What Are Three Physical Properties Of Aluminum Foil

There are significant differences in the physical properties of different aluminum foil types like strength, hardness, tensile strength, ductility,etc. What are these differences? Learn more.

In modern industry and daily life, aluminum foil can be seen everywhere. From food packaging to electronic equipment heat dissipation, it plays an important role with its unique physical properties. However, there are significant differences in the physical properties of different aluminum foil types, which determine their applicable scenarios.

Strength and hardness: Comparison between packaging aluminum foil and industrial aluminum foil

Packaging aluminum foil usually pays more attention to flexibility and sealing, and its strength and hardness are relatively low. Taking food packaging aluminum foil as an example, its main function is to isolate oxygen, moisture and light, and protect the freshness of food.

Therefore, it will undergo sufficient annealing during the production process to make it soft, easy to fold and shape, and convenient for wrapping various foods. The tensile strength of this type of aluminum foil is generally between 80-130MPa, and the hardness is relatively low. A light scratch with a fingernail can leave a mark.

The industrial aluminum foil such as aluminum foil for aerospace structural parts and automotive parts, has extremely high requirements for strength and hardness. These aluminum foils will undergo special processing techniques, such as cold working strengthening and aging treatment, to improve their mechanical properties.

The tensile strength of aluminum foil for aerospace can reach 400-600MPa, and the hardness is greatly improved. It can withstand large external forces and stresses, while ensuring lightweight and meeting the requirements of structural strength.

Ductility: The different performances of pure aluminum foil and alloy aluminum foil

Pure aluminum foil has excellent ductility, which is due to the regularity of the arrangement of pure aluminum atoms and the relatively weak interatomic bonding force. During the processing, pure aluminum foil can be rolled very thin, even to a thickness of less than 6 microns, and is not easy to break under operations such as stretching and bending.

For example, the aluminum foil in cigarette packaging uses the high ductility of pure aluminum foil to fit cigarettes tightly and form a good packaging effect.

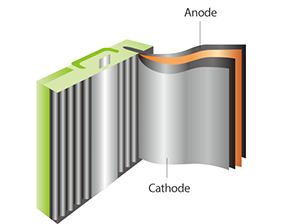

The ductility of alloy aluminum foil will be affected to a certain extent due to the addition of other metal elements. For example, although the strength of aluminum foil containing alloy elements such as magnesium and manganese has been improved, its ductility has decreased compared with pure aluminum foil.

However, this alloy aluminum foil has unique advantages in some fields that have comprehensive requirements for strength and ductility, such as capacitor manufacturing. It can not only ensure a certain mechanical strength to prevent deformation during the production process, but also be stretched and formed to a certain extent to meet the manufacturing process requirements of capacitors.

Thermal conductivity: Differences in thermal conductivity of aluminum foils of different thicknesses

The thermal conductivity of large roll aluminum foil is closely related to its thickness. Generally speaking, thicker aluminum foil has relatively better thermal conductivity because its internal heat conduction channel is more continuous and unobstructed. In the field of industrial heat dissipation, thicker aluminum foil is used to make heat sinks to quickly conduct heat away. For example, the aluminum foil heat sink used in computer CPU radiators is usually between 0.3 and 1 mm thick and can efficiently transfer the heat generated by the CPU to the air.

Although the thermal conductivity per unit area of thinner aluminum foil remains unchanged, the efficiency of heat transfer will be affected in some cases due to the shortened heat conduction path. Ultra-thin aluminum foil, commonly used in food packaging, may be only 10 to 20 microns thick and mainly serves as heat insulation and moisture-proof. Compared with thick aluminum foil, its thermal conductivity is weaker in heat dissipation.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China