The Development History of Aluminum Trim Coil in China

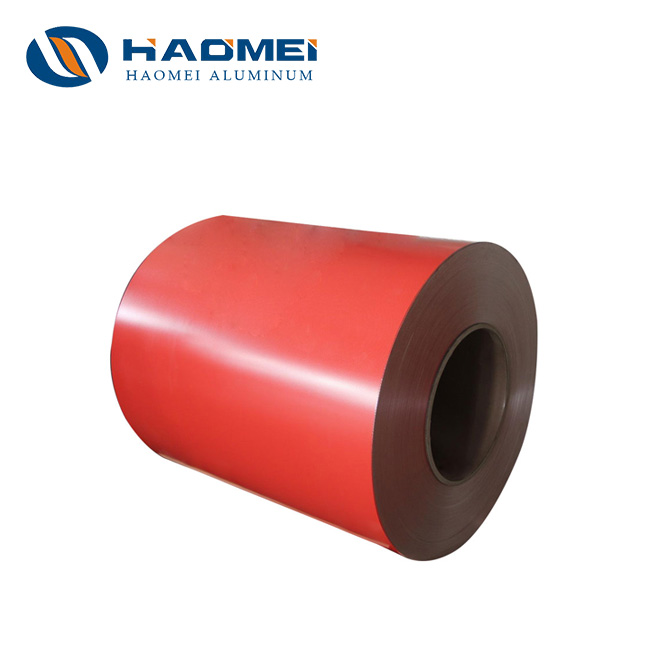

The production of aluminum trim coil in China has seen a history of about 50 years. The product colors and quality has been greatly richened and improved like wood grain and black one. Learn more.

Aluminum trim coil production line was developed from steel coil roller coating. China began to introduce them from the late 1980s to the early 1990s, and the first ones were all color steel plate production lines. In 1984, Guangdong introduced the first domestic production line dedicated to coating aluminum coils. Now there are rich colors for the customers to choose from like wood grain aluminum trim coil.

Features of roller coated aluminum

The color coated production line has the advantages of good continuity, high efficiency, high output, good quality, high utilization rate of raw materials and coatings, less loss, energy saving, low cost, good economic benefits, and less pollution. Currently the fastest speed of the high-speed color coating production line has reached 240m/min.

The production technology of aluminum alloy roller coating has been updated, and the precision coating machine combined with steel roller and rubber roller makes the equipment more sophisticated and the the product quality is better.

Advantages of roller coated aluminum

The purpose of aluminum roller coating is to make the paint form a firm continuous coating on the surface of aluminum and aluminum alloy, so as to play its role of decoration, protection and special functions. The aluminum coils and plates treated by roller coating can be directly processed by users to make various parts and products. After assembly or installation, they are finished products without further coating treatment.

That is to say, the traditional process of processing and forming first and then coating is changed to the process of coating first and then processing and coating, which simplifies the production process of metal plates into finished products and saves more than 2/3 of paint.

Application of aluminum trim coil

Aluminum trim coil like black aluminum trim coil has the advantages of beautiful appearance, weather resistance, corrosion resistance, stain resistance, strong decoration, and good processability. The main uses are as follows:

1. Construction material: roof, wall materials, awnings, doors, windows and shutters, ceilings and aluminum-plastic panels, etc.

2. Household appliances: air conditioners, heating and ventilation equipment, refrigerators and home appliances, stoves, kitchen utensils, electrical equipment, etc.

3. Transportation equipment: pre-painted car and ship shells, truck tray covers, car body parts, etc.

4. Packaging materials: packaging tanks and caps, food packaging, etc.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China