What Are Advantages of Aluminum Reflector Sheet for Lighting

The aluminium reflector sheet is mainly used lighting ,especially explosion-proof street lights due to excellent corrosion resistance and high reflectivity, helping to improve brightness and protect bulbs.

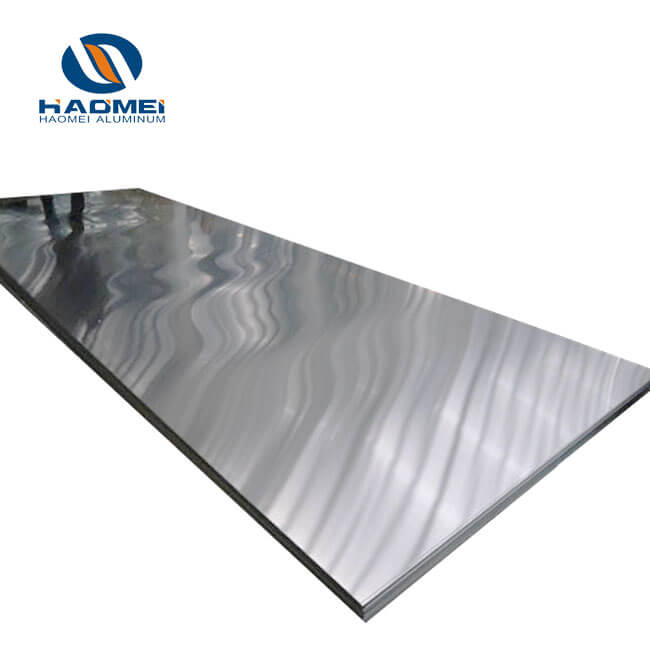

In daily life, mirror aluminum sheet is mainly used in lighting reflectors and lamp decorations, solar heat collection reflective materials, interior building decoration, exterior wall decoration, household appliance panels, electronic product shells, furniture kitchens, interior and exterior decoration of automobiles, signs, logos, jewelry boxes and other fields.

Explosion-proof street lights generally appear in flammable and explosive places where accidents are prone to occur. For example, roadside lighting in gas stations and chemical plants is the use of such explosion-proof street lights. Due to the special requirements of explosion-proof lamps, the requirements for its anti-corrosion performance are more stringent, and general materials cannot achieve this effect. At this time, reflective aluminum comes in handy.

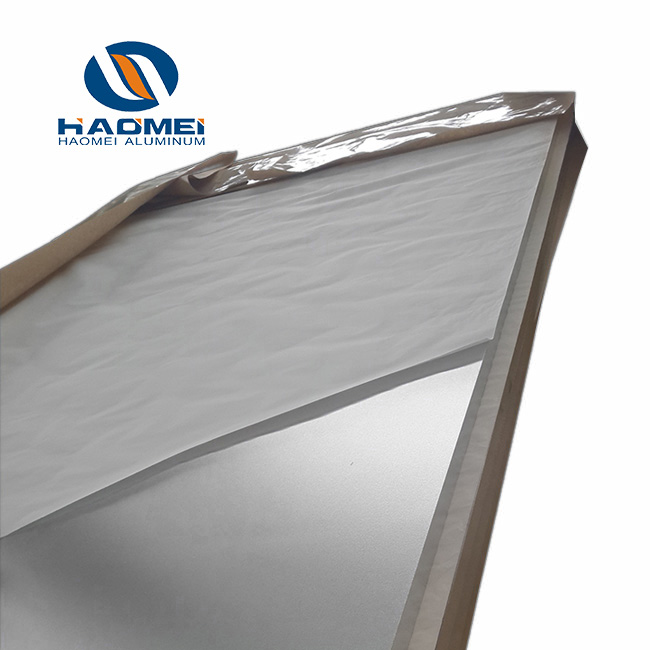

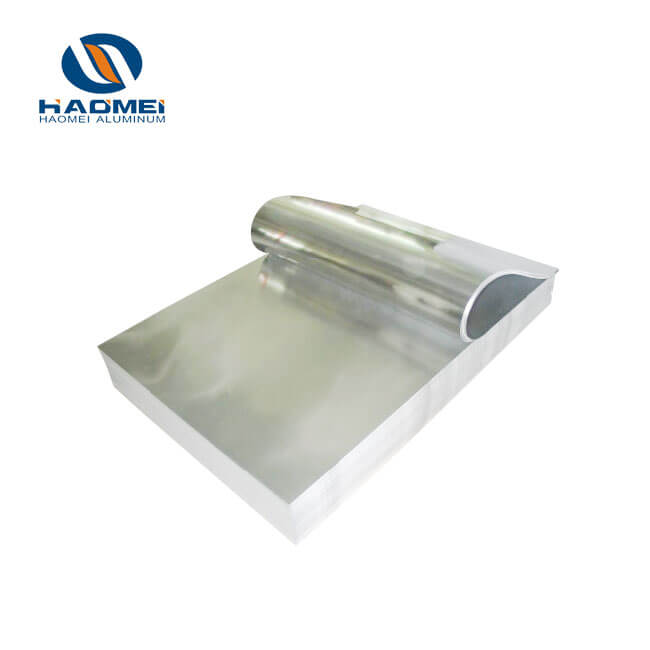

Mirror aluminum is a lightweight aluminum alloy material that is made into a mirror-like surface through a special process, and then undergoes anodic oxidation treatment, which can play a very good anti-corrosion function. Mirror aluminum can be used in various environments, with good anti-corrosion effect, high reliability and easy maintenance.

In addition, the mirror aluminum can also be used as a reflector to gather the light together to increase the brightness, which is obviously better than ordinary lighting. Another effect of mirror aluminum is to protect the light bulb. Due to its strong anti-corrosion function, it can significantly increase the service life of the light bulb. Compared with ordinary street lights, it significantly reduces the probability of the light bulb being damp and causing casualties. This is why explosion-proof lamps made of mirror aluminum are becoming more and more popular.

The widespread use of explosion-proof lamps is largely due to the contribution of polished aluminum sheet. Not only is the market for aluminum reflective sheet in explosion-proof street lamps growing, but the unique performance and product advantages will make mirror aluminum more and more widely used.

How to maintain mirror finish aluminum sheet? First of all, only proper cleaning can ensure the long-term work of the mirror aluminum plate. The surface of the mirror aluminum plate should be rinsed with plenty of water; secondly, gently scrub the surface with a soft cloth and diluted detergent and rinse off the detergent residue; finally, carefully check the surface of the mirror aluminum plate and clean again the stubborn stains.

The main difference of the aluminum mirror sheet is the reflectivity. The higher the reflectivity, the higher the technical requirements. Under normal circumstances, the reflective rate of aluminum reflector sheet in lamps is about 70%, and the high-end cosmetic packaging materials require a reflective rate close to 90%. Haomei Aluminum uses physical technology to replace traditional polishing technology, and the production process will not cause environmental pollution.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China