How to Test Quality of Anti Slip Alloy Plates

The anti slip alloy plates are a patterned aluminum plate with various concave and convex patterns on the surface of the aluminum plate. How to test its quality? It includes six aspects like appearance. Learn more.

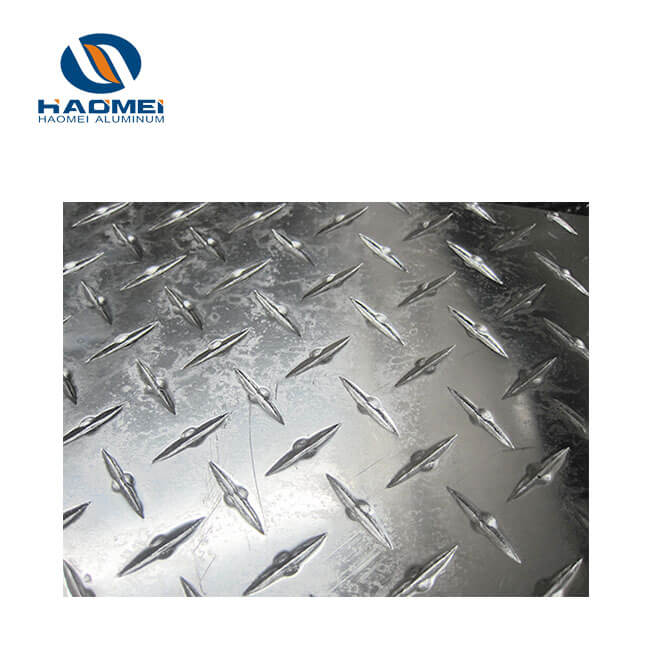

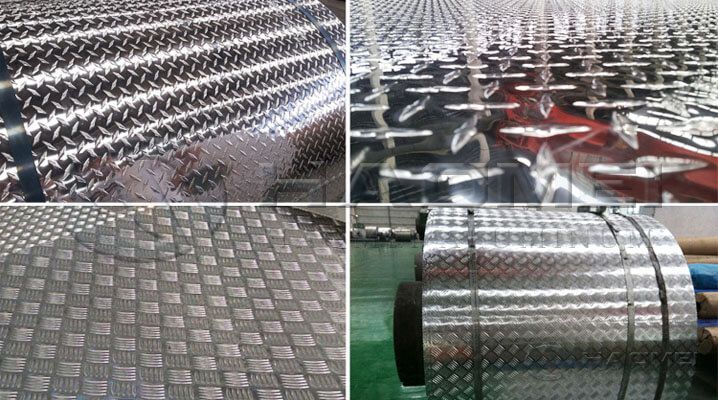

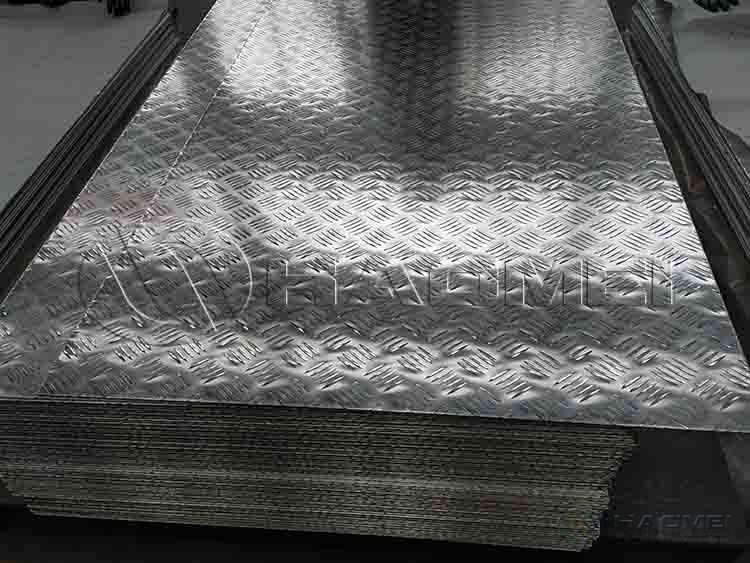

The anti slip alloy plates are a patterned aluminum plate with various concave and convex patterns on the surface of the aluminum plate, which has an anti-skid effect. It is used for the anti-skid aluminum plates on the ground, vehicles, ships, integrated houses, refrigerated trucks, cold storage, work platforms, foot pedals and other aspects. However, due to the influence of its production process and raw materials, the quality of aluminum checker plate is particularly important.

Inspection items of aluminum diamond plate

1. Chemical composition: By analyzing the chemical composition of the 5bar aluminum tread plate, determine whether its composition content meets the standard requirements.

2. Mechanical property: Conduct tensile, impact, bending and other tests on the aluminum diamond tread plate to measure its tensile strength, yield strength, elongation and other mechanical properties.

3. Metallographic structure analysis: Observe the metallographic structure of the aluminum diamond plate, and analyze its microstructural characteristics such as grain size, inclusions, and carbides.

4. Hardness test: Use a hardness tester to test the hardness of the 5 bar aluminum checker plate to understand its hardness distribution and uniformity.

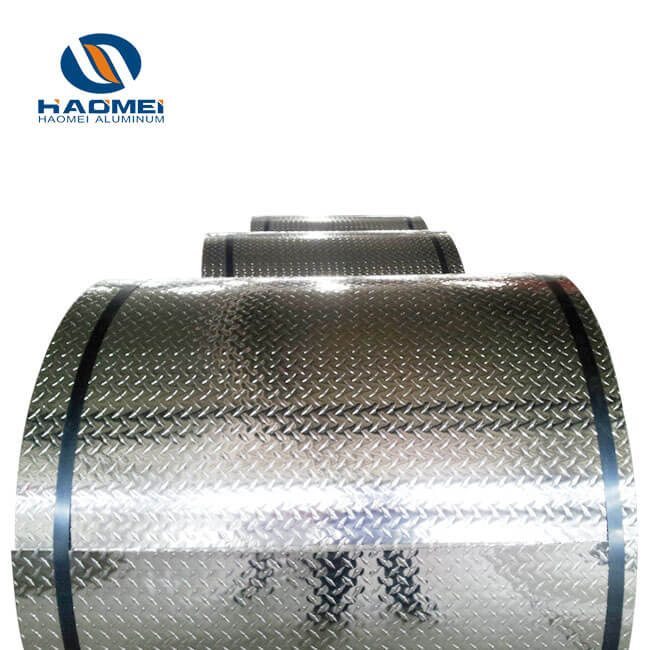

5. Appearance inspection: Visually inspect the surface of the pattern plate roll to check whether there are cracks, inclusions, pores and other defects.

6. Dimensional inspection: Measure the dimensions of the aluminum tread plate, including thickness, width, length and other parameters to ensure that it meets the standard requirements.

Testing methods

1. Appearance inspection. The main purpose is to check whether the surface of the aluminum tread plate is flat, whether the pattern is clear and whether whether there are scratches, bubbles and other defects on the surface. The detection methods include visual inspection and microscopic inspection.

2. Thickness detection. Generally, a thickness meter is used for measurement, and multi-point detection is required, the average value is calculated, and the qualification is judged within the allowable error range.

3. Chemical composition testing. Spectral analysis or chemical analysis is generally used for detection. The detection of samples requires attention to the sample quantity and sample representativeness.

4. Mechanical performance testing. Universal testing machines are generally used for tensile tests and impact tests, and must be operated in accordance with corresponding standards to ensure that the test results are accurate and reliable.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China