How Is Mirror Finished Aluminum Sheet Produced

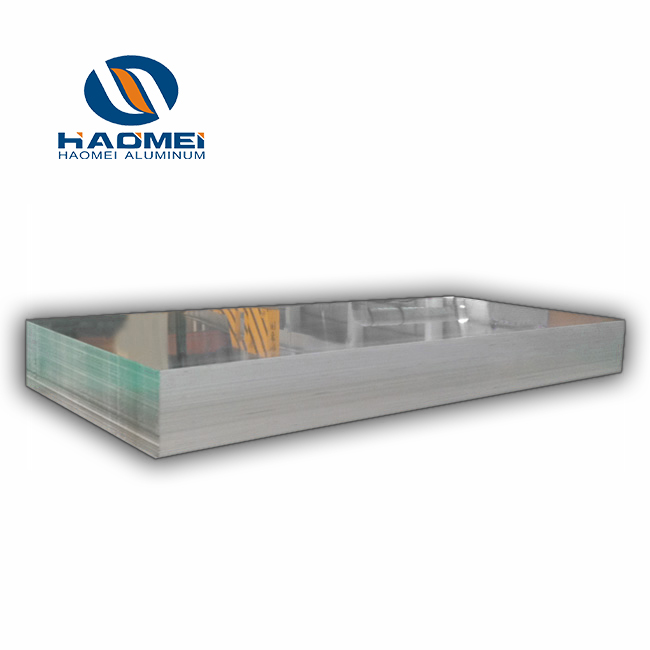

The mirror polished aluminum sheet is suitable for lighting, decoration, construction, etc. It is processed by repeated calendering of aluminum coils through mirror rollers. Welcome to inquire mirror finish aluminum sheet price from us.

The high reflective mirror polished aluminium sheet is suitable for lighting, decoration, construction, solar energy, electrical and electronic industries, etc. The reflective rate can reach more than 80-95%. It can be divided into standard mirror, high mirror and super mirror aluminum sheet according to the mirror surface. According to the post-processing method of the surface, it can be divided into an anodized aluminum mirror sheet and mirror aluminum sheet.

The mirror aluminum plate is got through various methods like rolling and grinding to make the surface of the aluminum plate show a mirror effect. It has the following characteristics:

1. Hardness: It is of uniform thickness and good corrosion resistance, which is suitable for complex stamping, bending, stretching, shaping,etc.

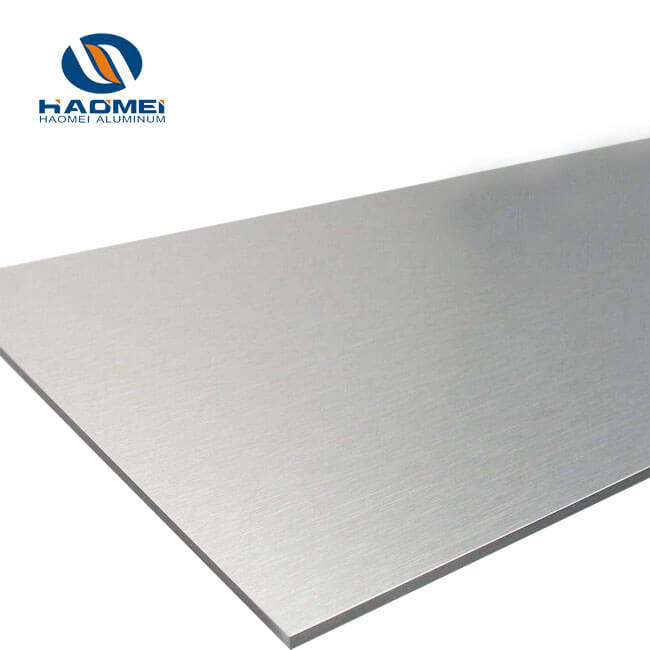

2. Surface treatment: It is suitable for high requirements and stable anodic oxidation surface treatment, such as chemical polishing, atomization, chemical sanding, electropolishing, dyeing, sealing and other processing.

3. Mirror surface characteristics: The mirror surface of this material is produced by mechanical polishing. There is no electroplating coating on the surface. Before spraying and anodizing, there is no need to remove the anode or electroplating film.

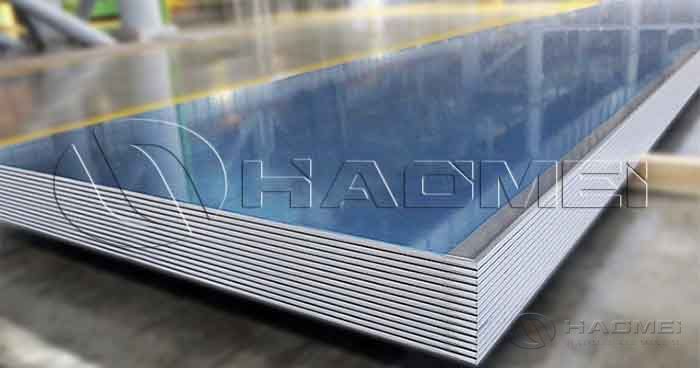

Usually, the mirror aluminum plate is processed by repeated calendering of aluminum coils through mirror rollers, so that the surface of the aluminum coil or aluminum plate presents a mirror effect. The reflectance of the aluminum mirror sheet is closely related to the roll and the rolling mill. It can be said that the roll grinding process and the mirror surface of the rolling mill determine the reflectivity of the mirror aluminum plate.

There is another production process, that is, the aluminum plate is used as the base material to compound a mirror-like film on it. The mirror finish aluminum sheet can be further processed like anodizing or coating, then we get the anodized aluminum sheet or color coated aluminum mirror sheet.

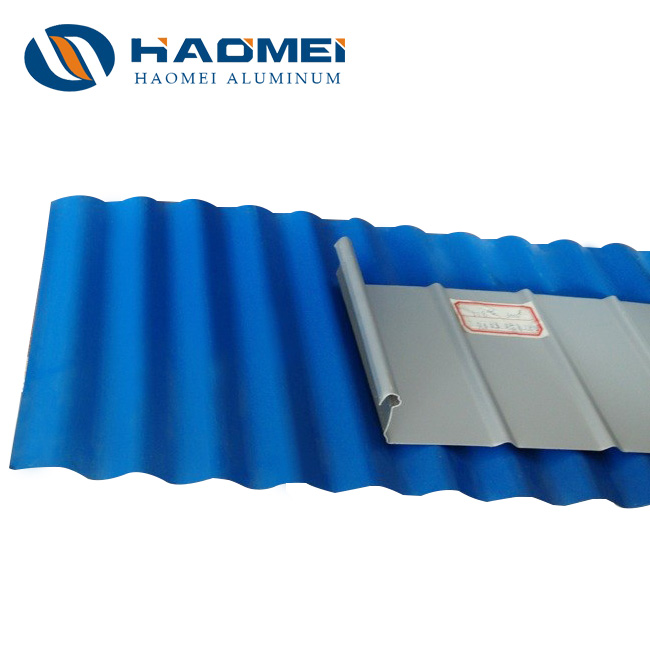

After the aluminum coil has been calendered and polished, it is then placed on the slitting equipment for filming and slitting. It should be noted that blue or yellow protective film or electrostatic protective film is generally used for mirror finished aluminum sheet. There should be no glue on the protective film, otherwise it will affect the reflectivity after a long time, and then the mirror aluminum roll can be packed or cut to size. Welcome to leave message below to inquire the mirror finish aluminum sheet price.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China