Why Is 5005 Anodized Aluminum Sheet So Popular

Why is 5005 anodize aluminum sheet so popular? It has better corrosion resistance and decorative performance. Find its other advantages from anodized aluminum sheet suppliers.

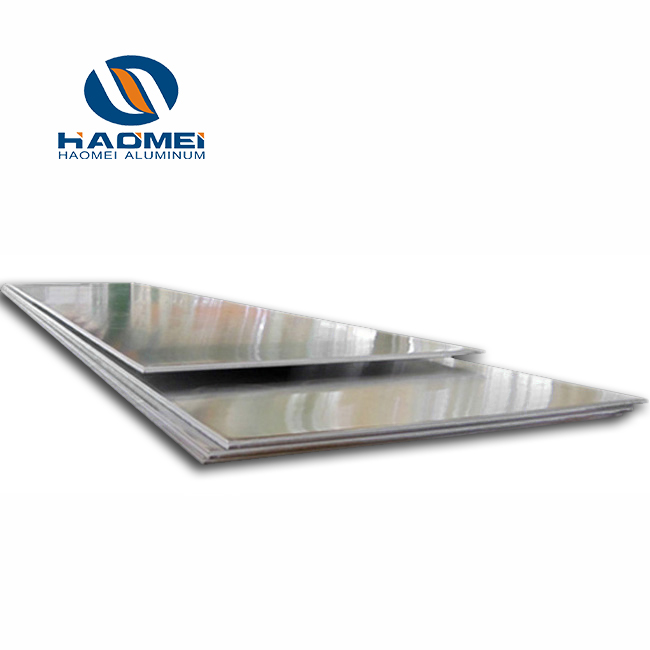

5005 aluminum sheet is widely used in shipbuilding and construction. The the surface treatment methods of aluminum are also various, including anodizing treatment, chemical conversion treatment, micro-arc oxidation treatment, electroplating treatment, electroless plating treatment,etc. But 5005 anodized aluminum sheet is more popular. Why? Find the answer below.

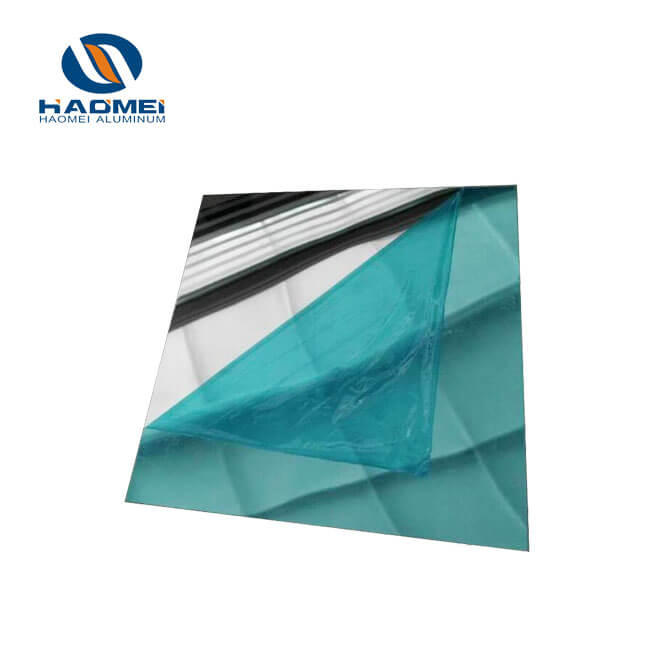

The anodizing coating has rich functions such as wear-resistant layer, electrical insulation layer, paint spraying bottom layer and electroplating bottom layer. The anodised aluminum plate has better corrosion resistance and strong decorative performance.

1. Preventing corrosion of aluminum sheet

Since the film layer obtained by anodization itself has sufficient stability in the atmosphere, the oxide film on the aluminum surface can be used as a protective layer. It has stronger corrosion resistance.

2. Decorative function

After chemical or electrochemical polishing, anodizing with sulfuric acid solution can obtain an oxide film with high transparency. This oxide film can absorb many kinds of organic dyes and inorganic dyes, and thus has a variety of bright colors. This color film is both an anti-corrosion layer and a decorative layer.

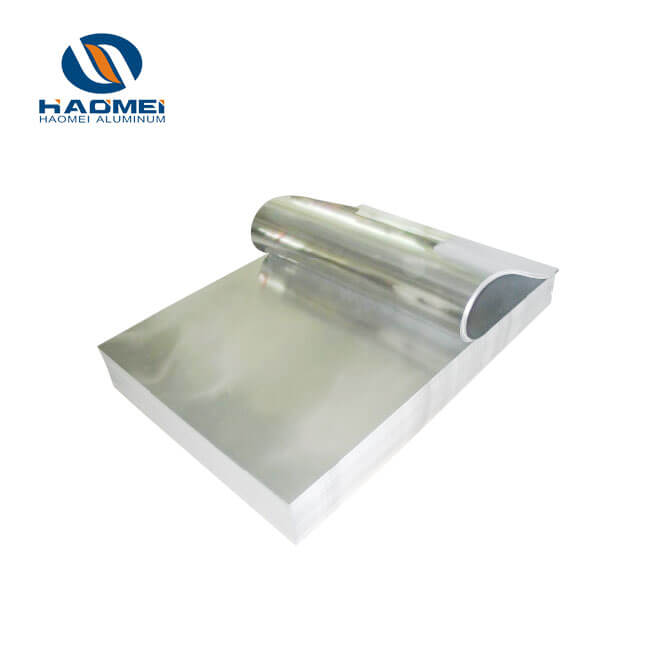

3. A hard wear-resistant layer

By hard anodizing, 5005 aluminum sheet can get a thick and hard Al2O3 film layer. This film layer not only has high hardness and thickness, but also has low roughness. Porous thick oxide film can store lubricating oil, so it can be used for making engine cylinders and pistons of cars and tractors.

4. Act as an electrical insulating layer

The oxide film obtained by anodizing has a large electric resistance, so it has a certain effect on improving the electrical insulation of certain products.

5. The bottom layer of the spray paint

Due to the porosity and good adsorption capacity of the anodized film, it can be used as the bottom layer of the spray paint and other organic films, so that the paint film and the organic film are firmly combined with the aluminum sheet, thereby increasing its corrosion resistance.

6. The bottom layer of electroplating

The aluminum alloy sheet must be applied with a bottom layer before electroplating. There are many methods for applying the bottom layer on the surface of the substrate. Anodizing is one of the important methods.

As an anodized aluminum sheet suppliers, Haomei can offer you many differ alloys of aluminum sheets with different thickness such as 3mm and 6mm. Welcome to inquire the price from us directly.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China