What Is The Process of Aluminum Sheet Fabrication

The basic process of aluminum sheet fabrication roughly includes raw material preparation, hot rolling, annealing, cold rolling, heat treatment, inspection,etc. What should be noticed? Learn more.

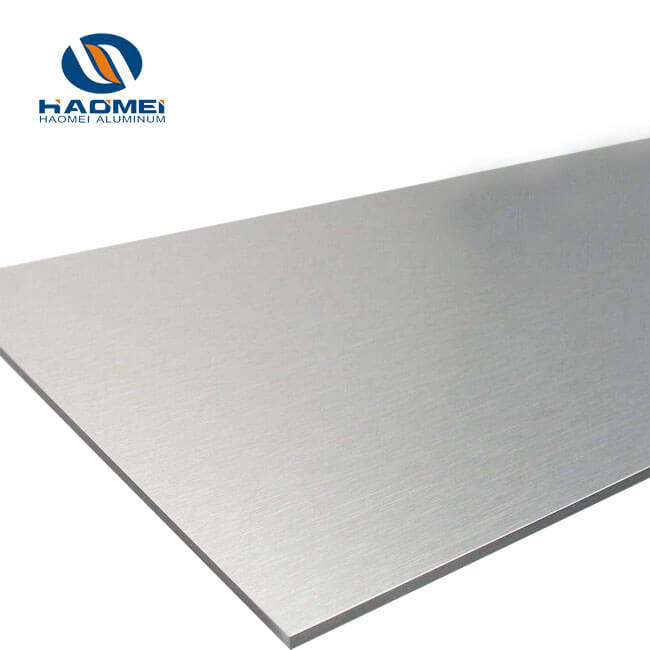

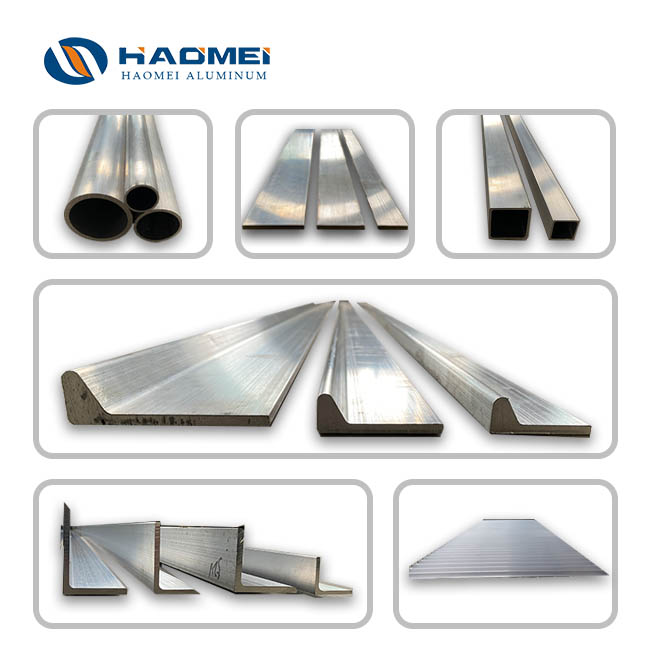

The thickness of the aluminum plate is up to 200mm, and it is divided into thin plate, thick plate (5-80mm) and extra thick plate. The width of the aluminum plate is generally 1-2.5m, up to 5m, and the length is 2-10m. The thickness of the aluminum strip is generally not more than 2mm, the width does not exceed 600mm, and it is supplied in coils.

The basic process of aluminum sheet fabrication roughly includes: homogenization treatment of ingots, preparation before hot rolling, heating, hot rolling, intermediate heat treatment (annealing), cold rolling, finished product heat treatment, finishing, inspection, packaging, etc. The following is a general aluminum plate production process, and what to pay attention to in each step:

1. Raw material preparation: The main raw material of aluminum plate is aluminum alloy. Select the appropriate type of aluminum alloy, determine the chemical composition and performance requirements to meet the needs of the final product.

2. Casting: Aluminum alloys can be prepared by casting methods. The alloy ingredients should be accurate according to the required performance. The melting temperature and time must be appropriate to ensure the uniformity of the aluminum alloy.

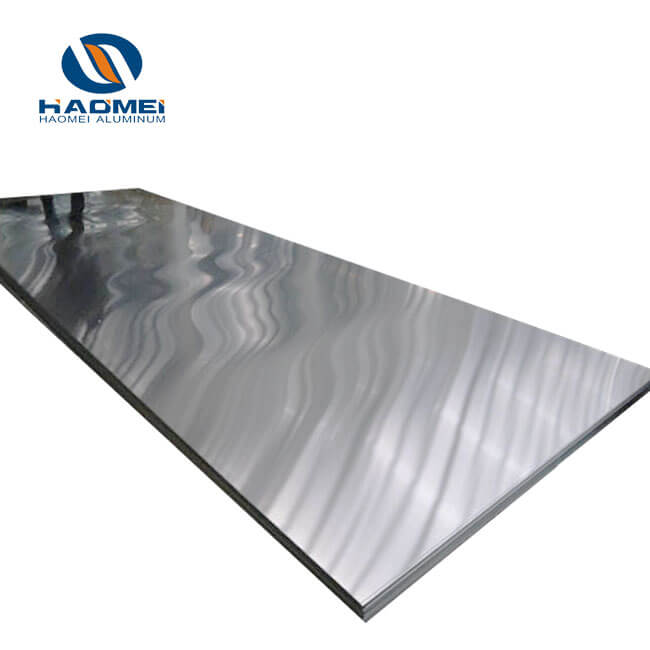

3. Rolling: Aluminum alloy is continuously rolled through a rolling mill to form the required aluminum plate thickness. The rolling temperature needs good control to ensure the micro-structure and mechanical properties of the alloy. The worker should adjust accurately the parameters of the rolling mill to obtain the required plate size and surface quality.

4. Annealing: Annealing is the heat treatment of aluminum plates during the rolling process to eliminate stress and improve the machinability of the material. Determine the appropriate annealing temperature and time according to the composition and performance requirements of the material. A good control of the cooling rate can avoid the generation of undesirable grain boundary structures.

5. Cutting: Cut the aluminum sheet into the required size and shape. Select appropriate cutting tools to ensure accurate and smooth cutting edges. Pay attention to safety during cutting to avoid personal injury and material waste.

6. Surface treatment: The aluminum plate is surface treated, such as anodizing, coating, etc., to improve its corrosion resistance and decorative properties. Haomei Aluminum has a good control of the parameters of the processing process according to the required surface effect.

Different coatings lie PE or PVDF coating are used to meet the different performance requirements.

7. Inspection and quality control: Perform quality inspection on the aluminum plate to ensure that it meets the technical requirements and standards. We will check the dimensions, flatness and surface quality to ensure product quality. We also do chemical analysis and mechanical properties tests to ensure that the product meets the requirements.

8. Packaging and delivery: The aluminum sheet is properly packaged to prevent damage and corrosion, and then shipped out of the factory.

During the entire aluminum sheet production process, the following points need to be noted:

Safe operation: Maintain safe operation in all steps and follow relevant safety standards and operating procedures.

Process parameter control: Control the parameters of each process step to ensure product consistency and quality.

Environmental protection: Adopt environmentally friendly production methods and reasonably handle waste and sewage.

Quality management: Implement strict quality control and inspection to ensure that the product meets customer needs and standard requirements.

Please note that different types of aluminum sheets (such as 4x8 aluminum sheet, anodized aluminum sheet, coated aluminum sheets, etc.) may have different steps and precautions in the production process. The specific production process and precautions may vary depending on the manufacturer, material and product requirements. Welcome to inquire the 4x8 sheet of 1 8 inch aluminum price from us.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China