All About Color Aluminum Coil 24x50

What do you like to know about the color aluminum coil? Its manufacturing process? Qualified painting thickness? Painting process and equipment? When should it be painted one side or both sides? Learn more.

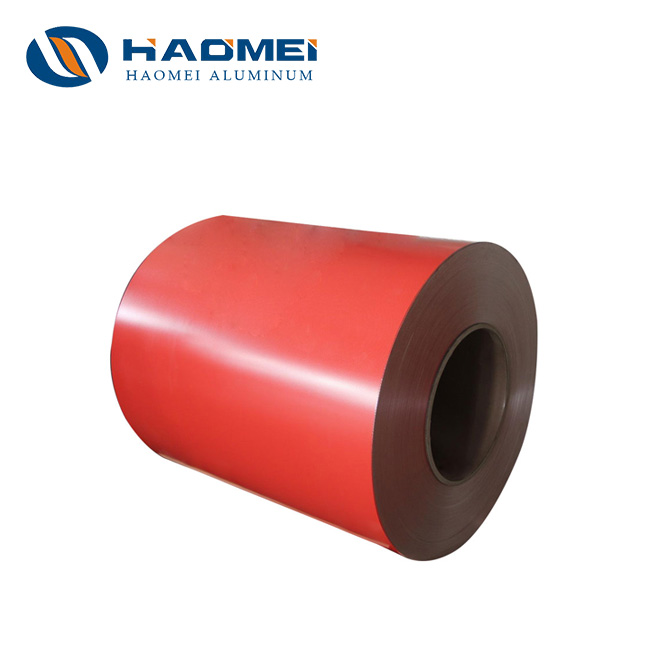

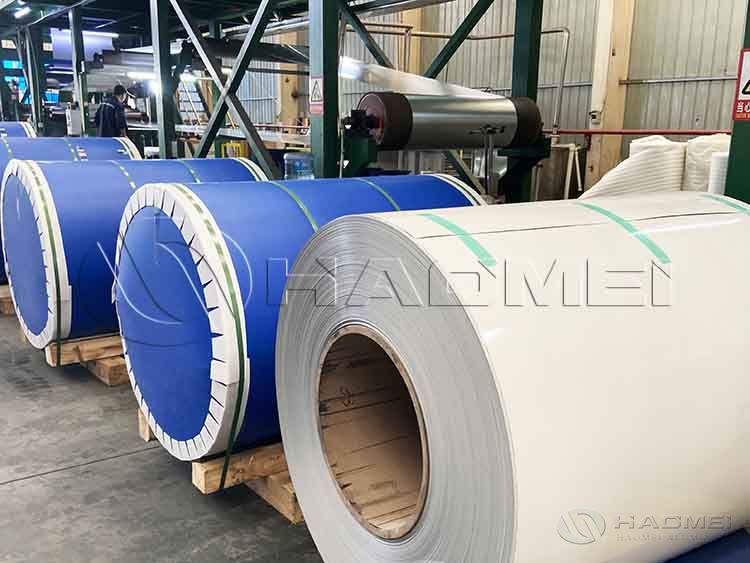

The color aluminum coil is a versatile and durable material that can be used in a variety of applications such as roofing, siding, gutters, decoration, cans, bottles, appliances, electronics, and more. Compared with other metals, color coated aluminum coils have many advantages, such as corrosion resistance, light weight, high reflectivity, easy to shape, and recyclable.

Manufacturing process

The pre-painted aluminum coils usually use a two-coating and two-baking process, that is, after the surface pretreatment of the aluminum coil, the primer (primary coating) and topcoat (finishing coating) are applied and baked twice, and cured as needed.

The various layers of paint on pre-painted aluminum coils and their names, thicknesses and uses are as follows:

The primer layer is a layer of basic paint applied on the surface of the aluminum coil after pretreatment to enhance adhesion and corrosion resistance, usually with a thickness of 5-10 microns。

The topcoat layer is on the primer layer. Organic coatings of different colors and glossiness are selected according to the needs to form the main appearance characteristics of the color-coated aluminum coil. The thickness is usually 15-25 microns.

Back coating is to apply a layer of organic coating, usually anti-rust paint or protective paint, on the back side of the aluminum coil (that is, the side opposite to the base material) to enhance the corrosion resistance and weather resistance of the pre-painted aluminum coil. The back coating is typically 5-10 microns thick.

Paint thickness

The coating thickness of the color coated aluminum coils is one of the important factors affecting its performance and quality. Paint thickness that is too large or too small will cause defects and problems in color-coated aluminum coils. Excessive paint thickness will increase costs, reduce the hardness and flexibility of the coating, affect the adhesion and corrosion resistance of the coating, and easily cause defects such as sagging, wrinkles, and bubbles.

If the paint thickness is too small, the coverage and hiding power of the coating will be reduced, the color and gloss of the coating will be affected, and defects such as scratches, wear, and peeling will easily occur.

Painting process and equipment

Different painting processes and equipment have different control accuracy for paint thickness. According to different coating methods, there are roller coating method, spray coating method, powder method, lamination method, printing method, etc. Among them, the roller coating method is the most commonly used method. It uses a roller to evenly distribute the pre-mixed paint on the substrate, and forms a continuous and uniform paint film through baking and solidification. The shape, size, rotation speed, gap and other parameters of the roller will affect the amount of roller coating, thereby affecting the coating thickness of the final product.

Deep processing of color aluminum coil

The embossed or printed layer is formed on the topcoat layer or backcoat layer through pressure or heat transfer to form different patterns and textures, such as solid color, imitation stone, imitation wood grain, imitation bamboo grain, etc., to increase the decorative and aesthetic properties of pre-painted aluminum coils.

According to different uses and requirements, pre-painted aluminum coils can also choose different types of coatings, such as polyester, fluorocarbon, silicone polyester, etc., as well as different coating types, such as single-sided painting and double-sided painting.

Single-sided painting refers to coating only one side of the aluminum coil with organic paint, while the other side maintains the original aluminum color or is coated with anti-rust paint. This type of pre-painted aluminum coil is mainly used for roofs, walls and other occasions where double-sided display is not required.

Double-sided painting refers to coating both sides of the aluminum coil with organic paint to form different or the same colors and patterns. This type of aluminum trim coil 24x50 is mainly used for ceilings, doors, windows, curtain walls and other occasions that require double-sided display.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China