Marine Grade Aluminum Plate Alloys and Applications

What are the common marine grade aluminum plates and what’s their role in ship building? Here is the comprehensive introduction of 5052, 5083, 5086, 6061,etc. Learn more.

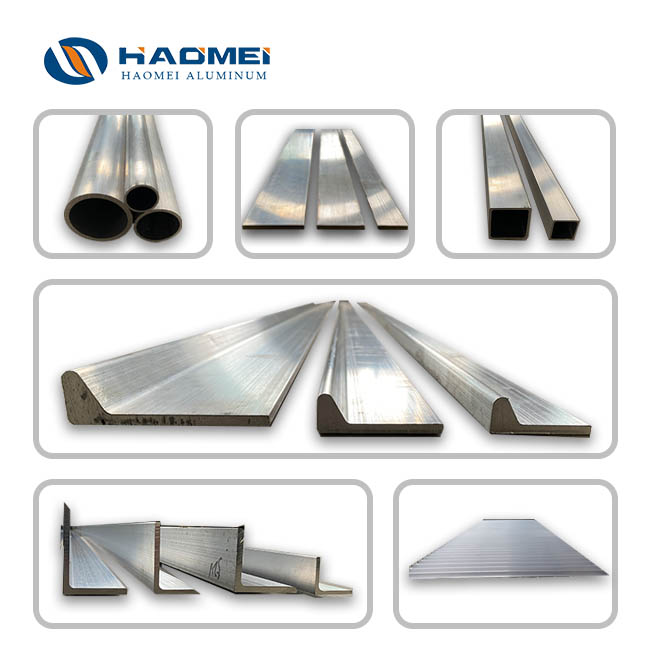

Marine grade aluminum plate can be wrought aluminium alloy and cast aluminum alloys according to different manufacturing processes. Because marine grade aluminum has special requirements on strength, corrosion resistance, weldability, etc., it mostly use Al-Mg, Al-Mg-Si and Al-Zn-Mg aluminum alloy. Of them, Al-Mg aluminum alloy is most widely used on ships.

According to the application, marine grade aluminum sheet can be aluminum alloys for hull structures and for outfitting. The aluminum alloys used for ship hull structures are mainly 5083, 5086 and 5456.

6000 series alloy can be used in the superstructure of ships because it has inter-granular corrosion when it directly contacts with sea water. The strength and process performance of the 7000 series alloy after heat treatment are superior to the 5000 series alloy, so it can be used in naval superstructures, such as compression structures and armor plates. However, the shortcoming of 7000 aluminum alloy is its poor resistance to stress corrosion, so it limits the use of this series.

This table shows the elements, properties and applications of different marine grade aluminum sheet. If you like to know marine grade aluminium sheet price, welcome to contact Haomei Aluminum directly.

Items | Alloy | Temper | Chemical element | Properties | Application |

For Hull | 5052 | O H14 H34 | Al:remainder Si:≤0.25 Cu:≤0.10 Mg:2.2~2.8 Zn:≤0.10 Mn:≤0.10 Cr: 0.15-0.35 Fe:≤0.40 | Medium strength, good corrosion resistance and formability, high fatigue strength | Superstructure, auxiliary components, boat hull |

5083 | O H32 | Al:reminder Si:≤0.40 Cu:≤0.10 Mg:4.0-4.9 Zn:≤0.25 Mn:0.40~1.0 Ti:≤0.15 Cr:0.05-0.25 Fe:0-0.400 | good weldability, corrosion resistance and low temperature performance, highest strength among non heat-treated aluminum alloys | Main structure of hull | |

5086 | H32 H34 |

Al:remainder Si:≤0.40 Cu:≤0.10 Mg:3.5-4.5 Zn:≤0.25 Mn:0.20-0.7 Ti:≤0.15 Cr:0.05-0.25 Fe:0-0.500 | The weldability and corrosion resistance are the same as 5083, and the strength is slightly lower, and the extrudability is improved. | The main structure of the hull | |

5454 | H32 H34 | Al:remainder Si:≤0.25 Cu:≤0.10 Mg:2.4-3.0 Zn:≤0.25 Mn:0.50-1.0 Ti:≤0.20 Cr:0.05-0.20 Fe:0.000-0.400 | It has 22% higher strength than 5052, good corrosion resistance and weldability, general formability | Hull structure, pressure vessel, pipeline, etc. | |

5456 | O H321 | Al:remainder Si:≤0.50 Cu:3.8-4.9 Mg:1.2-1.8 Zn:≤0.30 Mn:0.30-0.9 Ti:≤0.15 Ni:≤0.10 Fe:0.000-0.500 Fe+Ni:0.000-0.500 | It is Similar to 5083, but with slightly higher strength and sensitivity to stress corrosion | Hull and deck | |

6061 |

T4 T6 | Cu: 0.15-0.4 Mn: 0.15 Mg: 0.8-1.2 Zn: 0.25 Cr: 0.04-0.35 Ti: 0.15 Si: 0.4-0.8 Fe: 0.7 Al: remainder | It can be strengthened by heat treatment. It has high strength, but the welding seam has low strength. It is mainly used for screwing and riveting structures that are not in contact with seawater. | Superstructure, partition structure, frame, etc. | |

For outfitting |

1050

1200 | H112O H12 H24 | Al:remainder Si:≤0.25 Fe:0.40 Cu:≤0.50 Mn:≤0.50 Mg:≤0.50 Zn:≤0.15 Ti:≤0.03 | Low strength, good workability, good weldability and corrosion resistance, high surface treatment | Interior decoration |

Cu:≤0.50 Mn:≤0.50 Zn:≤0.15 Ti:≤0.03 Fe+Si:≤1.0 | |||||

3003

3203 | H112O H12 | Al :remainder Si:≤0.60 Fe:≤0.70 Cu:≤0.50 Mn:1.0~1.5 Zn:≤0.10 | It has 10%higher strength than 1100, good formability, weldability, and corrosion resistance | Interior decoration, top and side plates of LPG tank |

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China