Different Types of Marine Aluminum for Boat

Aluminum alloys have been used in the shipbuilding industry for nearly a hundred years. Aluminum alloys can be used as aluminum plates, or they can be extruded and cast. The processing cost of aluminum is low, and the outstanding physical properties of marine grade aluminium alloys make it more economical to manufacture ships with aluminum alloys.

Different types of marine grade aluminum

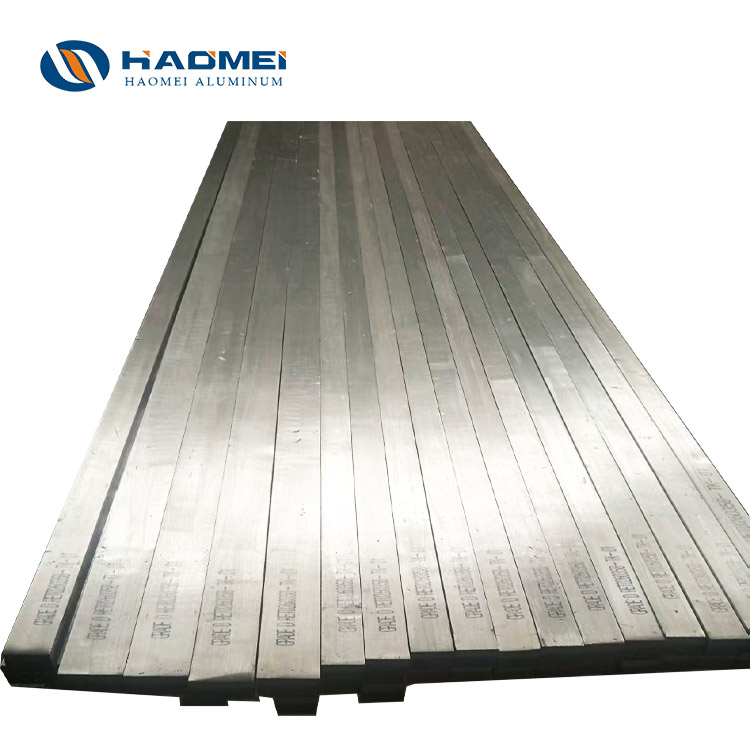

Aluminum alloy profiles

Aluminum alloy profiles play a key role in shipbuilding. In the superstructure of ships, 6063 aluminum alloy is a commonly used profile material for portholes. Its good corrosion resistance and processing performance can ensure the long-term stable use of portholes in the marine environment, and it is easy to process into various shapes to meet design requirements.

Some ships' sidings use extruded aluminum-magnesium alloy profiles, which can prevent deformation during welding while ensuring a more reasonable stress distribution, effectively improving the stability of the ship structure.

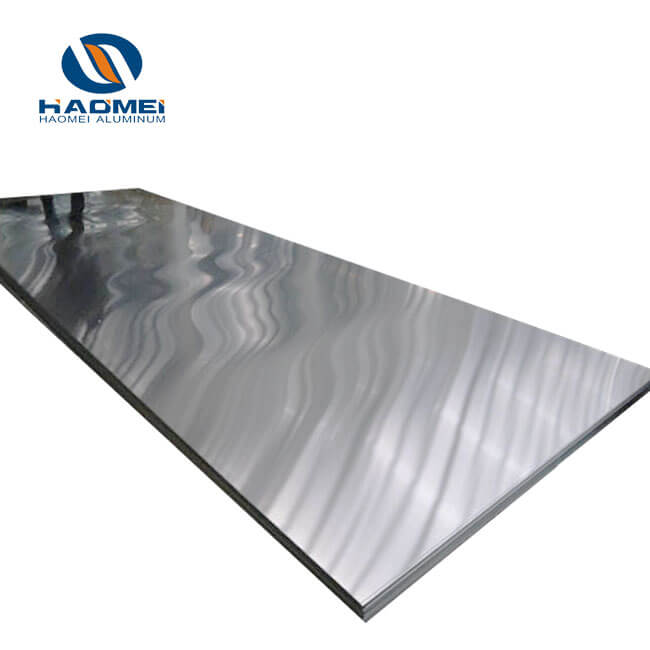

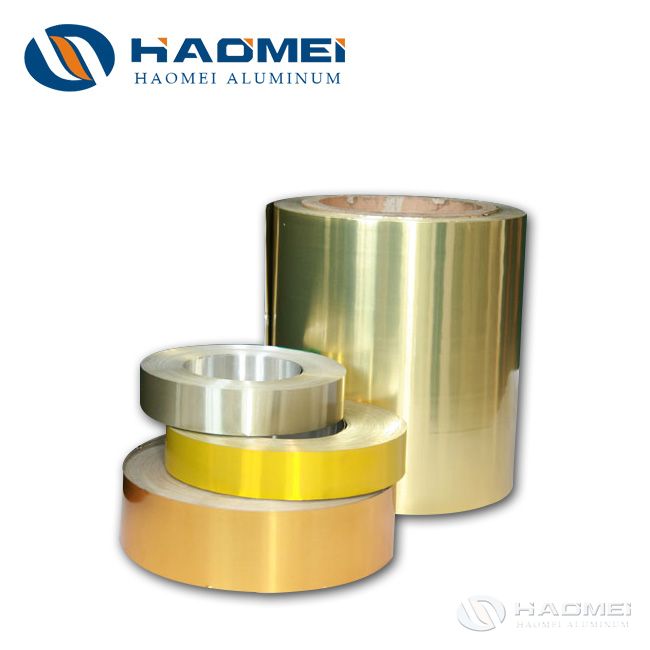

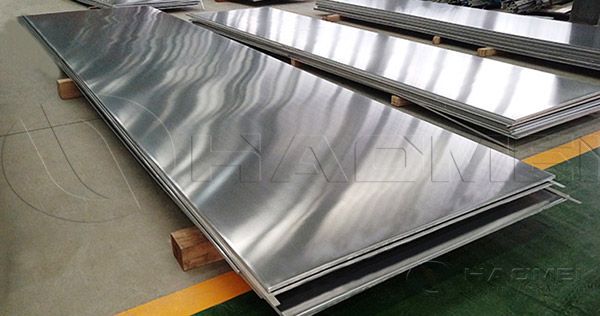

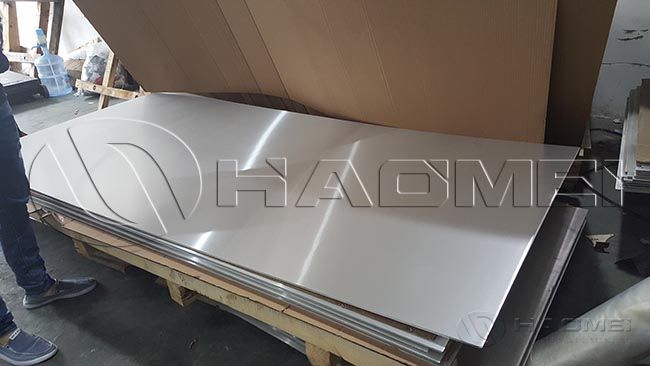

Aluminum plate

Aluminum plate is an important component of marine aluminum alloy. Marine aluminum plates usually use aluminum alloys such as 5083 and 5086. These aluminum alloys have good plasticity, strength and corrosion resistance, and can meet the requirements of shipbuilding.

5083 marine aluminum sheet is widely used in hull structures, such as the bottom outer plate, keel, ribs and other parts. Its high strength and excellent seawater corrosion resistance can effectively resist seawater erosion and mechanical impact and ensure the safety of the hull. 5086 aluminum plate is often used for structures with high weight requirements and certain strength, such as the hull shell of some small high-speed ships. It can reduce the weight of the hull while ensuring that the ship has sufficient strength and rigidity.

The thickness of marine aluminum plate is usually between 3-500mm. The appropriate thickness is selected according to different parts and uses. From the perspective of lightweight hull, thin plates are generally used as much as possible, but the depth of plate corrosion during use should also be considered.

Aluminum pipe fitting

Marine aluminum alloy pipe fittings are mainly used in various pipe systems of ships, including seawater cooling systems, fuel delivery systems, fresh water supply systems, etc. In seawater cooling systems, aluminum alloy pipe fittings need to have excellent seawater corrosion resistance to ensure the long-term stable operation of the system.

Some aluminum alloy pipe fittings use special alloy formulas and surface treatment processes to effectively resist the erosion of chloride ions in seawater and prevent pitting and corrosion. In the fuel delivery system, pipe fittings need to have good sealing performance and strength.

Aluminum alloys can meet these requirements, and their lighter weight also helps to reduce the overall weight of the ship. The processing accuracy and quality of aluminum alloy pipe fittings directly affect the operating efficiency and safety of the pipe system. Therefore, the processing technology and quality inspection need to be strictly controlled during the production process.

Main classification society certifications for marine aluminum alloys

Classification society certification is an important recognition of the quality and safety of marine aluminum alloys. Internationally, major classification societies such as ABS (American Bureau of Shipping), BV (Bureau Veritas), LR (Lloyd's Register), DNV, etc., have established strict certification standards for marine aluminum alloys.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China