1060 Aluminum vs. 3003 Aluminum

1060 and 3003 aluminum are two common alloys. How to distinguish them? There are four tips. Also welcome to inquire 3003 aluminum sheet price.

1060 and 3003 aluminum sheet are two commonly used aluminum sheets, but they have different properties and applications. How to distinguish them by some simple methods? Haomei Aluminum tells you.

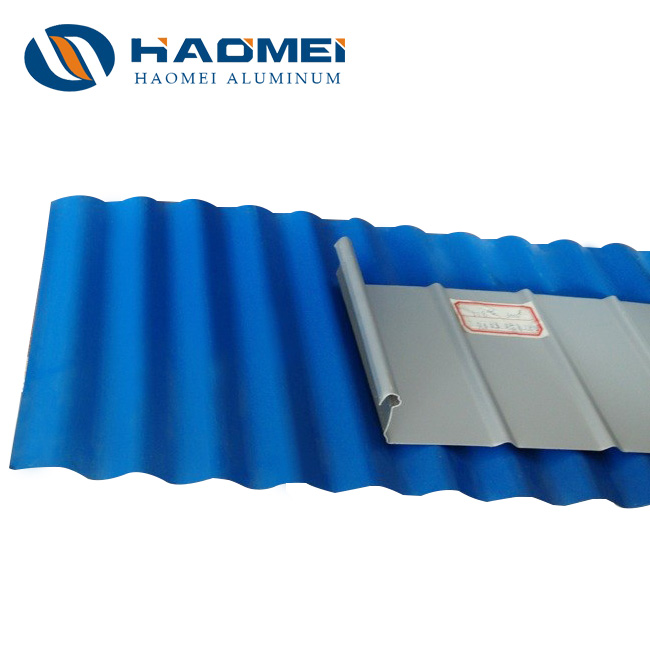

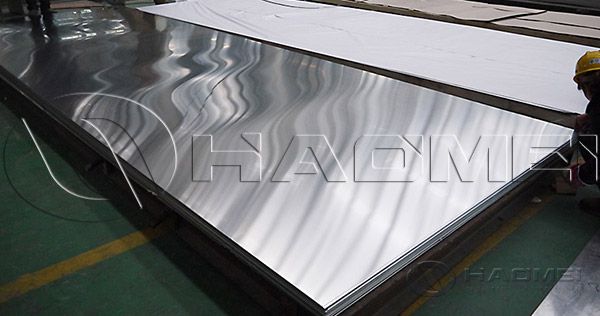

Surface color

Since the 3003 aluminum contains about 1.0-1.8% of manganese, the surface of the 3003 aluminum sheet will be grayish, especially under the outdoor sunlight. The 1060 aluminum belong to pure aluminum, which has a bright color.

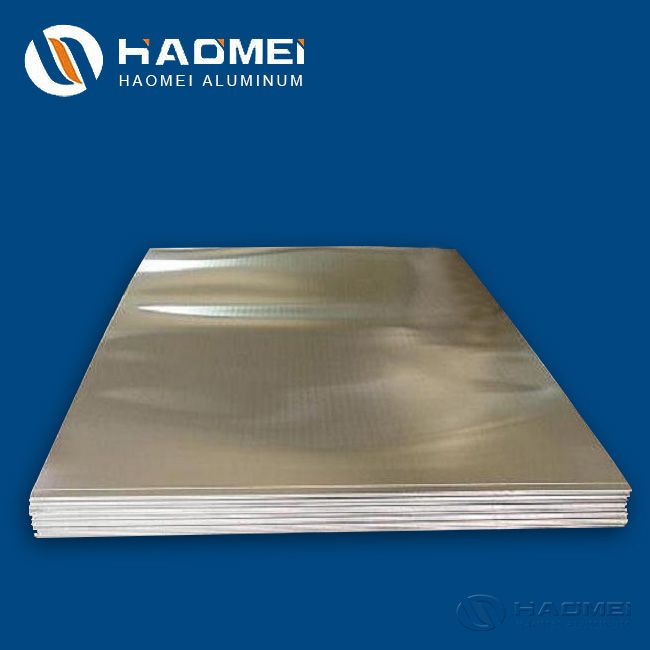

Hardness

With the same temper, the 3003 aluminum is much harder than the 1060 aluminum. If you have a hardness testing instrument, you can clearly find this point. The hardness of the 3003 aluminum plate is generally in the range of 30-35. But because the 1060 aluminum plate contains as much as 99.60% aluminum, the 1060 aluminum is about 10% softer than the 3003 aluminum.

Spectrometer

It is a normal way to use spectrometer data to analyze 3003 and 1060 aluminum. This is a relatively fast and the most formal and stable analysis method among these several methods.

Typical applications

The 3003 aluminum plate is suitable for building exterior walls, automobile lining, bus bottom lining, product packaging,etc. The 1060 aluminum is more commonly used in such fields like pipe insulation, ceiling, lamp stamping, transformer winding,etc.

As a big aluminum alloy supplier, Haomei Aluminum has both of them. Welcome to leave message below to get the 1060 and 3003 aluminum sheet price.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China