Aluminum Sheet For Facade

Answers to hot questions about aluminum sheet for facade: alloy choice, thickness, PVDF/anodized finishes, durability, corrosion, and cost drivers.

Modern buildings often use aluminum sheet for facade cladding because its lightweight, corrosion-resistant, and easy to fabricate into flat panels, folded cassettes, and rainscreen systems. On Google and Quora, new buyers repeatedly ask the same practical questionsusually right before they request quotes.

Below are 5 of the most common real buyer questions, with straightforward answers focused on what to specify (and what to avoid) when sourcing facade aluminum.

1) Which aluminum alloy is best for facade panels: 3003, 5052, or 6061?

Why people ask it: Facade panels must stay flat, resist dents, and survive outdoor corrosionyet they also need to bend cleanly at edges.

Practical answer:

- 3003 is widely used for cladding and general sheet metal work because it forms easily and offers good corrosion resistance. Its often selected when you need smooth bending and economical pricing.

- 5052 is a common upgrade choice when buyers worry about coastal exposure, chemical atmosphere, or higher strength needs. It has stronger mechanical properties than 3003 and very good corrosion resistance.

- 6061 is strong and popular in structural parts, but its not always the best first choice for thin facade skins if heavy forming is required. It can be less forgiving in tight-radius bends compared to softer cladding-friendly options.

If you are unsure, many buyers start with 3003 for standard urban projects and move to 5052 for harsher environments or higher dent resistance. For product selection and baseline specs, see 3003 Aluminum Sheet/Plate Metal and 5052 Aluminum Sheet/Plate.

2) What thickness of aluminum sheet is used for facade cladding?

Why people ask it: Thickness affects flatness, oil-canning risk, wind load performance, and cost.

Practical answer: Most facade sheets fall into a small set of buying ranges, but the right number depends on panel size, stiffeners, and mounting system.

| Typical Use Case | Common Thickness Range | Notes Buyers Miss |

|---|---|---|

| Small folded trims, flashings, reveals | 0.81.5 mm | Easy to form; can dent if exposed at pedestrian level |

| Cassette-style panels / rainscreen skins | 1.53.0 mm | Often needs proper stiffening to control oil-canning |

| Larger panels, higher wind zones, impact-prone areas | 2.54.0 mm | Weight increases fast; design matters as much as thickness |

Two buyer tips that prevent regrets:

- Dont specify thickness alone. Ask your fabricator how they control flatness (stiffeners, returns, cassette depth).

- Confirm tolerance and temper. Two sheets at 2.0 mm can behave differently if tolerances and temper are not aligned with forming requirements.

3) PVDF vs powder coating vs anodizingwhat finish lasts longest on a facade?

Why people ask it: Color fading and chalking show up quickly on sun-exposed elevations, and repainting a facade is disruptive and expensive.

Practical answer:

- PVDF coating is often chosen for exterior architectural facades because it offers excellent UV stability and weathering resistance. Its a common spec for premium commercial projects.

- Powder coating can look great and is widely available, but outdoor longevity depends heavily on resin type, coating thickness, and applicator quality. It can be a strong choice when the coating line is certified and the project environment is moderate.

- Anodizing creates a hard oxide layer and a metallic look. It performs well, but color uniformity can vary between lots, and matching repairs can be challenging. Its popular when a natural metal aesthetic is desired.

What to ask in a quote (simple but powerful):

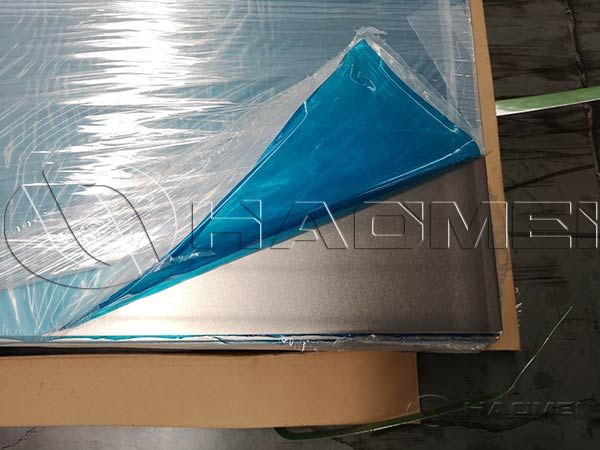

- Coating system type (PVDF / powder / anodized)

- Warranty expectation (color + film integrity)

- Pretreatment method (critical for adhesion)

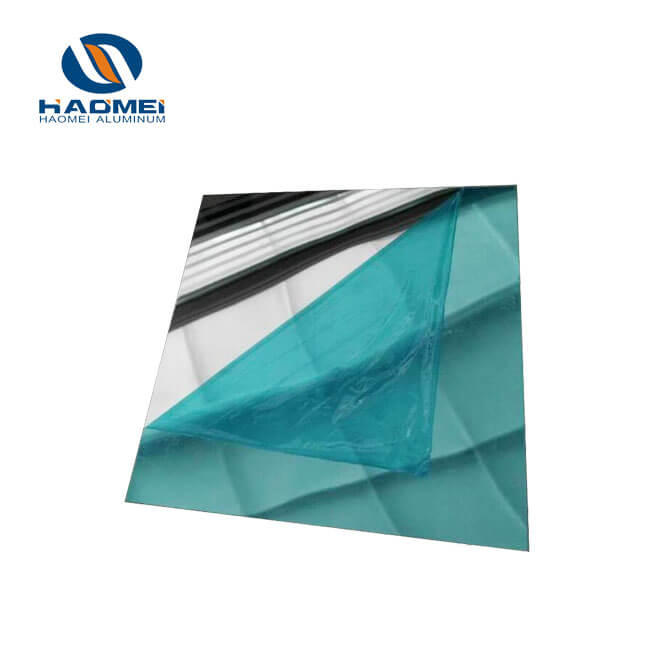

- Whether protective film is applied for fabrication and installation

4) Will aluminum facade sheets corrode? What about coastal buildings and galvanic corrosion?

Why people ask it: Buyers hear aluminum doesnt rust, then see stains or pitting on poorly designed systems.

Practical answer: Aluminum is corrosion-resistant, but facades can still fail if detailing is wrong.

Main risks and how buyers prevent them:

- Coastal salt exposure: Choose a corrosion-resistant alloy (often 5052) and a proven exterior finish. Ensure edges and cut surfaces are handled correctly.

- Galvanic corrosion (mixed metals): If aluminum touches copper, carbon steel, or some stainless grades in a wet environment, the aluminum can corrode faster. Use isolation pads/tapes, compatible fasteners, and proper drainage.

- Trapped water behind panels: Rainscreen design must ventilate and drain; standing water accelerates staining and corrosion.

Buyer checklist for harsh environments:

- Confirm alloy and temper

- Specify compatible fasteners

- Require isolation between dissimilar metals

- Ensure drainage/weep paths in the system design

5) What drives the price of aluminum sheet for facade, and how do I compare quotes?

Why people ask it: Two offers can look similar but differ in alloy, coating quality, tolerances, packaging, and yield loss.

Practical answer: The biggest cost drivers usually are:

- Alloy and temper (strength/forming requirements)

- Thickness and panel size (large sheets increase handling and flatness control costs)

- Surface finish system (PVDF and high-end anodizing typically cost more than standard powder)

- Protective film + surface standard (architectural visible surfaces need stricter inspection)

- Cut-to-size and fabrication readiness (leveling, tight tolerances, edge condition)

- Packaging and damage control (essential for long-distance delivery)

A quick way to compare quotes fairly is to request a shared spec table from all suppliers.

| Quote Item to Align | Why It Matters | What to Write in Your RFQ |

|---|---|---|

| Alloy/temper | Changes bendability and dent resistance | Specify alloy + temper for facade forming |

| Thickness tolerance | Affects flatness and fitting | State thickness tolerance and flatness method |

| Finish system | Determines UV durability | PVDF/powder/anodized with stated warranty target |

| Film + packaging | Prevents transit scratches | Protective film + export-grade packaging |

A simple buyer takeaway

If youre buying aluminum sheet for facade cladding for the first time, focus on (1) the right alloy for forming and environment, (2) thickness matched to panel design, and (3) a finish system proven outdoors. Most bad facade sheet problems come from vague specificationsso tightening the spec sheet usually saves money, even if the unit price looks slightly higher.

If youre preparing a request for quotation, include: alloy/temper, thickness, finish type, gloss/color, sheet size, tolerance needs, protective film, and packaging requirements. Thats the fastest way to get comparable offers and avoid surprises during fabrication and installation.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China