Aluminium Mirror Sheet for Grille Light and Reflector

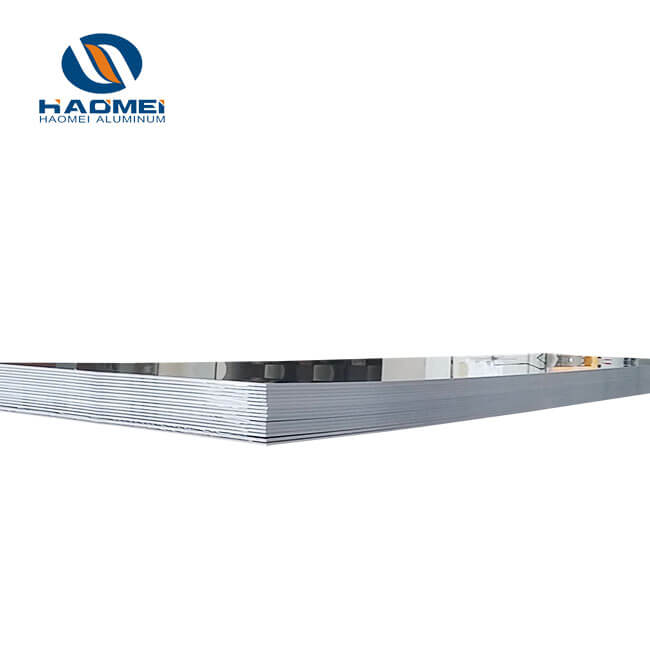

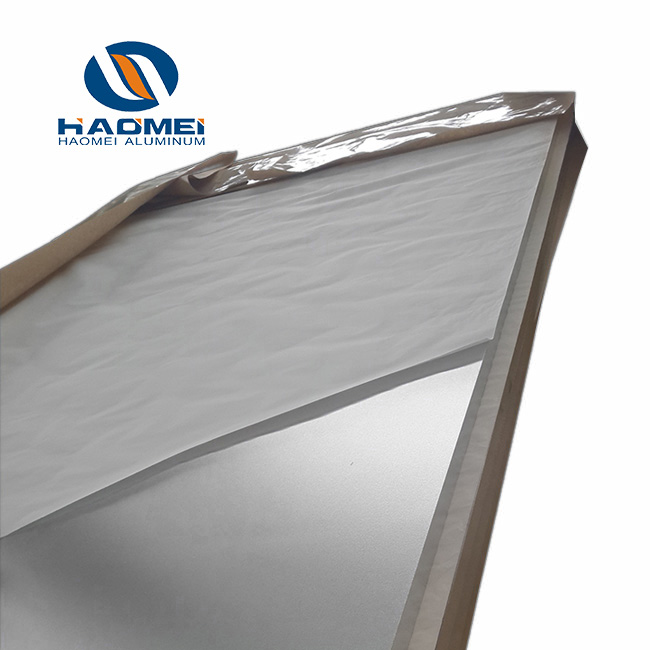

The aluminum mirror sheet is mainly used for the grille light and reflector. Haomei mirror finish aluminum sheet can reach a reflectivity of 86%. Learn more.

The grille light is a kind of lighting fixture, which is rarely used in the home. The grille lamp is mainly installed in the office building with a ceiling. There are two types of embedded and ceiling type.

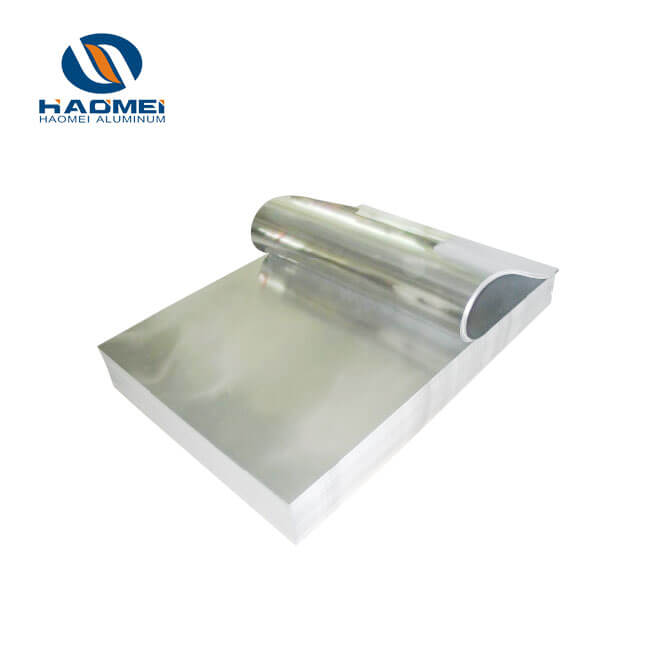

Traditional grille light sources are fluorescent tubes, but now LED grille lights are used. The new LED grille lights are mainly made of aluminium mirror sheet and with LED patches. The good heat conduction of aluminium mirror sheet is fully utilized, which makes LED grille light suitable for ong-term, large-area indoor lighting.

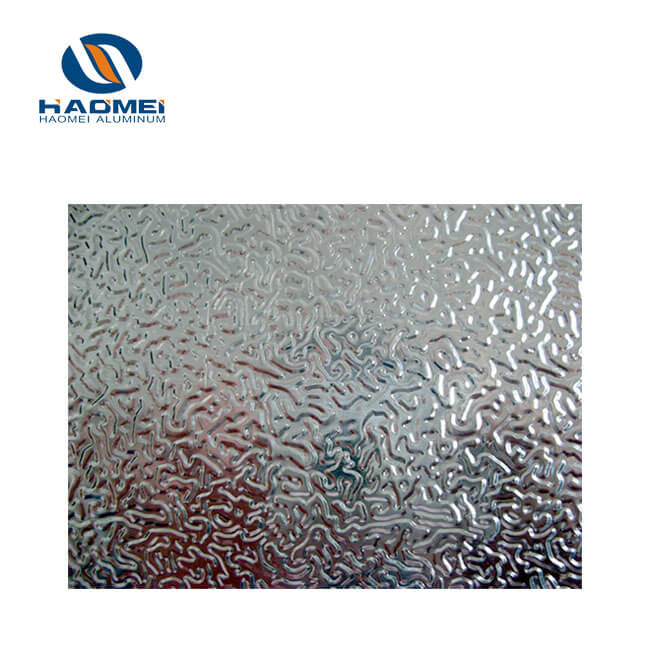

Reflector refers to a kind of reflector that reflects the light emitted by the light source that cannot shine on the working and living surfaces during the use of the lamp. The main reflective materials are aluminum mirror sheet, PVC lattice reflectors, electroplating, nano-film, fluorescent cloth, etc., which are widely used in reflectors and other aspects.

In 2006, Japan's Taketa Company first adopted a W-shaped reflector made of mirrored aluminum with a reflectivity of 86%, which increased the utilization rate of daylight to 85% for the first time. The reflectance of Haomei mirror finish aluminum sheet is as high as 86%. We also successfully developed the mirror aluminum anti-oxidation coating.

The production process of is more environmentally friendly, and the colors are bright and diverse. Haomei mirror finish aluminum sheet is widely used in the lighting industry: grid lights, street lights, fluorescent lights, tunnel lights and other lamp panel reflectors and other lighting materials. Welcome to leave message for the latest price and free sample.

The aluminum mirror strip is slotted, and the panel and the sideband are bonded with super glue to form a three-dimensional shell. The inner groove of the shell is usually poured with a layer of resin at the junction of the sideband and the panel to increase the adhesion between the sideband and the panel.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China