What Are Anodized Aluminum Metal Colors

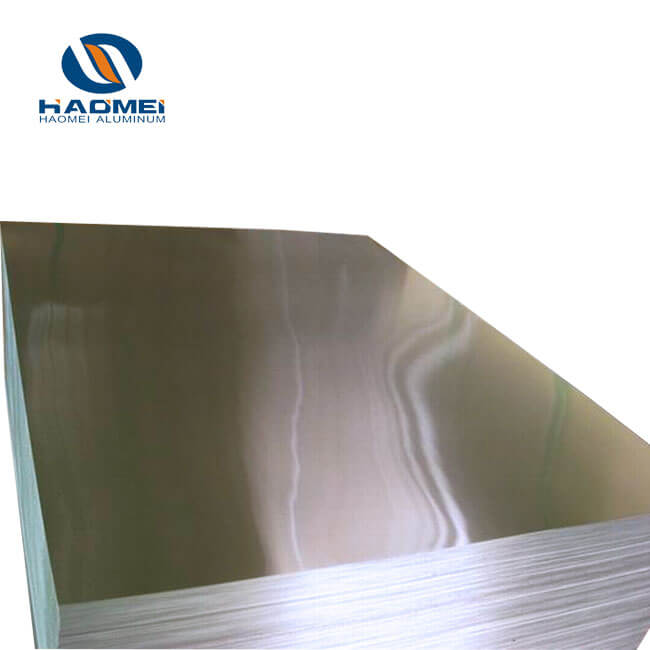

There are anodized aluminum colors like blue, red, green, black, etc. The anodized aluminum metal is widely used in many applications, such as lighting, kitchen supplies, home appliances,etc.

The anodizing process allows a variety of colors to appear on the aluminum surface, including blue, red, green, black, silver, gold, bronze, orange, purple, pink, and more. The anodized aluminum metal can be divided into several types according to the color and surface. The following are the three most representative ones.

White aluminum anodizing: It is the most common aluminum anodizing method. It does not appear white, but makes the appearance of the substrate slightly dull. The film thickness is about 10μm.

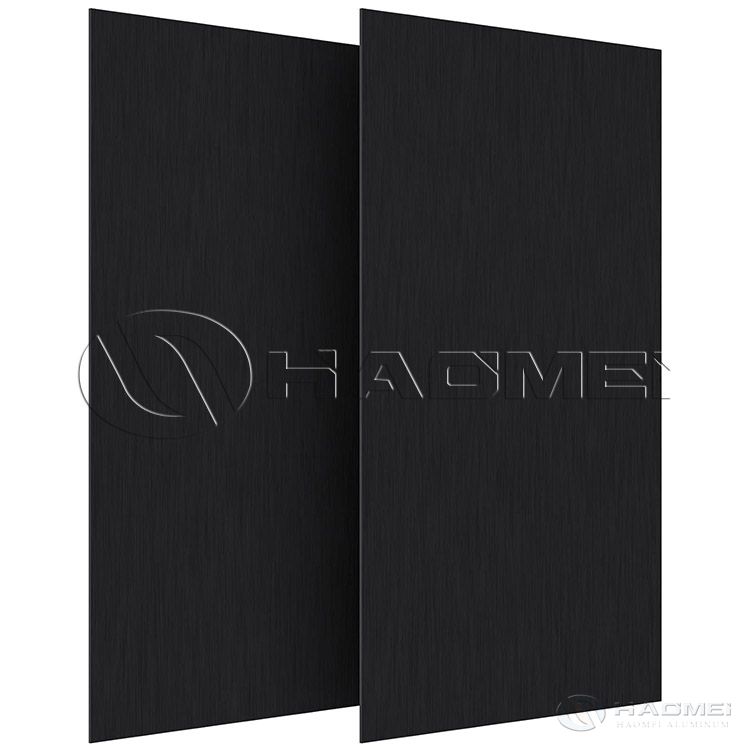

Black Aluminum Anodizing: Aluminum anodizing is dyed in different colors. Among them, the one dyed black is called black aluminum anodizing. It is the most commonly used color aluminum anodizing method.

Aluminum anodizing (matte): If the material is sandblasted before aluminum anodizing, a matte effect will be produced. It has a particularly high decorative effect in aluminum anodizing, and can be dyed not only white but also in a variety of colors.

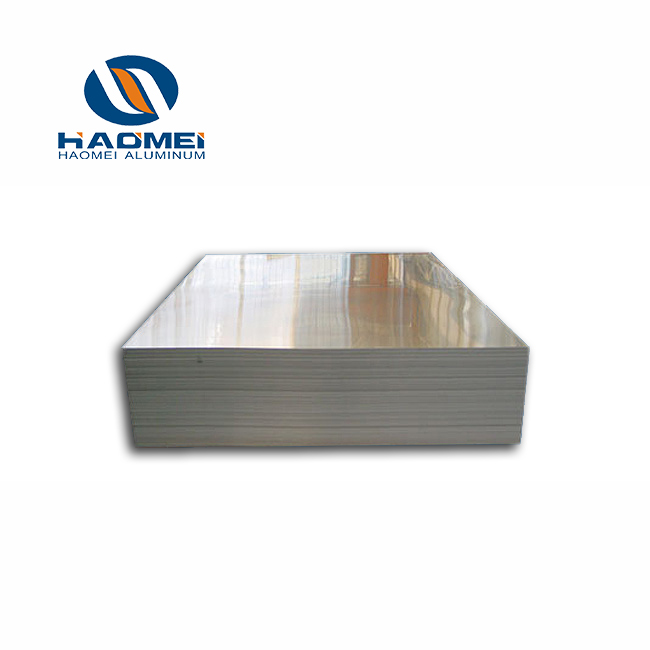

Uses of anodized aluminum sheets

Kitchen supplies such as food container, kettles and pots: anodized aluminum sheets with strong corrosion resistance, light weight and high scratch resistance are ery suitable for items that frequently come into contact with water around the kitchen.

Home appliance parts such as smartphones: Aluminum anodized sheets have a beautiful appearance and are not easy to damage, so they are also widely used in home appliance parts. Aluminum anodized materials with strong decorative properties can increase the added value of electronic products, so they are widely used.

Building materials such as window frames: Aluminum anodized plate with high corrosion resistance and high decorative properties are also often used for metal columns and window frames.

Interior parts of electrical vehicles and airplanes: In order to improve fuel economy and energy saving in transportation equipment, it is necessary to achieve lightweight. Therefore, aluminum parts that have been anodized are widely used.

Auto parts such as aluminum alloy wheels: Corrosion-resistant and wear-resistant aluminum anodized products are also very suitable for car wheels.

Optical components: The advantage of aluminum anodizing is that it is highly decorative and can be processed into various colors. Black aluminum anodizing materials that are not easy to reflect light are used around optical components.

Semiconductor components: Aluminum anodized products have high insulation and high heat dissipation. Therefore, aluminum anodized products are also widely used in components around semiconductors in electronic devices.

Lighting equipment such as LEDs: Lamps are the most likely electrical products to be highly creative. Aluminum anodized products not only have high decorative properties, but also have heat dissipation properties, so they are also widely used in lighting equipment.

Medical devices: Medical devices, which have high requirements for hygiene, must be scratch-resistant. Because scratched parts will accumulate dirt, which is the culprit for sanitary damage. Aluminum anodized products are light, scratch-resistant, and not easy to corrode, suitable for occasions with high hygiene requirements.

Nameplates and decorative panels: For parts such as decorative panels where customers require different colors, anodized aluminum is very suitable.

Haomei Alumimum has rich colors of anodized aluminum sheets. Which anodized aluminum color do you need? Welcome to tell us directly.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China