What Are Different Surface Treatments of Aluminum Coil

In the large family of metal materials, aluminum coils are widely used in many fields such as construction, electronics, and packaging due to their many advantages such as light weight, corrosion resistance, and easy processing. The rich and diverse surfa

In the large family of metal materials, aluminum coils are widely used in many fields such as construction, electronics, and packaging due to their many advantages such as light weight, corrosion resistance, and easy processing. The rich and diverse surface treatment methods of aluminum coils not only further improve its performance, but also give it a unique appearance and texture, meeting the diverse needs of different industries.

1. Mirror treatment

Process principle

The mirror aluminum coil is to reduce the roughness of the surface of the aluminum coil by mechanical polishing, chemical polishing or electrolytic polishing, so that it can achieve a mirror-like bright and smooth effect. Mechanical polishing mainly uses a high-speed rotating polishing wheel to remove the tiny protrusions on the surface of the aluminum coil by friction, so that the surface becomes smooth.

Chemical polishing uses a specific chemical solution to corrode and dissolve the surface of the aluminum coil, so that the protrusions dissolve faster than the concave parts, so as to achieve a smooth and bright surface

Electrolytic polishing is in the electrolyte, through the action of electric current, so that the microscopic protrusions on the surface of the aluminum coil are preferentially dissolved, and then a mirror effect is obtained.

Features

High gloss: The mirror finish aluminum coil has extremely high gloss and can reflect clear images, adding a luxurious and high-end texture to the product. In the field of architectural decoration, the mirror-finished aluminum coil used for interior wall and ceiling decoration can reflect light, making the space appear brighter and more open, creating a high-end atmosphere.

Excellent flatness: After mirror treatment, the surface flatness of the aluminum coil is excellent, with almost no flaws and unevenness. This feature makes it very useful in the field of electronic equipment that requires extremely high surface accuracy. For example, as the shell of electronic equipment, it not only has a beautiful appearance, but also effectively improves the overall quality of the product.

Good corrosion resistance: During the polishing process, a dense oxide film will form on the surface of the aluminum coil, which further enhances the corrosion resistance of the aluminum coil, allowing it to maintain good appearance and performance in a harsh environment.

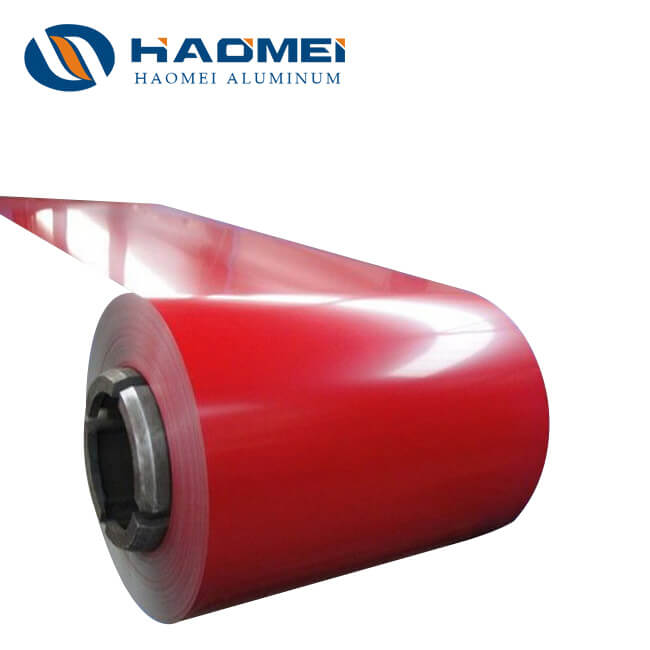

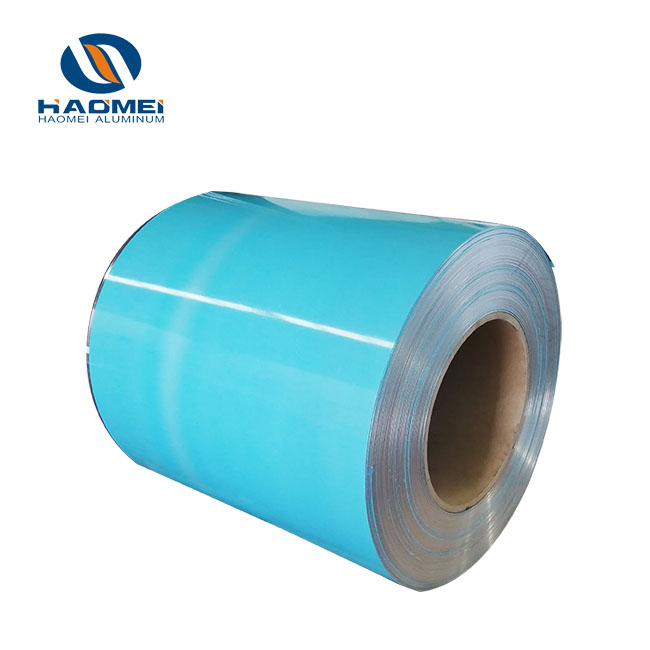

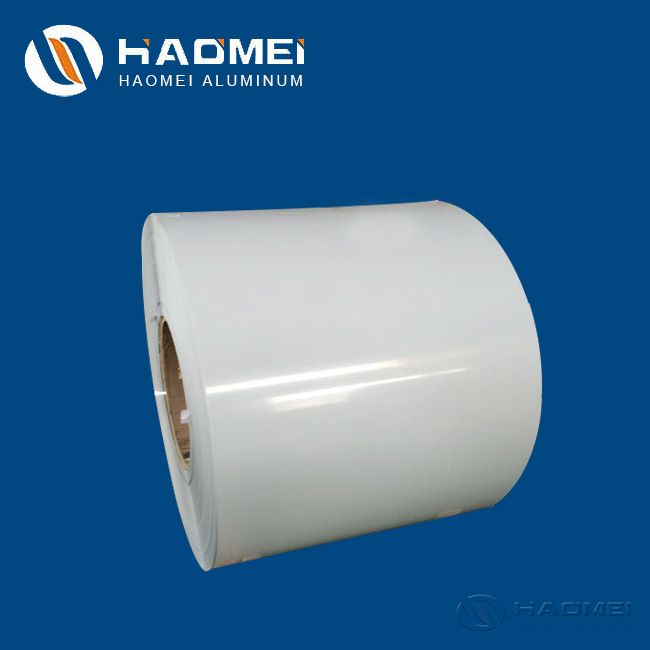

2. Color coating treatment

Process principle

Color coating treatment is to apply one or more layers of organic coating on the surface of aluminum coil, and solidify the coating through baking and other processes, so as to form a layer of color coating with protective and decorative functions on the surface of aluminum coil.

There are many kinds of coatings, and the common ones are polyester coatings, fluorocarbon coatings, etc. During the coating process, different colors and coating thicknesses can be selected according to user needs to achieve diverse appearance effects and performance requirements.

Features

Rich color selection: Color-coated aluminum coils have an extremely rich color system that can meet various design and decoration needs. This makes color-coated aluminum coils extremely flexible in color matching in the fields of architecture, home appliances, etc.

Good weather resistance: Aluminum coils that are color-coated with high-quality paint have excellent weather resistance and can maintain bright colors and intact coatings for a long time under different climatic conditions.

Excellent corrosion resistance: The coating can effectively isolate the surface of the aluminum coil from the external environment, prevent the aluminum coil from being oxidized and corroded, and extend its service life. In some humid and highly corrosive environments, such as chemical companies and buildings in coastal areas, the corrosion resistance of color-coated aluminum coils is particularly obvious, and can provide reliable protection for buildings and equipment.

Good processing performance: On the basis of maintaining the good processing performance of the aluminum coil, the color-coated aluminum coil has a strong combination of coating and aluminum coil substrate. In the subsequent processing, such as bending, stamping, cutting, etc., the coating is not easy to fall off or crack, which can meet the requirements of various complex processing technology and facilitate the production and manufacturing of products.

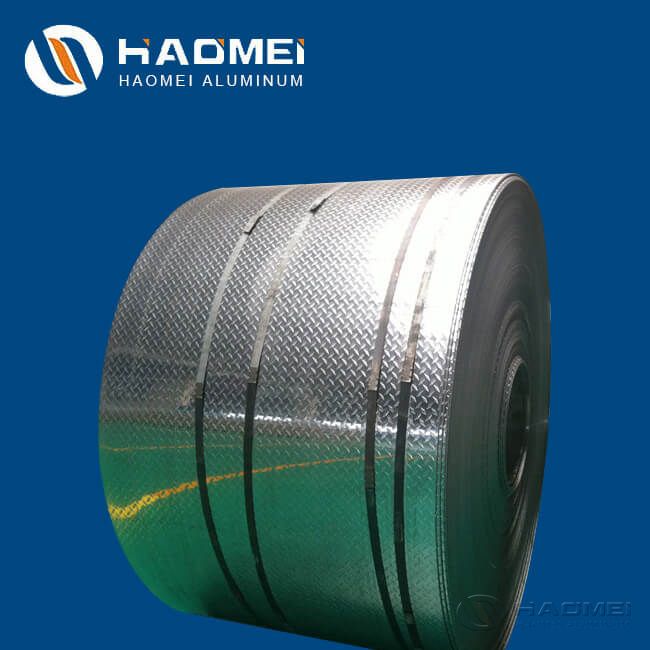

3. Embossing treatment

The embossed aluminium coil is to apply a certain pressure on the surface of the aluminum coil, and use an embossing roller with a specific pattern or pattern to make the surface of the aluminum coil plastically deform, thereby forming various exquisite patterns, designs or textures.

During the embossing process, the aluminum coil can also be subjected to subsequent treatments such as coloring and coating according to actual needs to further enrich its appearance and performance.

Features

Rich decorativeness: Embossed aluminum coils have rich and colorful patterns and designs, which can meet the personalized needs of different users for decorative effects. In the field of home decoration, embossed aluminum coils are used for furniture panels, interior decorative lines, etc., which can create a warm and comfortable living environment.

Enhanced mechanical properties: The embossing treatment changes the surface structure of the aluminum coil to a certain extent, improving its strength and rigidity. Compared with ordinary aluminum coils, embossed aluminum coils have better deformation resistance and can withstand greater external forces. In application scenarios such as building roofs and walls, embossed aluminum coils can better resist the erosion of natural factors such as wind and rain, and extend their service life.

Good anti-slip performance: some embossed aluminum coils with special textures, such as diamond pattern, orange peel pattern, etc., have greater surface friction and excellent anti-slip performance. This feature makes it widely used in places where anti-slip function is required, such as stair treads, ship decks, industrial plant floors, etc., effectively ensuring the safety of personnel and equipment.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China