High Quality Color Coated 1100 3003 Aluminium

The performance differences in the coated aluminum stem from the alloy composition. 1100 aluminum falls into the category of industrial pure aluminum, with an aluminum content exceeding 99% and virtually no other alloying elements. This hig

The performance differences in the coated aluminum stem from the alloy composition. 1100 aluminum falls into the category of industrial pure aluminum, with an aluminum content exceeding 99% and virtually no other alloying elements. This high purity endows it with unique softness.

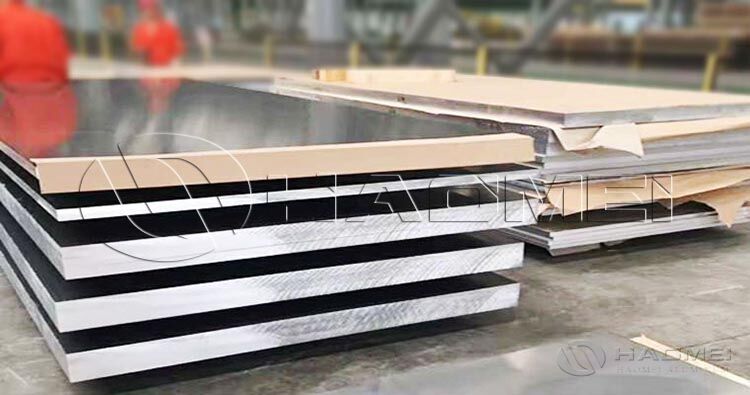

3003 aluminum sheet , on the other hand, is a typical aluminum-manganese alloy. In addition to its 98% aluminum content, it contains 1.0%-1.5% manganese. It is this manganese that allows it to surpass 1100 in strength, making it a preferred choice that balances performance and cost.

This difference in composition directly manifests in key performance indicators: 1100 alloy has a tensile strength between 60-110 MPa, classifying it as a typical soft aluminum material; 3003 alloy , however, has a tensile strength of 120-178 MPa while maintaining its lightweight characteristic of 2.73 g/cm³, with a density only one-third that of steel.

In terms of corrosion resistance, both perform exceptionally well. 1100 aluminum coil , due to its higher purity, has a slight edge, while 3003 aluminum, thanks to the dense oxide film formed by manganese, boasts corrosion resistance approaching that of pure aluminum, sufficient for most everyday environments.

Colored aluminum 1100

Due to its high purity and low impurity content, 1100 aluminum exhibits excellent ductility. Its elongation in the annealed state far exceeds that of ordinary aluminum, easily enabling complex forming processes such as deep drawing, bending, and stretching. Even when processed into intricately curved decorative pieces, it is not prone to cracking. This characteristic makes it an ideal choice for scenarios requiring delicate shapes.

In terms of surface treatment compatibility, 1100 also performs excellently. Polyester coatings adhere evenly to its surface, resulting in vibrant colors that are resistant to peeling. Its high electrical conductivity also makes it suitable for some specialized fields, but its most outstanding feature is its corrosion resistance; it is not prone to rusting in humid or mildly acidic/alkaline environments.

In the field of interior decoration, 1100 color aluminum, with its excellent formability and color performance, has become the preferred material for ceilings, partitions, and decorative walls. In the food industry, it is commonly used to manufacture food storage tanks and pipelines; its high purity and corrosion resistance ensure food safety.

Colored aluminum 3003

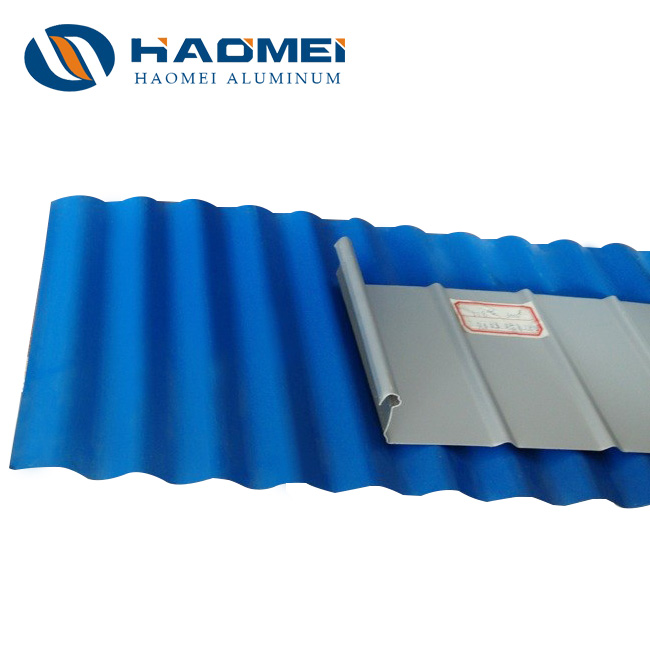

The addition of manganese to 3003 color coated aluminum creates a perfect balance between strength and processability. While its strength is not as high as high-strength aluminum alloys, it is about 10% higher than 1100, sufficient to meet the wind load requirements of outdoor construction. It also retains good formability, allowing it to be pressed into various shapes such as corrugated sheets and sandwich panels, adapting to different construction scenarios.

Weather resistance is another major highlight of 3003. After fluorocarbon (PVDF) coating treatment, it can resist ultraviolet radiation and acid rain corrosion, with a service life of over 15 years, fully meeting the long-term use requirements of outdoor construction.

Its weldability is also excellent, suitable for both argon arc welding and resistance welding. The welded joints have high strength and corrosion resistance close to that of the base material, giving it a significant advantage in large-scale projects requiring splicing.

The construction industry is the main battleground for 3003 aluminum alloys, especially in the outdoor sector. Many industrial plant roofs and stadium facades are constructed using 3003 aluminum alloy.

In the new energy sector, 3003 aluminum sheet is also making its mark. Photovoltaic power plant supports and distributed photovoltaic backsheets often use 3003 aluminum alloy as the base material. Its high weather-resistant polyester coating allows it to adapt to harsh environments such as deserts and coastal areas, while its lightweight advantage reduces transportation and installation costs.

In the home furnishing sector, it is used to manufacture kitchenware and wardrobe sliding doors; its strength is sufficient to withstand daily wear and tear, and its customizable colors can match different decorating styles.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China