What Are Types of Pharmaceutical Blister Foil

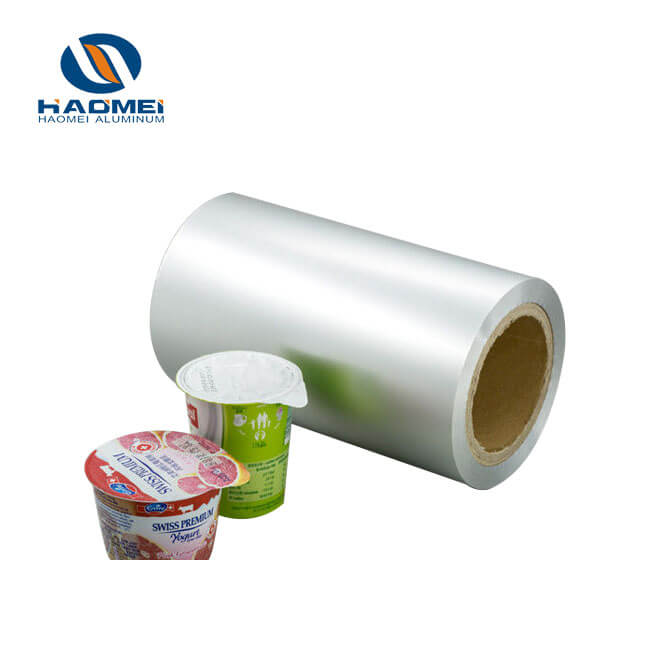

In the pharmaceutical packaging industry, pharmaceutical blister foil plays a crucial role in ensuring drug quality and extending its shelf life.

In the pharmaceutical packaging industry, pharmaceutical blister foil plays a crucial role in ensuring drug quality and extending its shelf life. It forms a sealed packaging space with the blister sheet, effectively isolating harmful substances such as oxygen, moisture, and light, preventing moisture, oxidation, and contamination. It also clearly labels drug information, making it easier for patients to identify and use.

The substrate is a core component of pharmaceutical blister foil, directly impacting its physical properties, chemical stability, and compatibility with the drug. Depending on the substrate material, it can be primarily categorized into the following two types:

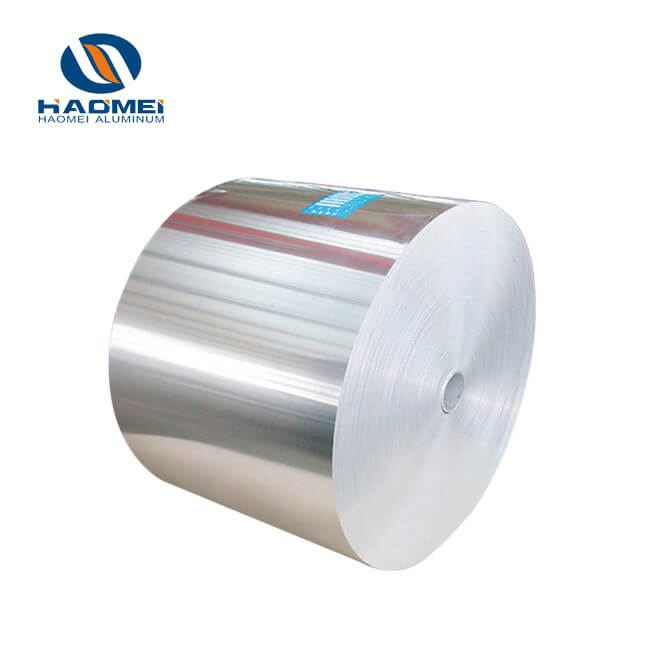

Aluminum Foil

This type of ptp blister foil is currently the most widely used in the pharmaceutical blister foil market. Its base material is pure aluminum foil, typically with a thickness of 20-40μm. Pure aluminum foil offers excellent barrier properties, virtually completely blocking out oxygen, moisture, and light, effectively protecting pharmaceuticals. It is particularly suitable for pharmaceuticals with demanding storage requirements, such as easily oxidized vitamins and moisture-absorbing traditional Chinese medicine pills.

Aluminum foil also offers excellent ductility and formability, allowing it to adhere tightly to various blister sheets. Its surface is also easy to print on, allowing for clear imprinting of key information such as the drug name, strength, production date, and expiration date. However, pure aluminum foil is relatively soft and should be protected from crushing and impact during transportation and use, potentially causing damage.

Composite Blister Foil

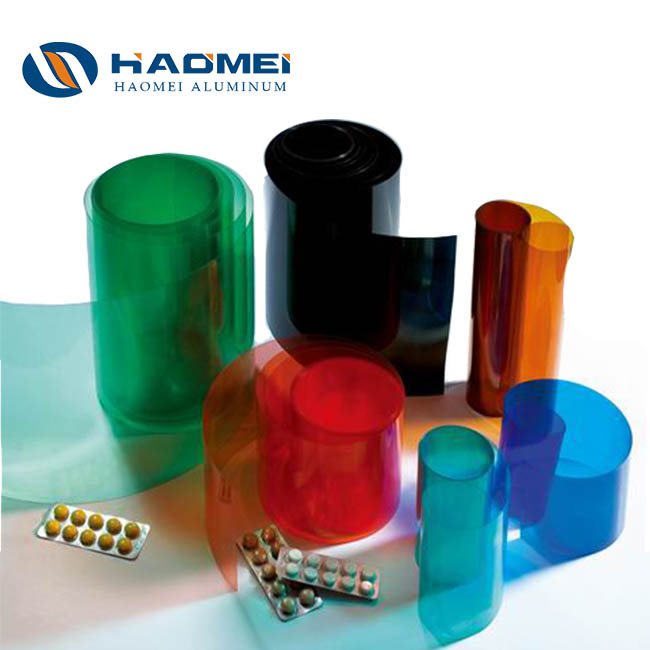

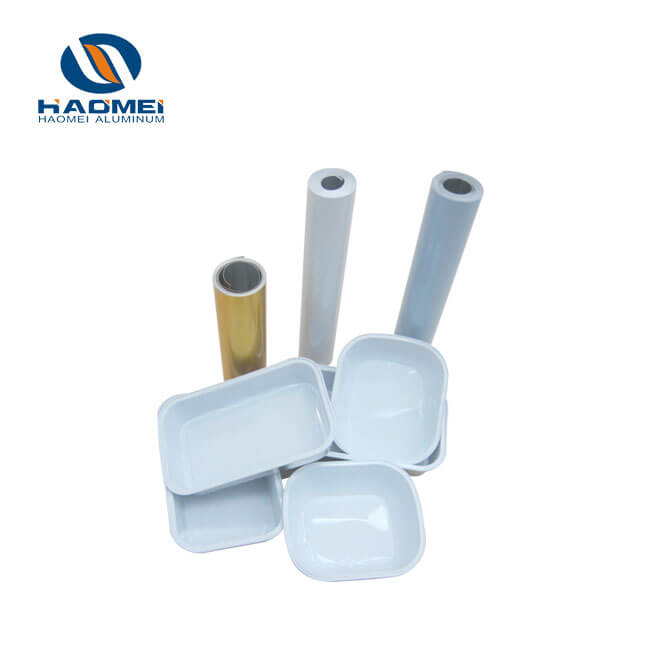

This type of blister foil is constructed from a composite of multiple materials, with common combinations including "aluminum foil + plastic film" and "plastic film + metallization." Aluminum foil + plastic film composite blister foil typically incorporates a layer of PET (polyethylene terephthalate) or PVC (polyvinyl chloride) film on the aluminum foil surface. This retains the excellent barrier properties of aluminum foil while enhancing the blister foil's stiffness and impact resistance through the plastic film, making it more suitable for high-speed automated packaging lines and commonly used for mass-produced pharmaceuticals such as tablets and capsules.

Composite blister foils made with a "plastic film + metal coating" are made by coating a plastic film with an extremely thin layer of metal (such as aluminum). While their barrier properties are slightly inferior to aluminum foil-based blister foils, they are lighter and less expensive. Some types also offer excellent transparency, allowing consumers to directly observe the appearance of the drug. They are suitable for packaging general pharmaceuticals or health supplements where barrier properties are not a high priority. Welcome to inquire different types of pharma foils from us directly.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China