Polysurlyn Polykraft Laminated Aluminum Coil

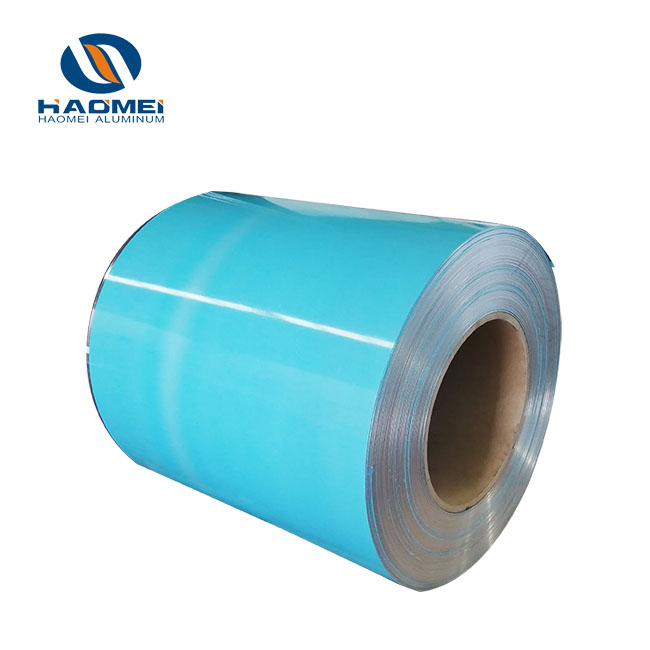

There are two popular thermal insulation aluminum coils: polysurlyn laminated aluminum coil and polykraft laminated aluminum coil. The alloys are 1060 and 3003. Learn more.

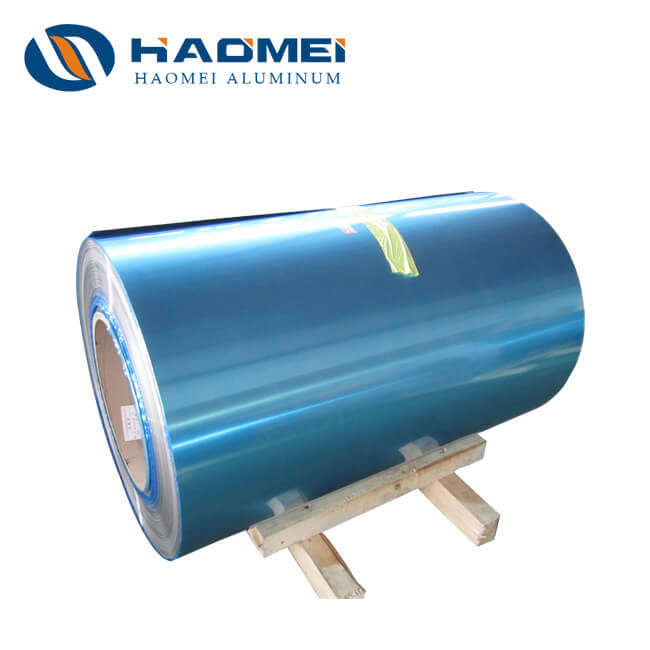

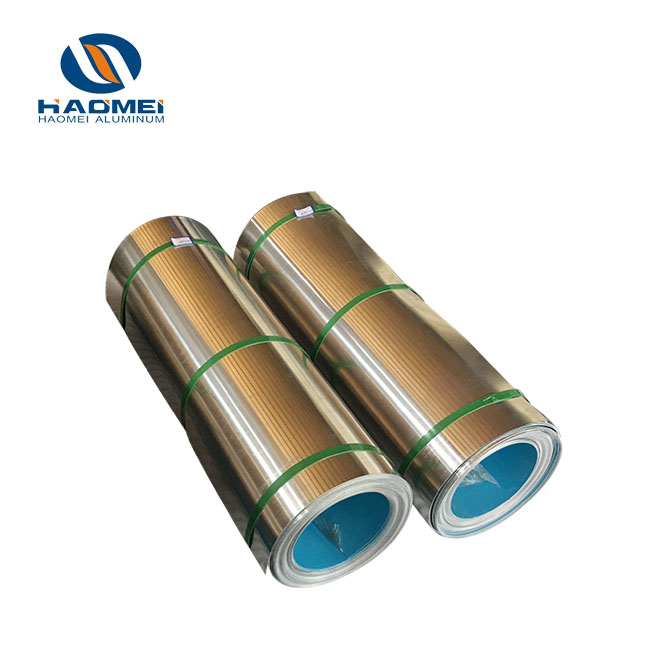

Polykraf laminated aluminum coil is also a product that has just emerged in recent years. Generally, foreign users, especially those in the Middle East, use it more. The thickness is generally 0.2-2.0mm and the width is between 800-1300mm. The alloy is generally made of 3003, 3004, 3104 or 5052,etc.

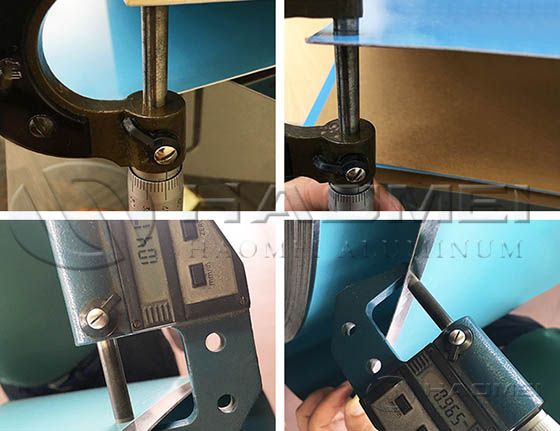

Aluminum coil with polysurlyn film is made by high-pressure hot pressing process to make the polymer film and aluminum coil fit tightly, which is an emerging raw material in the insulation industry. The thickness of polysurlyn film is 0.076mm, and the weight per square is 0.08 kg. After being attached to the aluminum coil, it will not crack and cannot be torn off by hand. It absorbs 0.5 grams of water vapor per square per day. It has stronger waterproof advantages than color-coated plates and kraft paper.

Aluminum with polysurlyn film can be effectively used in the anti-corrosion projects like oil refineries, power plants, chemical plants, etc. This aluminum coil has excellent adhesion, very good air tightness, and excellent anti-corrosion performance, making it an ideal material for the anti-corrosion protective layer of the pipeline.

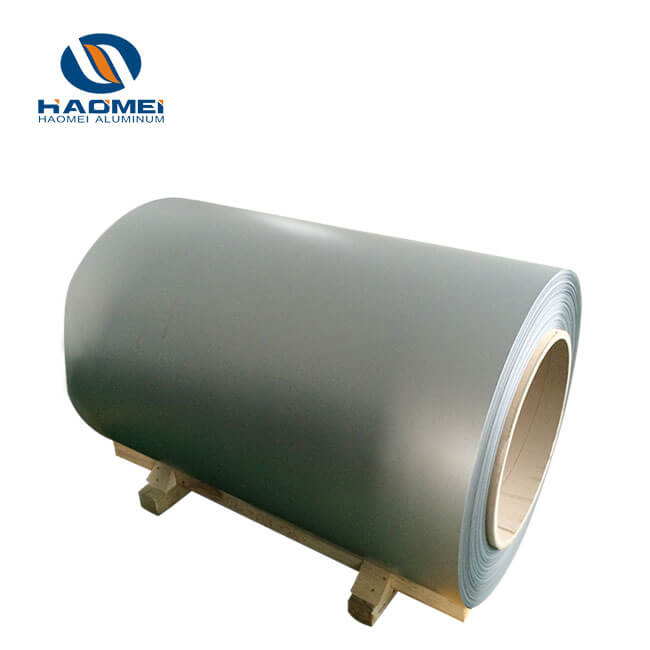

Now the thickness of the Polysurlyn laminated aluminum coil used as the outer protective plate for pipeline insulation and anti-corrosion insulation work ranges from 0.1-1.0mm. Of course, the thickness is selected according to the diameter of the pipeline. The principle is that the smaller the diameter, the thinner the thickness. Generally, 1060 alloy is used more, accounting for 70% of the construction volume, and 30% of customers choose 3003 alloy.

1060 aluminum coil is industrial pure aluminum, with a relatively simple production process, mature technology, and a huge price advantage over other high-end insulation materials. In addition, 1060 aluminum coil has good corrosion resistance, good thermal conductivity, good elongation and tensile strength, and high formability.

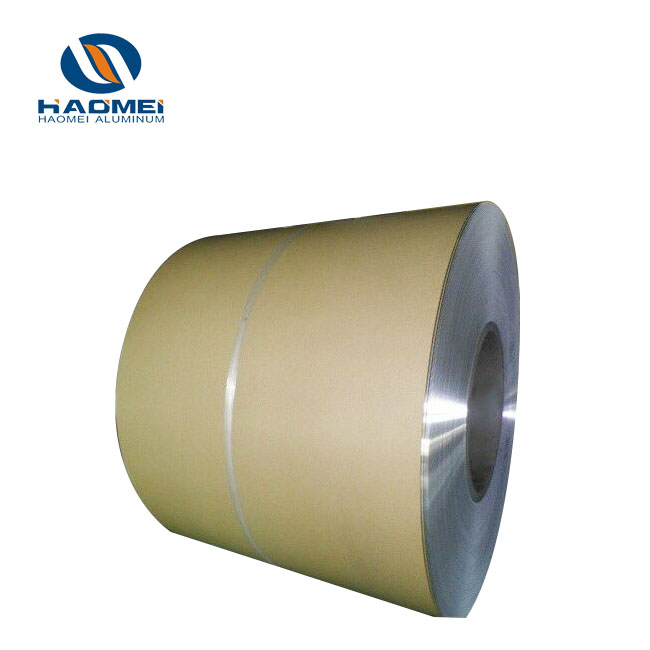

During construction, the thermal insulation aluminum coil cannot be used up all at once and needs to be properly stored. The thermal insulation aluminum coil needs to be waterproof, moisture-proof, rain-proof, and snow-proof. If the thermal insulation aluminum coil is not placed in a dry warehouse, once it rains, the acidic substances in the rain will cause the thermal insulation aluminum coil to oxidize. The oxidized thermal insulation aluminum coil basically becomes scrap aluminum, which is a major loss for the construction party, so the storage of the thermal insulation aluminum coil should be paid more attention.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China