The Processing and Functions of Prefinished Aluminum Coils

The painted aluminum is much favored because of its protective, decorative and other function. How to get a better coating layer?As a painted aluminum coil manufacturer, Haomei tells you.

The painted aluminum coil is much favored by more and more customers because of rich colors and superior performance. What’s its functions?

1. Protection. Aluminum alloy will be eroded by oxygen, moisture, acids, salt mist, various corrosive gases, and ultraviolet rays during long-term exposure to air during use. A coating with a certain thickness (ie, a protective layer) is formed on the surface of aluminum coil will protect it from corrosion.

2. Decoration. The paint has many colors such as white, black, brown, gold, blue,etc. and it can even make a variety of three-dimensional texture effects, such as orange peel. With attractive appearance and special properties, prefinished aluminum coils play a role in beautifying our living environment.

3. Other functions. In addition to protection and decoration, the coating also has many special functions, such as electrical insulation, static electricity conduction, anti-fouling, heat resistance, wear resistance, heat preservation, reflection, anti-noise, shock absorption, anti-skid, anti-UV, etc. These special functions of the coating enhance the performance of the product and broaden the scope of application of the color coated aluminum coil.

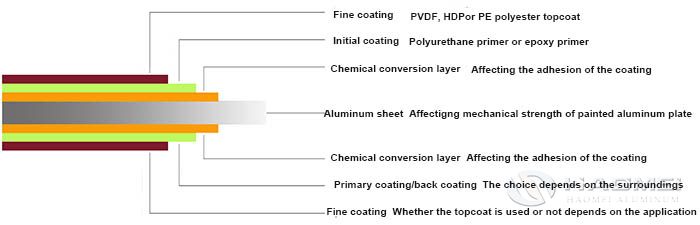

Then how to get a better coating effect? Its coating process can be divided into three coating process, two coating process and single coating process according to the number of coating layers.

According to the rotation direction of the coating roller and the driving roller, it can be divided into two processes of forward coating and reverse coating. The forward coating process can only produce a lower wet film thickness, and the surface appearance of the coating film produced by this process is not ideal, so the process is not very used.

The reverse coating process is currently a widely used coating process. By adjusting the rotation ratio between the rollers and the traveling speed of the substrate, a coating film with a desired thickness and a smooth appearance can be obtained.

As a big painted aluminum coil manufacturer, Haomei Aluminum has the advanced processing technology and equipment for a better quality.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China