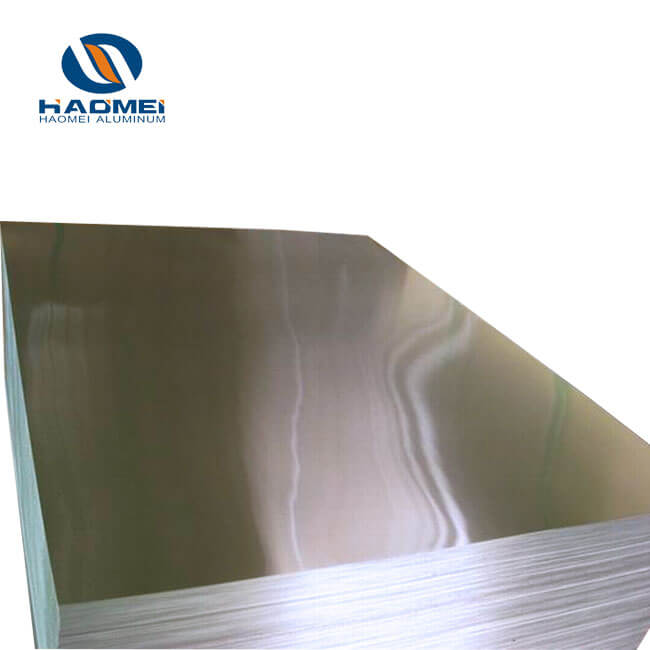

What Are Properties and Uses of 1100 Aluminum Sheet

1100 aluminum sheet is of low cost and wide application. What are the 1100 aluminum sheet properties and uses? With continuous casting and rolling, our 1100 aluminum price is cheaper.

1100 aluminum sheet is of good elongation and tensile strength, good plasticity, corrosion resistance, electrical conductivity and thermal conductivity. The production process is relatively simple and its production technology is relatively mature, so its price is much cheaper.

1100 aluminum properties

1. Low density. The density of pure aluminum is close to 2700KG/M³, which is about 35% of the density of iron. The strength of pure aluminum can be increased by cold working, and can be further strengthened by adding magnesium, zinc, copper, manganese, silicon, lithium, scandium, etc.

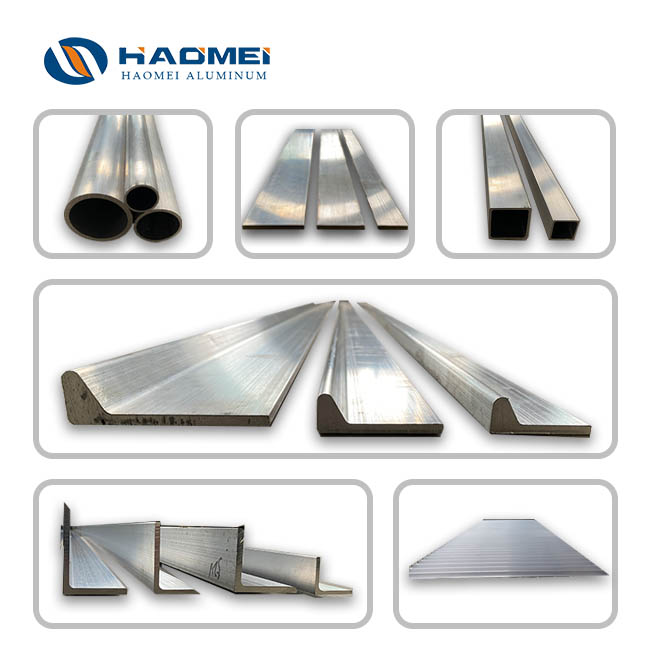

2. Easy to process and resistant to corrosion. 1100 aluminum plate can be cast by any casting method. It can realize high speed machining such as turning, milling, boring and planing. It has good resistance to atmospheric (including industrial atmosphere and marine atmosphere) corrosion and water corrosion.

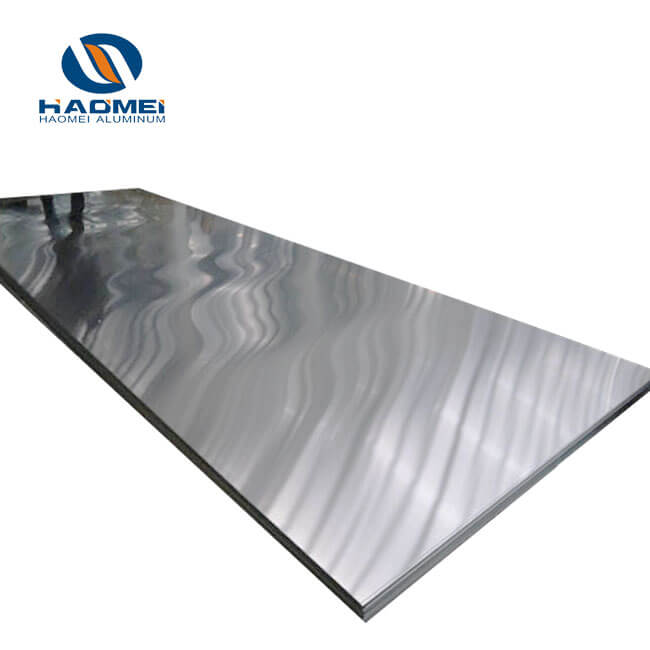

3. Good conductivity and reflectivity. The electrical conductivity and thermal conductivity are quite good, second only to silver, copper and gold, and the white reflectivity of the polished aluminum surface reaches more than 80%. At the same time, it has good reflection properties for infrared, ultraviolet, electromagnetic waves and thermal radiation.

4. Non-magnetic. It has the characteristics of sound absorption, anti-nuclear radiation and beautiful appearance.

1100 aluminum uses

1100 aluminum plate is mainly used for automobile heat insulation boards, billboards, building exterior decoration, wall decoration, electrical lighting, heat exchangers, kitchen utensils, conductor materials, chemical equipment, electronic equipment, inland ship equipment, various containers (wine cans, Pressure tanks, tea stoves, etc.), instruments and meters and other products with lower strength requirements.

Manufacturing process

Compared with the traditional production process, 1100 aluminum sheet continuous casting and rolling can save investment, increase output, reduce production cost, and greatly shorten production cycle.

Its process flow is: Aluminum water refining and continuous casting machine- roller furnace- high pressure water descaling- vertical rolling mill- finishing- cooling- coiler- sampling inspection- weighing- marking.

Casting and rolling process parameters are: front box temperature 685~695℃; rolling speed: 1000~1200mm/min; cooling water temperature <50℃; cooling water pressure: 0.15~0.7MPa, rolling thickness of medium and heavy plate: 7.4mm.

As a big 1100 aluminum sheet supplier, Haomei Aluminum can ensure best price and short delivery. We also have other 1xxx aluminum alloy sheets. Welcome to leave message below to inquire what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China