a protective layer or decorative layer. Surface cleaning, grinding and other pretreatments are usually required before spraying. Spraying not only provides color and texture, but also enhances corrosion resistance, weather resistance and chemical resistance.

Anodizing process

Anodizing is to form a protective layer of aluminum oxide on the surface of aluminum plate by electrochemical method. This process will form an oxide film on the surface of aluminum with a certain hardness and corrosion resistance. Anodizing not only improves the surface hardness and wear resistance of aluminum plate, but also enhances the decorative and insulating properties.

Surface grinding and polishing

For some special-purpose aluminum plates, surface grinding and polishing may be required to obtain a mirror or semi-mirror effect.

This treatment not only increases the visual appeal of the product, but also helps to improve the performance of cleaning and easy maintenanc

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China