How to Test Quality of The Wholesale Painted Aluminum Coil

The color painted aluminum coil is of wide applications. How to ensure its quality? There are physical test and visual test. The physical test includes film thickness, color test, adhesion,etc. Learn more.

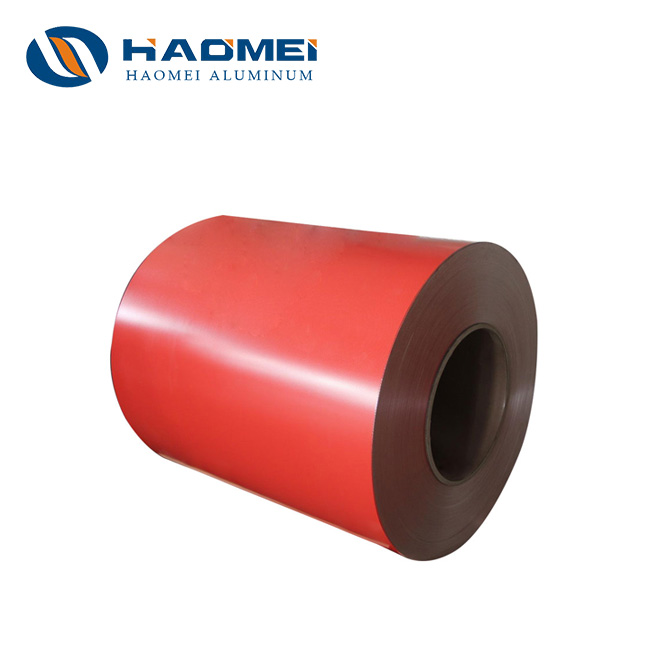

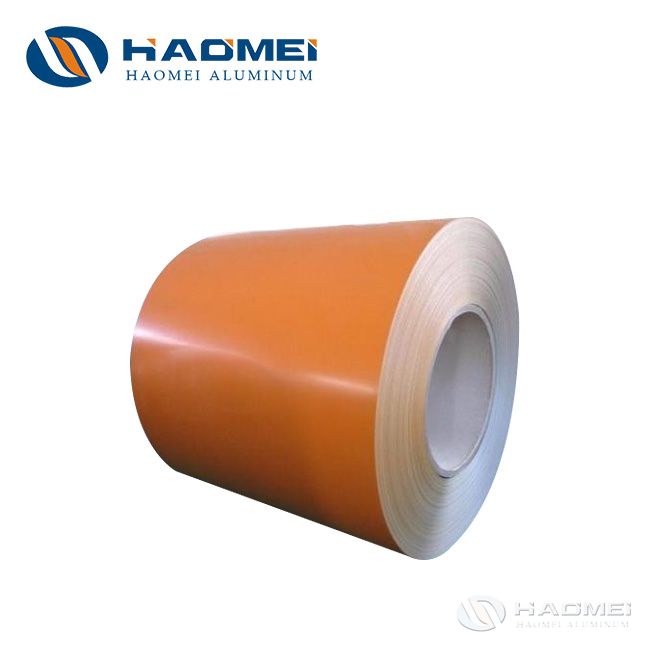

The color painted aluminum coil has excellent corrosion resistance, durability and light weight. It is widely used in public buildings, power plants, steel mills, chemical industry and other industries. We have pre-painted aluminum coils with different aluminum alloys as base metals. The colors and patterns depends on your needs.

Physical test

It is important to carry out a physical inspection to see if the paint has been painted and the coil has been properly cured before being placed on the market for use.

1. Film thickness

For the color coated aluminum coil, the detection of film thickness is very important, because it will affect the performance of the paint film. Poor adhesion or premature corrosion can result if the first coat is not done properly. If the finish is left unfinished, it can cause premature failure and damage due to weathering.

A thin film coating that is too thin will affect the durability and performance of the aluminum coil. It can be tested by a coating thickness gauge. The coating film thickness gauges are used to calculate performance, quality and cost.

2. Color test

The pre painted aluminum coils must maintain standard color to satisfy customers. Most of the time, if there is a specific requirement for a specific color, it is important to provide the same color in the final product. Therefore, the consistency of matching shades from run to run is critical.

A few factors that you must consider that affect color quality are film thickness, substrate color, curing temperature and coating formulation.

3. Gloss

Gloss adds luster to color coated aluminum coils and gives them a uniform appearance. The coated aluminum coil production includes many processes. It is is necessary to check the consistency of gloss in the aluminum coil.

4. Adhesion

The coating consists of various adhesives and resins. This test is performed to check T-bend, impact and scratch resistance.

Vision Test

After the physical inspection, it's time for a visual inspection. Here are a few ways you can perform a visual inspection test.

1. Different appearance standards

Since prepainted aluminum coils are so versatile, it is important to test whether the aluminium coil is suitable for the application. Therefore, you must perform quality checks by visual inspection according to the industry of use.

2. Defects

The color difference, aluminum sheet damage or inconsistent thickness can affect the performance of the wholesale painted aluminum coil. Perform visual tests to make sure the panels work for different applications.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China